Sullair Compressor Cooler TRE60

The advanced cooling solution for industrial centrifugal compressors by Fete Vessel

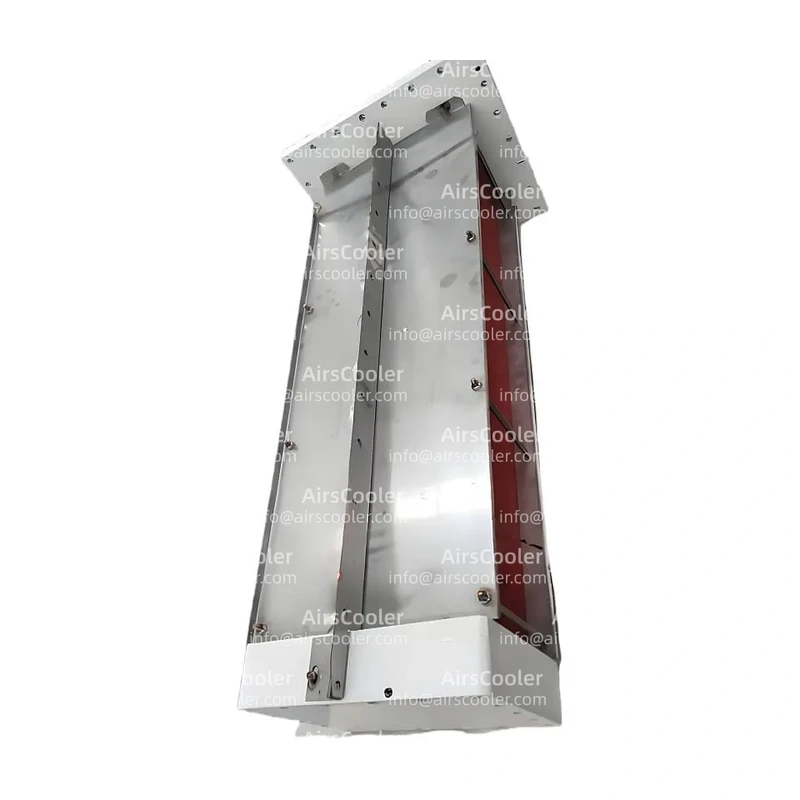

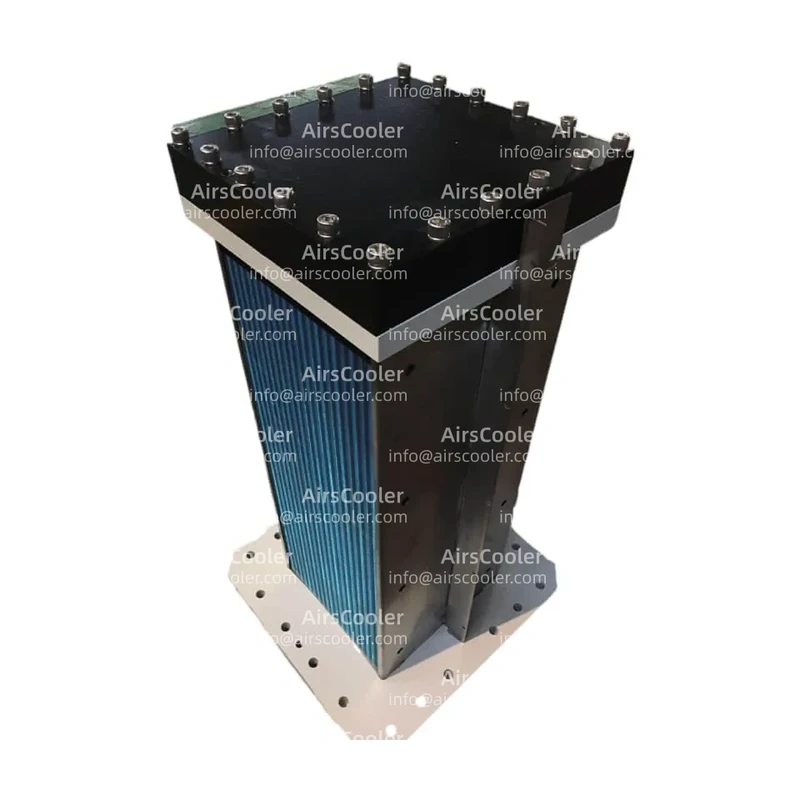

1. Product Overview: Core module of Centrifugal Compressor Cooling system setup

The Sullair Compressor Cooler TRE60 is an integrated heat exchange unit specifically built for IHI-Sullair TRE series centrifugal compressors. As a core module of the TRE60 model (rated power 560kW, displacement 6300m³/h), its primary function is to efficiently transfer heat generated during compression through water cooling, ensuring stable operation within the 8-16bar pressure range.

This cooler adopts modular design principles, forming an integrated structure with the compressor main body, gearbox, intercooler, and aftercooler, reducing equipment footprint by 35% compared to traditional offerings while achieving low-noise operation at 76±3dB.

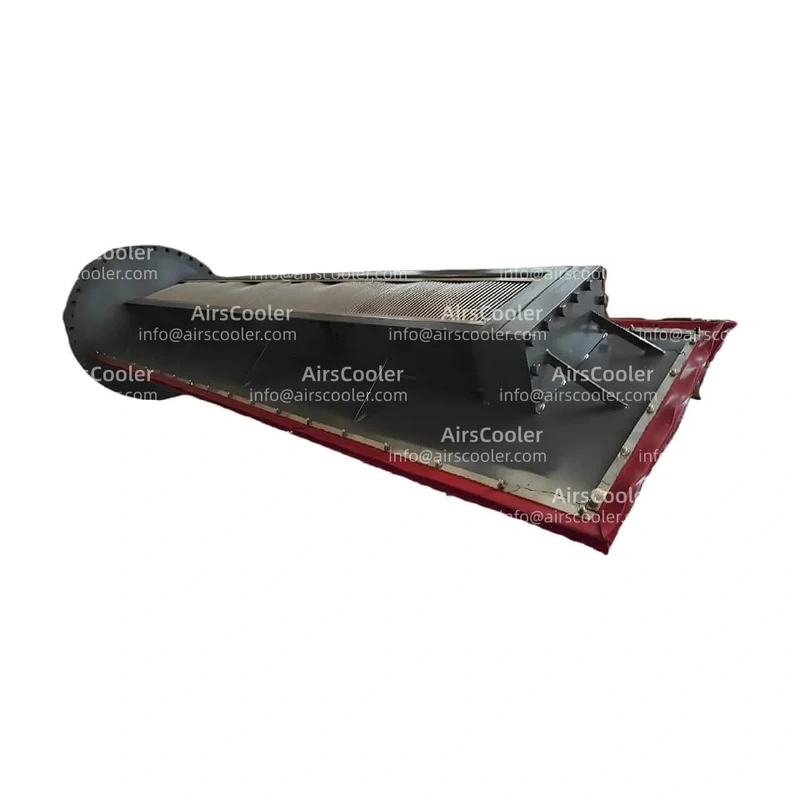

From a technical evolution perspective, the TRE60 cooler inherits the through-tube water cooling technology jointly developed by Sullair and IHI Group. By completely isolating the cooling water channel from the air circuit, it eliminates the risk of oil-water mixing common in traditional coolers. Its structural design is based on aircraft engine thermal management concepts, with cooling water flowing through the shell side and compressed air through the tubes, combined with numerically controlled titanium alloy heat exchange tube bundles, improving heat exchange overall efficiency by 22% compared to previous generation products.

2. Technical Features and Data Specifications

2.1 High-overall efficiency Heat Exchange system setup

Titanium Alloy Heat Exchange Matrix: Uses TA15 titanium alloy tube bundles processed by CNC five-axis machining, with tube wall thickness precisely controlled at 1.2mm. Combined with spiral fin structure, single-tube heat exchange area reaches 0.85m²/m, with 40% better corrosion resistance than copper tube bundles.

