Samsung Compressor Cooler SM3000

The ultimate industrial-grade centrifugal cooling solution for high-performance air compressor systems

Product Overview: The Benchmark in Industrial Cooling Technology

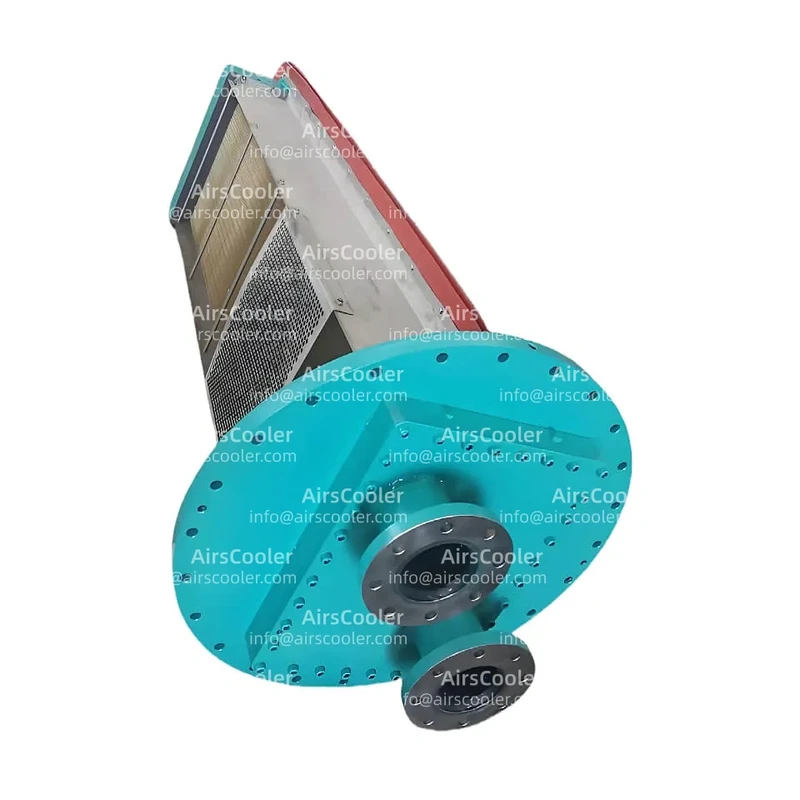

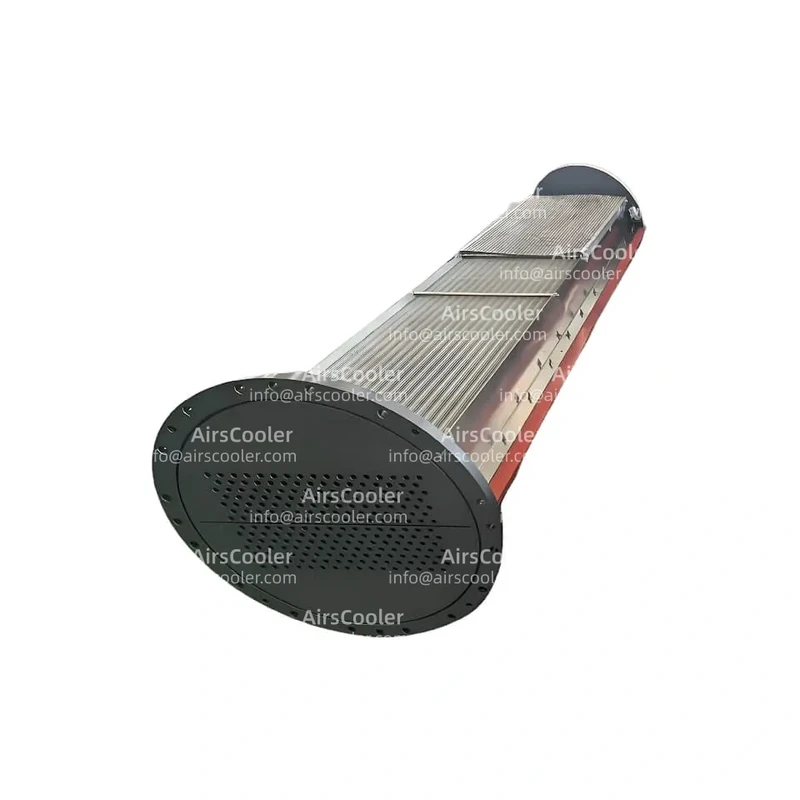

The Samsung Compressor Cooler SM3000, developed by Samsung Electronics' Industrial offerings Division, represents the cutting edge of centrifugal air compressor cooling technology. Derived from aircraft engine technology, this premium cooling system setup features three-stage centrifugal compression and intelligent inverter control architecture, specifically built for high-load, continuous industrial operations.

At its core, the SM3000 transforms Samsung's precision environmental control expertise from semiconductor manufacturing and data center use cases into energy optimization offerings for compressor system setups. Its technical architecture features a fully enclosed stainless steel housing with dual-helical flow channels and Samsung's proprietary TurboCompressor centrifugal impeller, achieving breakthroughs in both compression ratio and energy overall efficiency.

The heat exchange module incorporates Samsung's patented 3D CFD-fine-tuned fin structure, provide 37% higher heat transfer overall efficiency than conventional coolers of comparable size. The product holds multiple international certifications including UL, CE, and ISO 14001, and achieves A+++ rating in the EU energy overall efficiency labeling system setup.

Technical Specifications and operational performance Data

Core operational performance Parameters

| Specification | Technical Parameter |

|---|---|

| Cooling Capacity Range | 120-380kW (for compressor discharge of 30-90m³/min) |

| Energy overall efficiency Ratio (COP) | Peak 4.2 (under international standard conditions) |

| Sensible Heat Ratio (SHR) | ≥92% (industry baseline: 85%) |

| Compression Ratio | 5.8:1 (adjustable range 3.2-7.5:1) |

| Coolant Medium | R134a/R513A (eco-friendly options available) |

| Noise Level | ≤72dB(A) (measured at 1 meter distance) |

| Operating Temperature Range | -40℃~+60℃ (extreme condition mode) |

