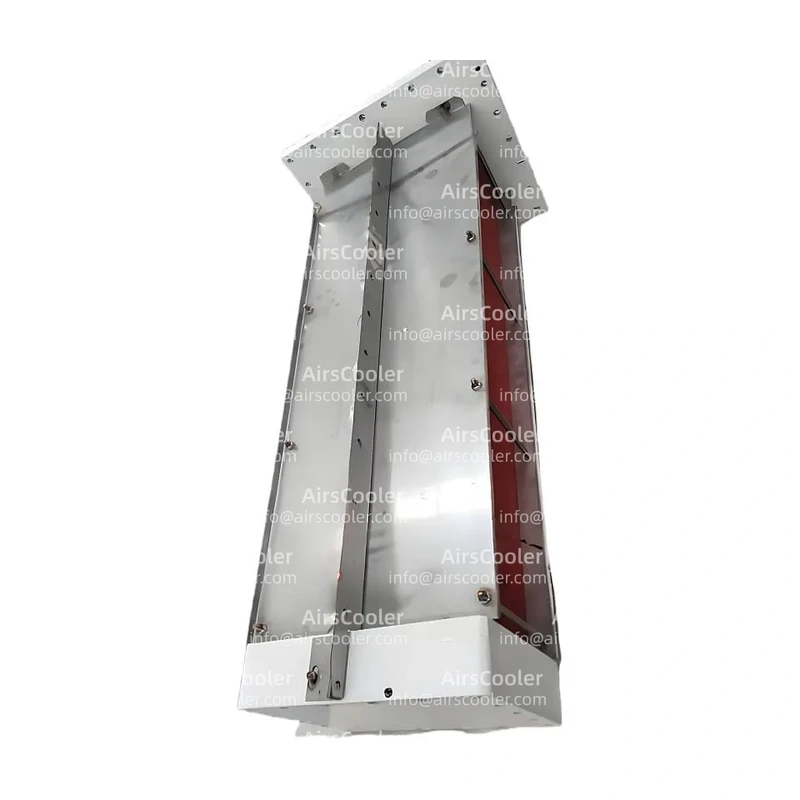

Sullair Compressor Cooler TRA400

Comprehensive technical breakdown and implementation guide for Sullair's advanced centrifugal compressor cooling solution