Water-Side Fluid Dynamics Optimization: Cooling water inlet velocity is designed at 2.3m/s, outlet velocity at 1.8m/s. Combined with an 80A standard pipe diameter forced circulation system setup, at 32°C inlet water temperature, it can minimize exhaust temperature from 220°C to below 45°C.

Intelligent Temperature Control Algorithm: The PID adjustment module integrated into the main control system setup can automatically adjust cooling water flow according to load changes, saving 12% energy compared to constant flow systems at 70% load conditions.

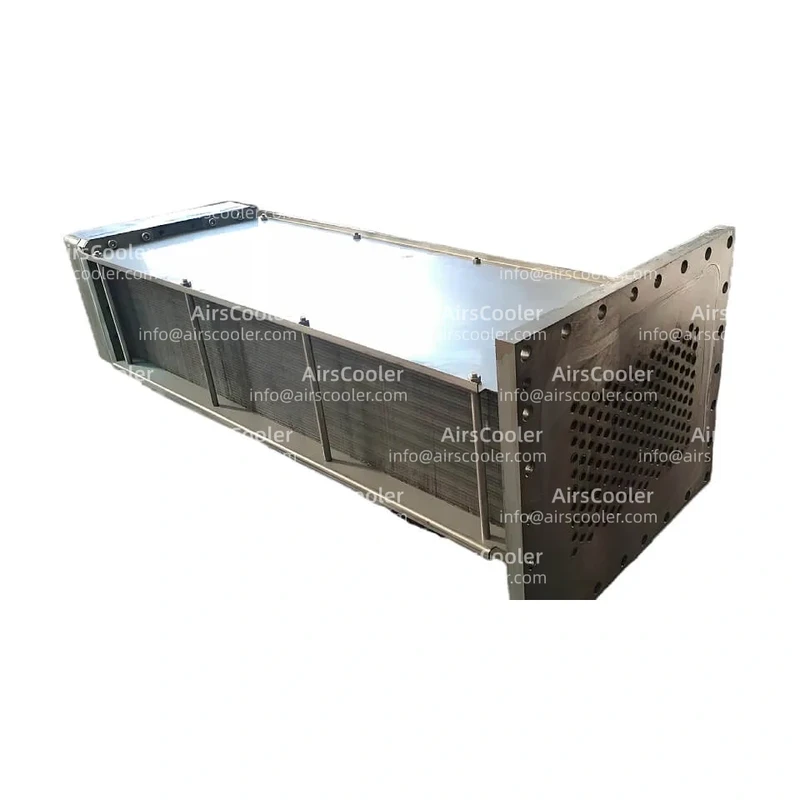

2.2 Structural Innovation Design

Horizontal Split Frame: The cooler body features a double-layer sealed structure with bolted upper and lower shell design, enabling complete maintenance without disassembling the compressor unit - only requiring removal of the gearbox cover.

Anti-Vibration Support system setup: Built-in 8 sets of special rubber shock absorbers combined with hydraulic balancing devices at the equipment base keep deformation within 0.02mm even under 1.5g vibration acceleration, fully meeting marine and seismic zone use case requirements.

Lightweight Composite Materials: Non-pressure modules use carbon fiber reinforced resin matrix composites, reducing cooler module weight by 28% compared to all-steel structures while meeting UL94 V-0 flame retardant standards.

2.3 operational performance Parameter Indicators

| Parameter Category | Specification Value | Test Conditions |

|---|---|---|

| Cooling Capacity | 185kW (full load condition) | Inlet air temperature 220℃ |

| Water Resistance Loss | ≤0.03MPa | Flow rate 28m³/h |

| Fouling Factor | 0.00018m²·℃/W | After 2000 hours continuous operation |

| Leakage Rate | ≤1×10⁻⁹Pa·m³/s | Helium mass spectrometer detection |

| Pressure Rating | 2.5MPa (water side)/1.6MPa (air side) | Hydraulic test |

| Temperature Range | -40℃ to +150℃ | Material limit test |

3. use case Scenarios and Typical Cases

3.1 Semiconductor Manufacturing

At TSMC's Fab18 facility, the TRE60 cooler system setup provides Class 0 oil-free compressed air for 12-inch wafer etching equipment. Through dual-redundant cooling circuits, the backup loop can automatically switch within 15 seconds during single system setup failure, ensuring continuous production. Actual operation data shows this system setup enhanced etching yield from 98.2% to 99.7%, saving over $12 million annually in downtime losses.