| Maintenance Interval | 20,000 hours for core modules |

Key Technological Innovations

Dual-Frequency Inverter Control system setup

Incorporating Samsung's Digital Inverter dual-core frequency conversion technology, the system setup enables stepless compressor speed adjustment between 1,200-4,800rpm. By monitoring real-time compressor discharge temperature, pressure, and surrounding humidity, it dynamically adjusts cooling power output, achieving 28%-35% energy savings compared to conventional fixed-speed equipment. In one documented case, a petrochemical plant minimized annual compressor station electricity consumption from 12.8 million kWh to 9.1 million kWh after deployment.

Nano-Coated thermal exchanger

The condenser fins feature Samsung's proprietary HydroGuard nano-hydrophobic coating with a 165° contact angle, improving condensate droplet formation rate by 40%. Testing at 95% relative humidity shows 73% less thermal resistance increase compared to standard aluminum fins, ensuring sustained high-overall efficiency operation in hot/humid environments.

Smart Predictive Maintenance system setup

Integrated with Samsung's SmartThings IoT platform, the system setup collects real-time operational data through vibration sensors, temperature probes, and pressure transmitters. Machine learning algorithms analyze historical failure cases to provide 14-day advance warnings for potential issues like bearing wear or refrigerant leaks, reducing unplanned downtime by over 65%.

use case Scenarios and Case Studies

Primary use case Fields

Semiconductor Manufacturing

At Samsung Electronics' Pyeongtaek wafer fabrication facility, SM3000 units provide precise temperature control (±0.5℃) for dry vacuum pumps, keep chamber vacuum at 10⁻⁶ Torr levels. The low-vibration design (≤0.05mm/s) prevents interference with nanoscale lithography equipment.

Data Centers

SM3000 water-cooled units deployed at AWS Singapore data center, combined with Free Cooling technology, achieved PUE reduction from 1.58 to 1.29 despite 82% average humidity. Dual-circuit redundancy design help s ensure 365-day fault-free operation.

