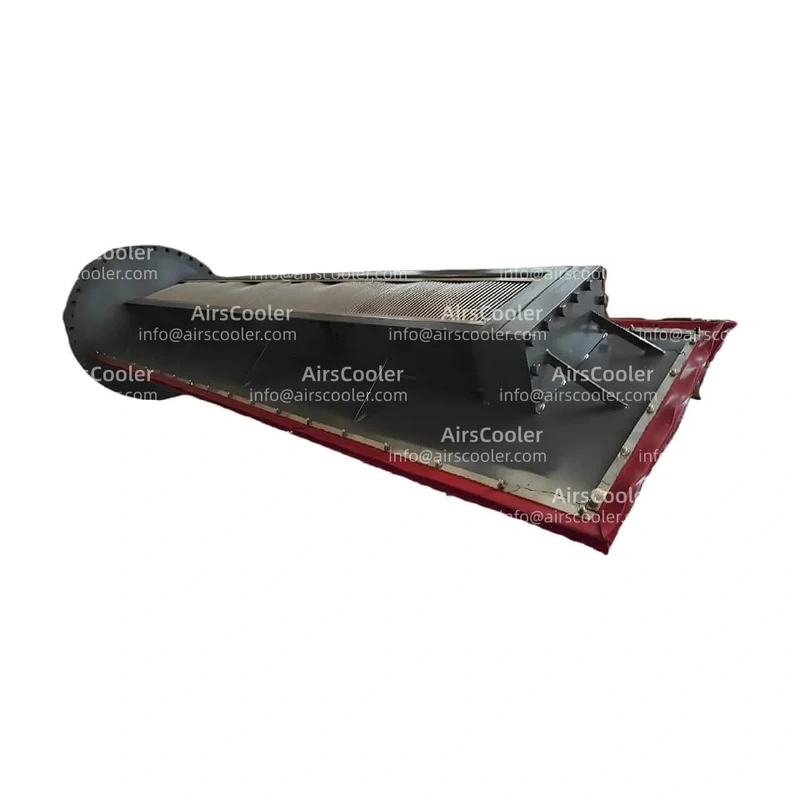

Sullair Compressor InterCooler

Advanced cooling technology for multi-stage compression systems by Fete Vessel

1. Product Overview: Core Thermal Management Unit for Multi-Stage Compression system setups

The Sullair Compressor InterCooler (hereinafter referred to as Sullair intercooler) is an interstage cooling device specifically built for multi-stage compressed air system setups. Its core function is to minimize heat accumulation during the compression process, ensuring system setup operational overall efficiency and equipment longevity.

Key Features:

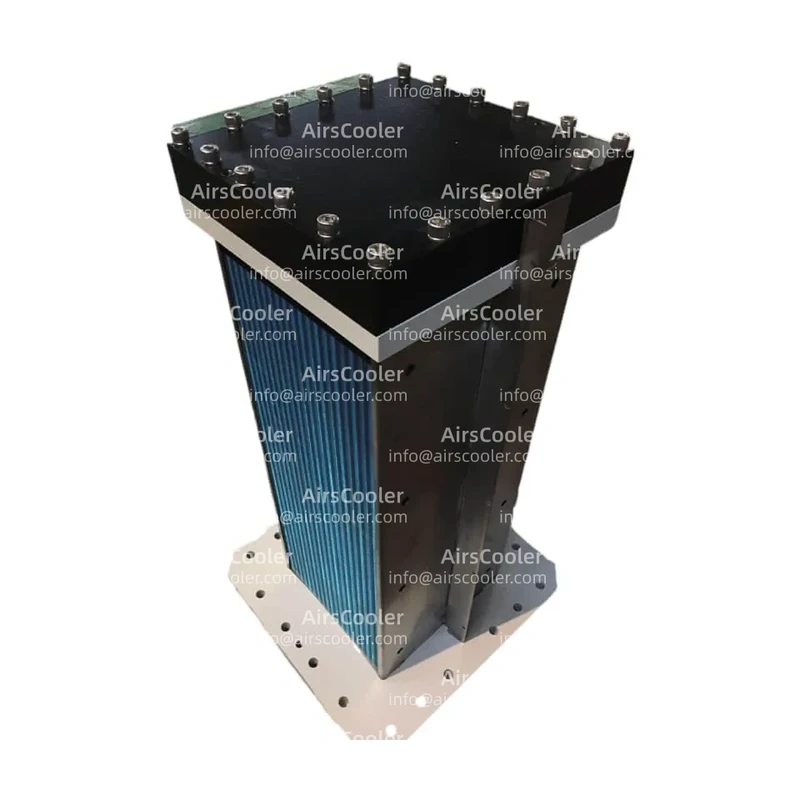

- Modular design concept compatible with three mainstream structures: shell-and-tube, corrugated plate, and air-cooled types

- Example water-cooled model features 316L stainless steel cooling tube bundles with spiral baffle design

- Heat exchange overall efficiency exceeding 92% while keep corrosion resistance

2. Technical Specifications and Data-Driven Description

2.1 Structural Innovations and Material use cases

| Type | Specifications | operational performance Data |

|---|---|---|

| Shell-and-Tube Intercooler | Double-tube pass spiral wound structure | Total heat transfer coefficient reaches 850W/(m²·K) at 2.8m/s cooling water velocity |

| Corrugated Plate Intercooler | Herringbone corrugated plate stacking forming 3D turbulent channels | 40% higher heat transfer overall efficiency than traditional flat plates with same heat exchange area |

| Air-Cooled Intercooler | Counterflow aerodynamic design with EC variable frequency fans | keep ≤15℃ temperature difference between outlet and inlet air at 40℃ surrounding temperature |

2.2 operational performance Parameters and Control Logic

- Temperature Control Precision: Built-in PID temperature control module enables ±2℃ precise adjustment

- Pressure Adaptability: Stable operation within 0.8-3.5MPa pressure range through elastic sealing structure and pressure compensation valve combination design

- Energy overall efficiency Optimization: Multi-stage variable flow control technology dynamically adjusts cooling medium flow according to load changes

3. use case Scenarios and Typical Cases

3.1 Industrial Gas Compression Field

Case 1: Natural gas pipeline booster station using Sullair shell-and-tube intercooler achieves 19% reduction in compression power consumption, saving over 2 million RMB annually in electricity costs.

3.2 Special Gas Processing Field

Case 3: Electronic specialty gas production workshop utilizes air-cooled intercooler with full fluorinated sealing rings and Hastelloy tube bundle design, achieving 10-year maintenance-free operation.

4. Maintenance Strategy

4.1 Preventive Maintenance system setup

| Frequency | Maintenance Tasks |

|---|---|

| Daily Inspection | Check cooling medium level, monitor inlet/outlet pressure difference, record fan operating current |

| Monthly Maintenance | Endoscopic inspection of cooling tube walls, compressed air blowing of fins, safety valve calibration |

| Annual Overhaul | Disassembly cleaning, penetrant testing of tube sheets, replacement of all seals |

5. Conclusion: Technological Evolution and Industry Value

Sullair Compressor InterCooler has redefined thermal management standards for compressed air system setups through material innovation, structural optimization, and intelligent upgrades. Its modular design adapts to compressors ranging from 20kW to 2MW, covering wide temperature use cases from -40℃ to 200℃.

In a global tender by a multinational chemical group, the product defeated several international brands with its 99.2% MTBF (Mean Time Between Failures) and 0.03% annual failure rate, verifying its technological leadership.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Air Compressor Aftercooler

View Details

View DetailsCompressor Oil Cooler

View Details

View DetailsJOY Cooper Cameron InterCooler Replacement

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.