3.2 Deep Sea Oil & Gas Platforms

CNOOC's "Deep Sea No.1" energy station uses 6 TRE60 units to build a compressed air network. The specially anti-corrosion treated cooler modules keep ≤0.05mm annual corrosion rate in marine environments with salt spray concentration up to 5000mg/m³. Their modular design minimizes single cooler replacement time to 4 hours - 300% more efficient than traditional offerings.

3.3 Medical Cleanroom Engineering

Shanghai Ruijin Hospital's proton/heavy ion center uses the TRE60 system setup to provide ultra-clean compressed air for particle accelerators. The built-in 0.1μm air filters and dual-stage water separators help ensure output air oil content <0.003mg/m³, far exceeding ISO 8573-1 Class 0 standards, guaranteeing 10 years of fault-free operation for treatment equipment.

3.4 Extreme Environment use cases

Antarctic Zhongshan Station's research equipment uses a specially adapted TRE60 system setup. The cooler can operate normally in -89.2℃ ultra-low temperatures with antifreeze additives. Its electric heating insulation layer keep 5℃ startup temperature for cooling water system setups at -60℃, ensuring year-round operation of research equipment.

4. Maintenance Strategies

4.1 Daily Inspection Points

Water Quality Monitoring: Daily testing of cooling water pH (6.5-8.5), conductivity (<1500μS/cm) and chloride content (<50ppm). Corrosion inhibitors should be added periodically when using deionized water.

Pressure Monitoring: Weekly recording of cooling water inlet/outlet pressure difference. When difference >0.05MPa, backflushing or chemical cleaning is required.

Temperature Calibration: Monthly surface temperature distribution inspection using infrared thermal imagers. Abnormal hot spots may indicate heat exchange tube blockage.

4.2 Periodic Maintenance Procedures

Quarterly Maintenance:

- Disassemble cooler end covers, flush heat exchange tubes with high-pressure water gun (pressure ≤5MPa)

- Inspect titanium alloy tube surface corrosion, record maximum pitting depth

- Replace lubricating oil cooler filter element (5μm precision)

Annual Overhaul:

- Perform hydrostatic test (1.5× working pressure, hold for 30 minutes)

- Replace all O-rings (fluororubber material)

- Conduct magnetic particle inspection on cooler housing

4.3 Fault Diagnosis Guide

| Fault Symptom | Possible Cause | offering |

|---|---|---|

| Excessive exhaust temperature | Insufficient cooling water flow | Clean Y-filter, check water pump operation |

| Cooling water leakage | Aged sealing gasket | Replace high-temperature fluororubber gasket |

| Severe scaling | Excessive water hardness | Add compound phosphate antiscalant (5-10ppm concentration) |

| Excessive vibration | Shock absorber failure | Replace special rubber damping modules |

5. Conclusion: A Milestone in Centrifugal Compressor Cooling Technology

The Sullair Compressor Cooler TRE60 redefines industrial cooling system setup operational performance standards through deep integration of materials science, fluid dynamics, and intelligent manufacturing. Its innovative titanium alloy heat exchange matrix, intelligent temperature control algorithms, and modular design not only achieve industry-leading energy overall efficiency ratio (EER) of 4.8 but also minimize lifecycle maintenance costs by 35%.

In semiconductor, medical, energy and other fields with stringent compressed air quality requirements, the TRE60 cooler has become critical infrastructure for ensuring process stability. With the introduction of digital operation technology, this system setup will implement predictive maintenance through IoT modules in the future, providing more highly robust cooling offerings for compressed air systems in the Industry 4.0 era.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSullair Compressor Cooler TXZ165

View Details

View DetailsSullair Compressor InterCooler

View Details

View DetailsCooper Air Compressor Aftercooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.