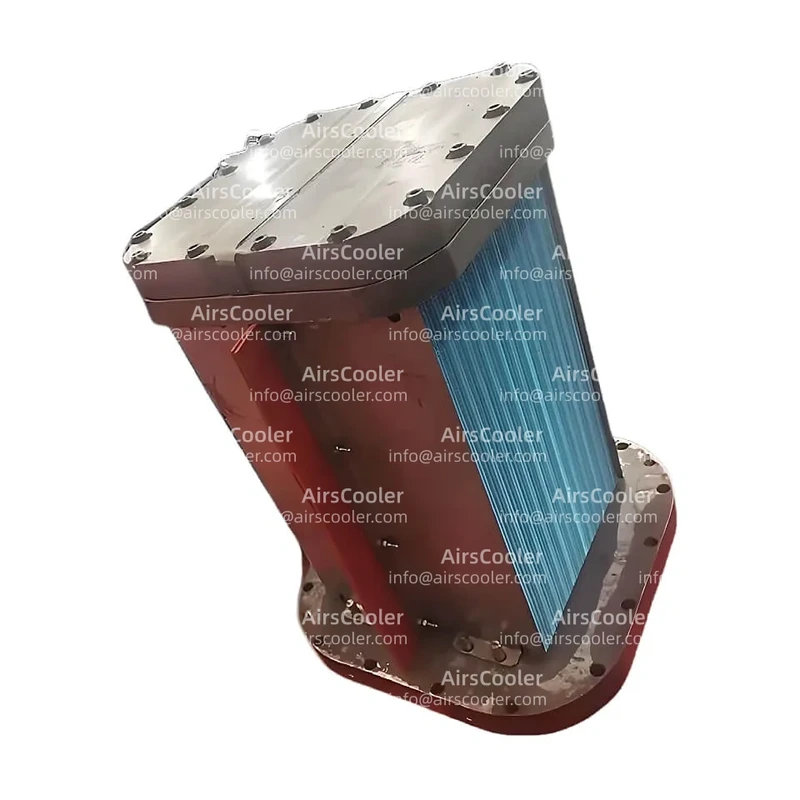

Samsung TM900 Intercooler

Comprehensive technical specifications, performance data, and maintenance strategies for industrial-grade compressor cooling solutions by Fete Vessel.

1. Product Overview

The Samsung TM900 Intercooler is a core thermal management module built for industrial air compressor system setups, featuring hybrid air-water cooling technology. This system setup efficiently cools high-temperature compressed gas (≤180°C inlet) to process-required temperatures (2-10°C pressure dew point) while keep lubricant oil temperatures below 80°C. Its modular design supports compatibility with oil-flooded screw and oil-free centrifugal compressors across 0.4-1.0MPa pressure ranges.