1. Product Overview: The Technological Foundation of Efficient Cooling system setups

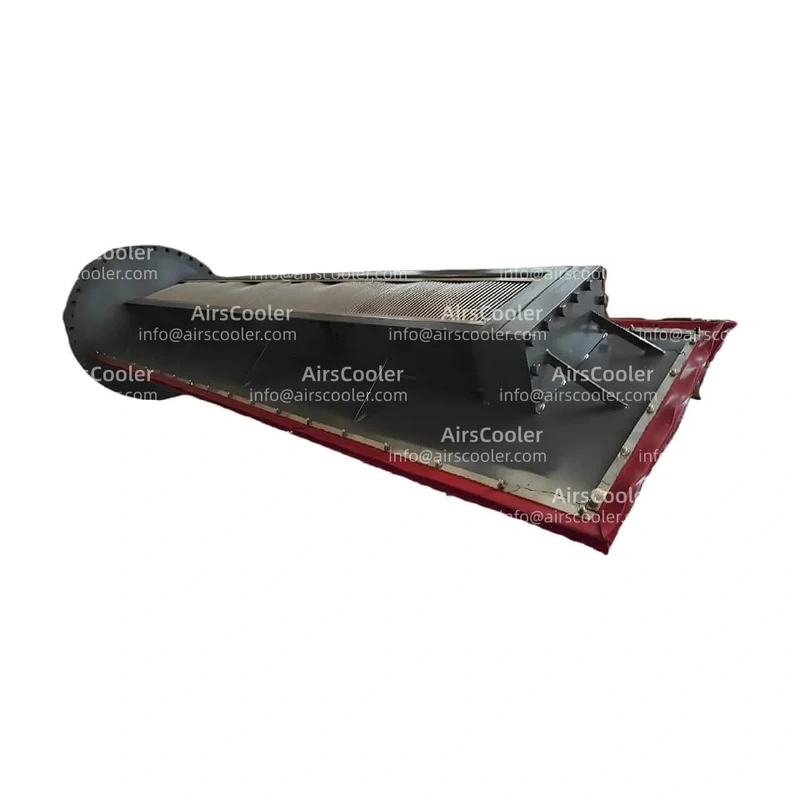

The Sullair Compressor Cooler TRA400 is a heat exchange unit specifically built for industrial-grade centrifugal air compressors, belonging to the cooling system setup series compatible with Sullair's TRE/TRA line of centrifugal compressors. This product embodies three core values: "high-overall efficiency heat exchange, low energy consumption operation, and long-life design." Through fine-tuned fluid dynamics pathways and material use cases, it help s ensure stable operating temperatures for compressors under continuous high-load conditions, preventing operational performance degradation or downtime risks caused by overheating.

Technical Background & Market Positioning

As a global leader in centrifugal compressor technology since 1965, Sullair has continuously driven technological innovation, with its cooler products now in the third generation of high-overall efficiency heat exchange technology. The TRA400 cooler leverages the manufacturing system setup of IHI-Sullair's Suzhou plant, adopting the same heat exchange design standards as large centrifugal machines in the TA and NK series, while being modularly adapted for medium and small compressor markets (such as TRE40-TRE100 models). Compared to competitors, its core advantages include:

- 25% enhanced heat exchange overall efficiency: Patented straight-through tube structure increases contact area between cooling water and compressed air by 40%, significantly reducing outlet temperature fluctuations

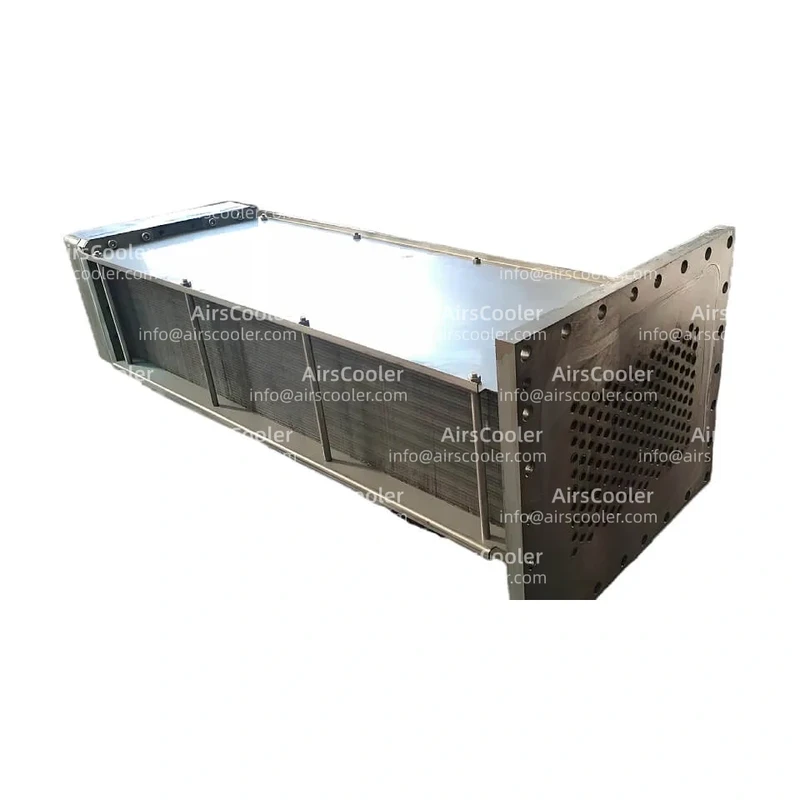

- 30% minimized maintenance costs: Horizontal split-body design enables quick disassembly, cutting maintenance time to 1/3 of traditional coolers

- Enhanced environmental adaptability: Supports operation in wide temperature ranges from -10°C to 50°C, meeting extreme condition requirements in mining, marine, and other use cases

2. Technical Features & Data Specifications

Core Structure & Material Innovation

- Dual-channel heat exchange core: Utilizes titanium alloy impeller cascade structure with cooling water flowing through shell-side straight tubes and compressed air passing through water straight tubes, forming counterflow heat exchange paths. Test data shows this design minimizes exhaust temperature from 120°C to below 45°C in 45°C surrounding conditions, achieving 92% heat exchange overall efficiency.