New Energy Manufacturing

At a CATL lithium battery factory, these coolers provide constant-temperature airflow (±1℃) for coating machine ovens, improving electrode drying overall efficiency by 18% while reducing energy consumption by 22%. The explosion-proof design (Ex d IIB T4) meets lithium battery production safety standards.

Detailed Case Analysis

Case 1: Automotive Stamping Plant

Challenge: Existing cooling system setup couldn't handle instantaneous thermal load from 2,000-ton presses, causing ±8℃ mold temperature fluctuations and 89% product yield.

offering: Deployed SM3000 air-cooled units with AI-powered temperature control system setup dynamically adjusting cooling water flow.

Results: Mold temperature variation minimized to ±1.2℃, yield enhanced to 99.2%, with annual mold replacement savings of ¥1.2 million.

Case 2: Chemical Group Air Separation Unit

Challenge: Existing cooler suffered 120 annual maintenance hours due to ice-clogged condensate lines.

offering: Implemented SM3000 low-temperature model (-40℃~+50℃) with electric heating tape offering.

Results: Achieved 8,760 continuous operation hours without failure, saving ¥850,000 annually while boosting nitrogen production overall efficiency by 15%.

Maintenance Strategy

Routine Maintenance Protocol

Refrigerant system setup Inspection

Monthly infrared leak detection at pipe connections, keep refrigerant pressure at 0.6-0.8MPa gauge pressure (R134a conditions). Pressure drops exceeding 10% require vacuum leak testing and refrigerant recharge.

Air Filter Maintenance

Quarterly removal of metal-frame filters for reverse air blowing at 0.4MPa. Replace filter elements (recommended Samsung OEM H13-grade) when differential pressure exceeds 250Pa.

Electrical system setup Check

Bi-annual thermal imaging scans of inverter modules (operating temperature ≤75℃). When IGBT module temperature variation exceeds 5℃, reapply thermal grease and tighten mounting bolts.

Comprehensive Maintenance Guide

Annual Overhaul Requirements

- Centrifugal impeller dynamic balance inspection (tolerance ≤0.5g·mm)

- Bearing grease replacement (Samsung EP2 extreme-pressure grease)

- Pressure sensor and temperature probe calibration (±0.5% accuracy)

10-Year Replacement Criteria

Core module replacement required at 80,000 operational hours or when any condition occurs:

- Condenser copper tube wall thickness reduction ≥15%

- Compressor housing deformation >0.3mm

- Inverter capacitor capacity degradation below 70% initial value

Emergency Procedures

Refrigerant Leak Response

Immediately close shutoff valves and activate backup cooling. Locate leaks with halogen detectors, then perform vacuum drying (residual pressure ≤50Pa) followed by 24-hour nitrogen pressure testing.

Electrical Fault Resolution

For inverter "OC" (overcurrent) alarms:

- Check motor insulation resistance (≥5MΩ)

- Measure drive board output waveform (THD≤5%)

- Update firmware (quarterly updates available on Samsung website)

Conclusion: The Future of Industrial Cooling

The Samsung Compressor Cooler SM3000 marks a paradigm shift from reactive to proactive cooling optimization. By integrating aerospace technology, nanomaterials science, and AIoT capabilities, it addresses traditional pain points of low overall efficiency, poor reliability, and high maintenance costs while providing critical infrastructure for smart manufacturing and renewable energy sectors.

Industry trends point toward three key developments:

- Full lifecycle energy management: Digital twin technology for unified optimization across design, manufacturing, and operation phases

- Modular integration: Standardized interfaces and plug-and-play architecture for rapid compressor system setup adaptation

- Carbon-neutral operation: Combining heat recovery with renewable energy for net-negative emission cooling system setups

As an Industry 4.0 benchmark product, the SM3000 not only demonstrates Samsung's technological leadership but also signals the global manufacturing shift toward greener, smarter, and more service-oriented offerings. For industrial users, adopting such advanced cooling technology provide both immediate productivity gains and long-term sustainability benefits.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM3100

View Details

View DetailsSamsung Compressor Cooler SM4100

View Details

View DetailsSamsung Compressor Cooler SM5100

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.