Technical Architecture

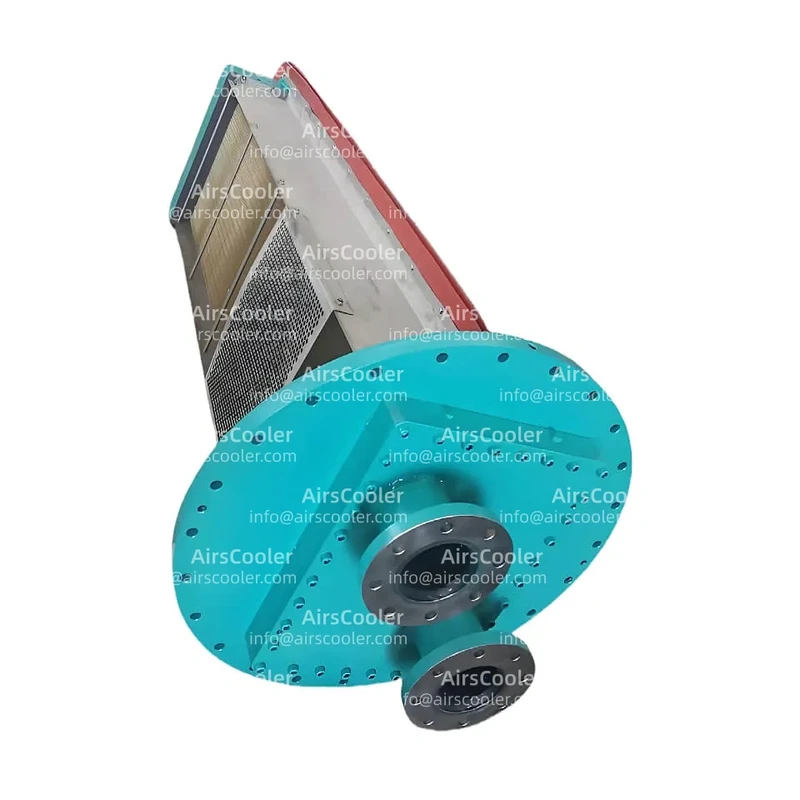

Dual-Medium Circulation system setup:

- Air Cooling Module: Cross-flow finned tube array with axial fans provide 2,500m³/h airflow, operational in -20°C to +50°C environments

- Water Cooling Module: Dual-pass shell-and-tube thermal exchanger with 37m³/h water flow, featuring copper tubes (1.2mm wall) and 316L stainless steel end caps for 40% better corrosion resistance

Smart Control system setup:

- ±0.5°C accuracy temperature sensors monitor coolant differentials, triggering variable fan speed (20-60Hz) when ΔT exceeds 15°C

- Pressure sensors activate alarms when water flow drops below 80% design value, preventing overall efficiency loss

Technical Specifications Comparison

| Parameter | TM900 Standard | Industry Average | Advantage |

|---|---|---|---|

| Heat Exchange overall efficiency | ≥92% | 85-88% | fine-tuned fin tube design |