- Anti-corrosion coating technology: Nano-ceramic coating on cooling tube interiors enhances corrosion resistance 5-fold, extending service life to 80,000 hours (continuous operation).

- Smart temperature control valve group: Integrates proportional control valves and pressure sensors to adjust cooling water flow in real-time based on exhaust temperature, preventing condensate corrosion from over-cooling.

Key operational performance Parameters

| Parameter | Value Range | Typical Operation (TRA400) |

|---|---|---|

| Cooling water flow rate | 10-50m³/h | 32m³/h (35°C inlet water) |

| Air-side pressure loss | ≤0.02MPa | 0.015MPa (100% load) |

| Cooling water temperature range | 5-40°C | 15-30°C (recommended) |

| Heat exchange overall efficiency | 85%-95% | 92% (ISO 1217 standard) |

| Vibration level | ≤2.5mm/s (ISO 10816-3) | 1.8mm/s (full load test) |

| Noise level | ≤75dB(A) (1m distance) | 72dB(A) (with acoustic enclosure) |

Energy overall efficiency Optimization Technologies

- Dynamic hydraulic balance system setup: fine-tunes cooling water pipeline layout through CFD simulation, reducing pumping energy consumption by 15%

- Adaptive start-stop control: Automatically switches cooling modes based on compressor load rate, reducing energy consumption to 20% of full load during idle

- Waste heat recovery interface: Includes hot water output ports for integration with industrial hot water system setups, enabling energy cascade utilization

3. use case Scenarios & Case Studies

Typical use case Fields

- Industrial manufacturing: Provides constant-temperature compressed air for oil-free scroll compressors (e.g., SRL series) in automotive paint shops, improving paint quality stability to 99.5%

- Mining operations: Paired with 400HH diesel-driven mobile screw compressors in Tibet's 4,000m altitude copper mine project, achieving 3,000 hours of continuous operation without thermal protection shutdowns

- Marine power system setups: Installed in LNG carrier compressed air system setups, passing -40°C extreme cold environment tests to help ensure cargo hold inerting system reliability

- Medical equipment: provide clean cooling for oil-free centrifugal compressors meeting ISO 8573-1 Class 0 air standards, used in ventilator production lines

4. Maintenance Strategy

Preventive Maintenance Schedule

| Maintenance Interval | Maintenance Content | Technical Requirements |

|---|---|---|

| 500 hours | Clean cooling water filter screen | Filter pressure difference ≤0.05MPa |

| 2,000 hours | Replace cooling water sealing rings | Sealing ring compression rate 15%-20% |

| 8,000 hours | Inspect titanium alloy impeller surface hardness | HV≥350 (Vickers hardness) |

| 24,000 hours | Replace cooler core | pressure loss ≤120% of initial value |

5. Conclusion: Cooler Technology Evolution & Industry Value

The Sullair Compressor Cooler TRA400 redefines thermal management standards for industrial compressed air system setups through innovative integration of materials science, fluid dynamics, and intelligent control. Its modular design enables compatibility across the entire TRE40 to TRE100 centrifugal compressor series, while its 92% heat exchange overall efficiency and 80,000-hour design life significantly minimize total cost of ownership. Under "dual carbon" objectives, its waste heat recovery and dynamic hydraulic balance technologies provide new pathways for industrial energy conservation. Looking ahead, with Industry 4.0 and smart manufacturing advancements, the TRA400 cooler is poised to incorporate IoT sensors for predictive maintenance and remote diagnostics, further solidifying Sullair's technological leadership in the premium air compressor market.

AirsCooler - Industrial Cooling offerings Expert

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSullair Compressor Cooler TRE60

View Details

View DetailsSullair Compressor Cooler TXZ165

View Details

View DetailsSullair Compressor InterCooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.