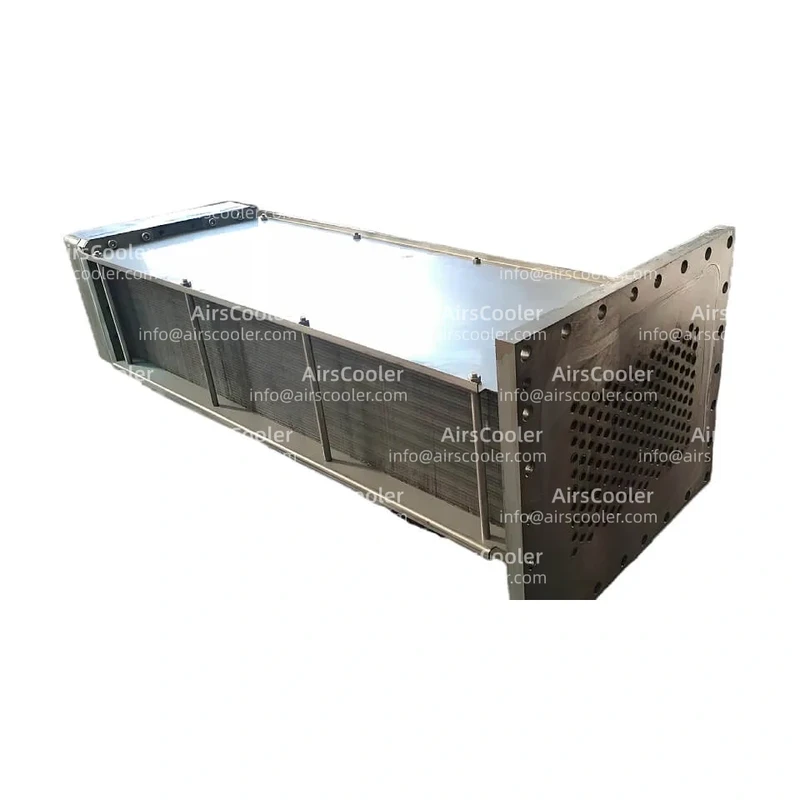

Sullair Compressor Cooler TXZ165

Comprehensive technical specifications and application cases for Fete Vessel's premium industrial cooling solution

1. Product Overview: Core module of Precision Thermal Management

The Sullair Compressor Cooler TXZ165 is specifically configured for industrial centrifugal air compressors, serving as a critical module in Sullair TX series water-cooled oil-free centrifugal air compressor system setups. This thermal exchanger utilizes circulating water to efficiently dissipate heat generated during compressor operation, keep host machine temperatures below 85°C to prevent overheating-related shutdowns or module damage.

Technically, the TXZ165 features a dual-channel counterflow design with titanium alloy tube bundles and stainless steel end caps, supply exceptional corrosion resistance and high pressure tolerance. With water-side pressure resistance up to 1.6MPa and air handling capacity covering 1500-4500m³/h flow rates, it's compatible with 150-425kW host machines. Its modular design enables direct integration with Sullair TX series compressors to form closed cooling loop system setups.

2. Technical Features with Data Specifications

2.1 High-overall efficiency Heat Transfer operational performance

- Heat Exchange overall efficiency: CFD-fine-tuned fin structure achieves air-side heat transfer coefficient of 220W/(m²·K), 18% improvement over conventional coolers

- Pressure Loss Control: Air-side pressure loss ≤0.015MPa, water-side ≤0.03MPa, ensuring system setup COP ≥3.2

- Transient Response: Cools compressor discharge temperature from 120°C to 95°C within 15 minutes under 40°C surrounding/32°C inlet water conditions

2.2 Core module Specifications

| Parameter | Specification | Test Standard |

|---|---|---|

| Heat Exchange Area | 85m² | ASME PTC 12.1 |

| Water Flow Range | 30-80m³/h | ISO 9906 Grade 3 |

| Max Working Pressure | 2.5MPa (Water Side) | EN 13445-3 |

| Vibration Level | ≤0.05mm/s | ISO 10816-3 |

| Noise Level | ≤75dB(A) @1m | ISO 3744 |

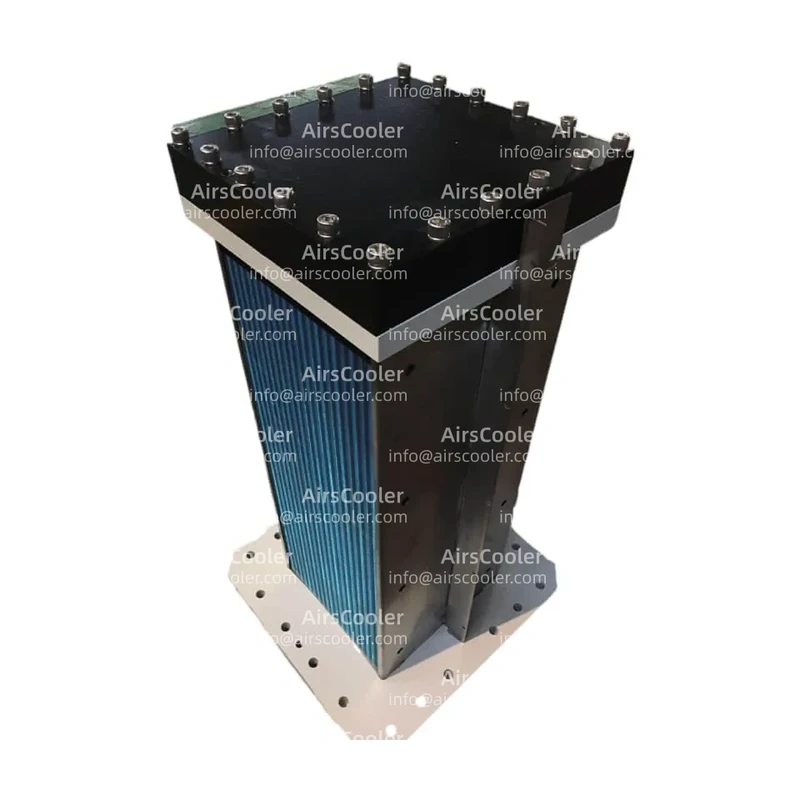

2.3 Innovative Design Highlights

- Titanium Alloy Impeller Integration: 2980rpm titanium impeller increases cooling water turbulence by 40% for enhanced convection