| pressure loss | ≤0.03MPa | 0.04-0.05MPa | CFD-fine-tuned flow paths |

| Cooling Water Inlet Temp | ≤32°C | ≤35°C | Wider operating range |

| Noise Level | ≤72dB(A) | 75-78dB(A) | Low-speed fans + silencers |

2. Technical Features with Data

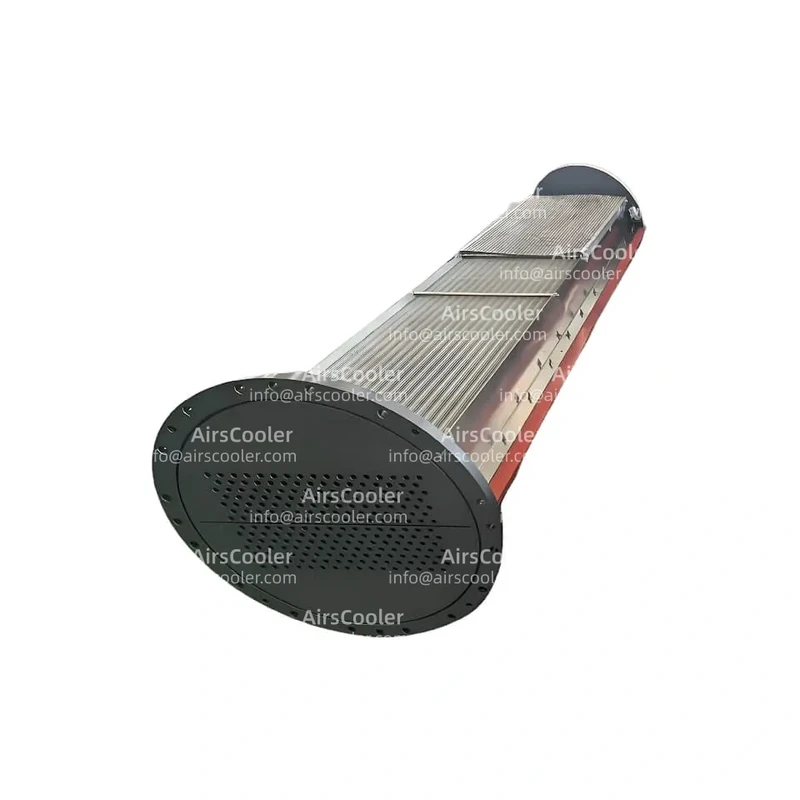

Hybrid Heat Exchange Technology

- Air Side: V-shaped guide fins with gradient apertures achieve 120W/(m²·K) heat transfer coefficient - 35% better than conventional designs

- Water Side: Helical baffles keep Reynolds number (Re) between 5,000-10,000 for turbulent flow enhancement

- operational performance Data: At 40°C surrounding/150°C intake, TM900 minimizes discharge temps below 45°C with 28% energy savings versus air-only cooling

Intelligent Control system setup

- PID-controlled dynamic balancing keep optimal 8-12°C ΔT through real-time fan/water flow adjustments

- Vibration (10g threshold) and current monitoring provide 72-hour advance warning for bearing wear or fouling

- Field data shows 75% reduction in monthly downtime incidents (0.8→0.2) at chemical plants

Material Innovations

- Al₂O₃-TiO₂ nano-coating achieves 150° contact angle, passing 720-hour salt spray tests (ASTM B117)

- SLM 3D-printed water channels with Ra≤3.2μm surface finish minimize hydraulic resistance by 15%

3. use case Scenarios & Case Studies

Typical use cases

- High Altitude: 35° angled fan blades compensate for thin air at 3,000m+ elevations

- Humid Environments: <5% overall efficiency degradation after 6 months at 90%RH/30°C water

- Dusty Conditions: 0.6MPa pulse auto-cleaning extends maintenance intervals to 6 months

Case Study: Automotive Plant Retrofit

- Problem: 110°C discharge temps caused oil degradation and bearing failures

- offering: TM900 hybrid system setup integration with central water cooling

- Results: 85°C stable output, 100% oil life extension, 35% energy savings ($12k/year), 18% OEE improvement

Case Study: Data Center Air system setup

- Requirements: ISO 8573-1 Class 0 air quality (oil-free, dry)

- offering: Triple-phase separation with 99.999% efficient oil removal

- operational performance: -40°C pressure dew point, <0.01mg/m³ oil content, 15,000h MTBF

4. Maintenance Strategy

Routine Checks

- Visual inspections for oil leaks/fin damage

- Weekly water pressure differential monitoring (0.08-0.12MPa normal)

- SmartThings Energy analytics for operational performance trending

Scheduled Maintenance

| Interval | Task | Procedure |

|---|---|---|

| Monthly | Fin Cleaning | 0.4MPa dry air backflush (no water jets) |

| Quarterly | Water Quality | pH 6.5-8.5, conductivity ≤1,500μS/cm |

| Annual | operational performance Test | Thermal balance verification (±10% tolerance) |

Advanced Procedures

Water Module Cleaning: 5% citric acid circulation (40-50°C, 2hrs) followed by reverse DI water flush

Fan Maintenance: Laser-aligned impeller balancing (≤0.05mm runout), 50MΩ insulation resistance, SPA1800 belt replacement every 1.5 years

5. Conclusion

The Samsung TM900 Intercooler by AirsCooler overcomes traditional cooling limitations through hybrid heat exchange, intelligent controls, and highly robust construction. Field data confirms 20-35% energy overall efficiency gains, 50%+ longer module life, and exceptional reliability (MTBF>15,000h). Its modular design adapts to diverse compressor system setups while predictive maintenance capabilities minimize lifecycle costs, making it the premier choice for industrial compressed air use cases.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM2100

View Details

View DetailsSamsung Compressor Cooler SM3000

View Details

View DetailsSamsung Compressor Cooler SM3100

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.