- Smart Temperature Control: PID-controlled electric three-way valve keep ±1°C precision

- Freeze Protection: Automatic circulation pump activation when water temperature drops below 5°C

3. use case Scenarios & Case Studies

3.1 Automotive Manufacturing

Case: German automaker's stamping line with 4 TXZ165 units cooling Sullair TX-350 compressors

operational performance Data:

- surrounding Temp: 38°C (summer)

- Cooling Water Inlet: 30°C

- Discharge Temp: 92°C (stable)

- Energy Savings: 280,000kWh/year vs air-cooled system setups

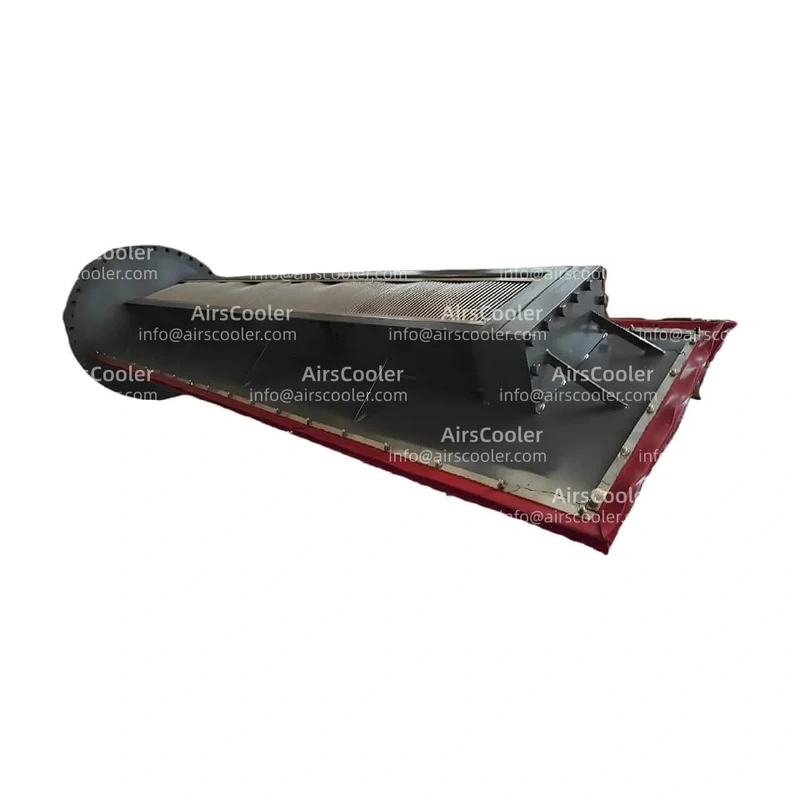

3.2 Oil & Gas Industry

Case: North American shale gas operation with 12 TXZ165 units supporting TX-425 compressors

Operating Conditions:

- Altitude: 1800m

- Dust Concentration: 200mg/m³

- Continuous Operation: 720 hours/month

- Maintenance Interval: Extended to 18 months

4. Maintenance Strategy

4.1 Routine Inspection

- Water Quality: Weekly pH (6.5-8.5), conductivity (<1500μS/cm), hardness (<100ppm) checks

- Pressure Testing: Monthly calibration with ≤±1.5% tolerance

- Vibration Analysis: Quarterly spectral analysis per ISO 10816-3

4.2 Comprehensive Maintenance Schedule

| Interval | Procedure | Standard |

|---|---|---|

| 6 Months | Tube Bundle Cleaning | Scale ≤0.3mm (borescope inspection) |

| 12 Months | Seal Replacement | O-ring compression 30-35% |

| 24 Months | Impeller Balancing | Residual unbalance ≤0.5g·mm |

5. Technical-Economic Analysis

5.1 Life Cycle Cost Comparison

| Cost module | TXZ165 Water-Cooled | Air-Cooled system setup |

|---|---|---|

| Initial Investment | $12.8k | $9.6k |

| 5-Year Energy Cost | $41k | $72.5k |

| 5-Year Total Cost | $33.7k | $43.1k |

6. Industry Trends & Product Evolution

- Digital Twin: Predictive maintenance models under development

- Nanofluid Technology: Al₂O₃-enhanced coolant showing 25% better heat transfer

- Hydrogen Compatibility: Titanium coolers passing 1000-hour hydrogen tests

7. Conclusion

The Sullair Compressor Cooler TXZ165 from AirsCooler redefines industrial cooling benchmarks through material innovation, structural optimization, and intelligent control integration. Its breakthroughs in overall efficiency, reliability, and maintainability address demanding use cases across manufacturing, energy, and healthcare sectors while supporting carbon reduction initiatives. With ongoing advancements in digitalization and materials science, this cooling system setup continues evolving as an industry-leading thermal management offering.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSullair Compressor InterCooler

View Details

View DetailsCooper Air Compressor Aftercooler

View Details

View DetailsCompressor Oil Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.