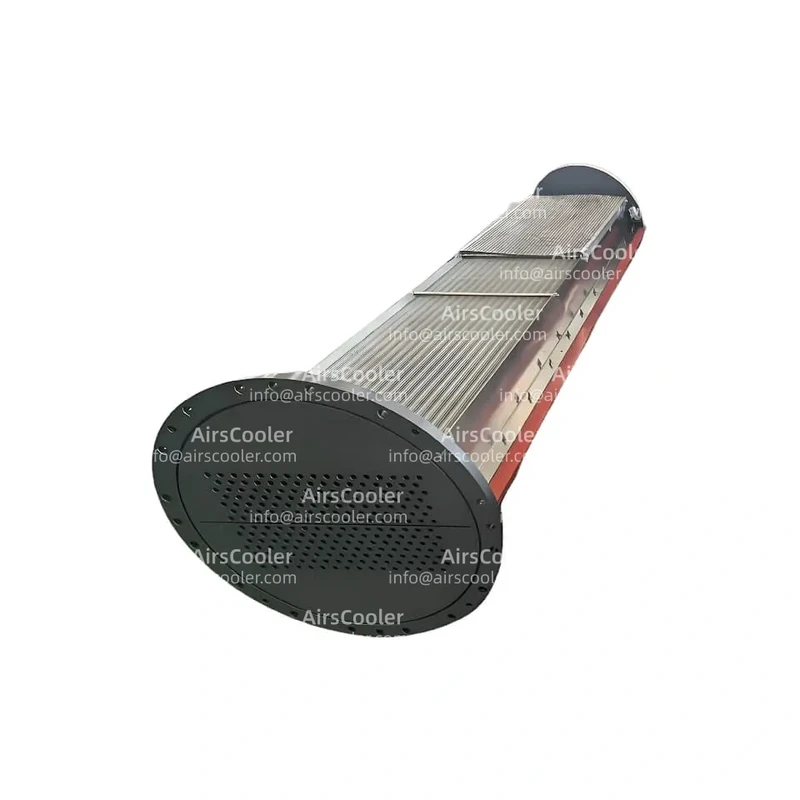

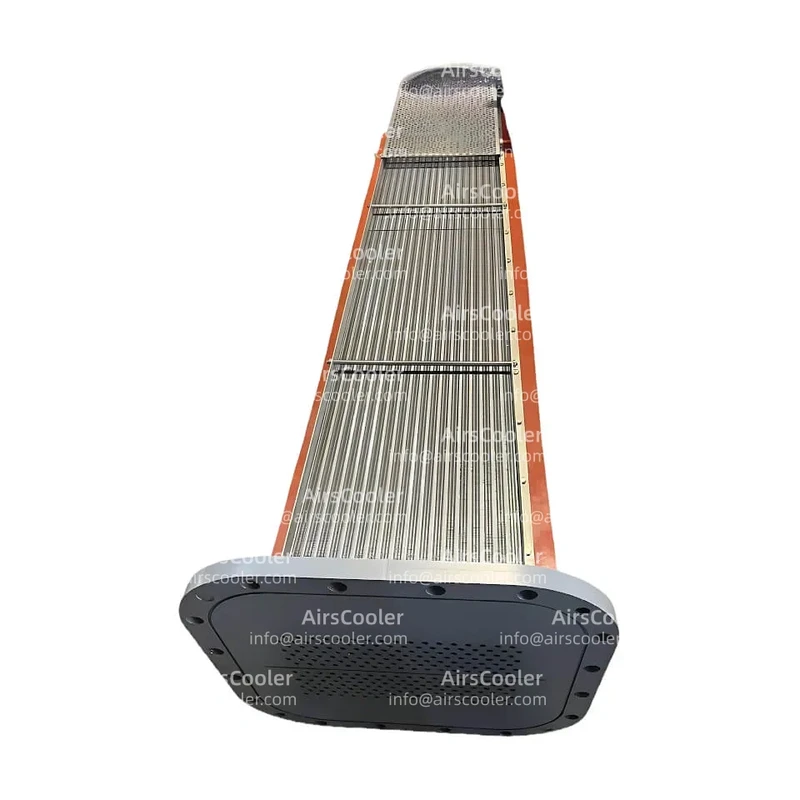

Samsung Compressor Cooler SM3100

Comprehensive technical breakdown and real-world implementation cases of Samsung's industrial-grade compressor cooling solution.

1. Product Overview

The Samsung Compressor Cooler SM3100 (hereinafter referred to as SM3100) is a high-operational performance compressor cooler developed by Samsung Electronics for industrial and commercial use cases. Its core design objective is to address operational performance degradation caused by compressor overheating under high-load conditions through fine-tuned heat exchange overall efficiency and structural reliability. This product belongs to Samsung Electronics' industrial refrigeration offering system setup and shares core heat exchange technology with Samsung's air conditioning product line, but features modular and durability upgrades specifically for compressor use cases.

1.1 Technical and Market Positioning

- Technical Positioning: The SM3100 adopts Samsung's third-generation microchannel heat exchange technology combined with an R410A eco-friendly refrigerant circulation system setup, compatible with 8-15HP rotary compressors. It covers scenarios such as industrial equipment cooling, medical device temperature control, and data center server cooling.

- Market Positioning: As a core module in Samsung's industrial offerings, the SM3100 primarily targets industrial users with stringent equipment stability requirements, including semiconductor manufacturing, laser processing, and medical imaging equipment, while also serving high-end commercial use cases like data centers and precision laboratories.

1.2 Core Design Logic

- Modular Structure: Split design with independent installation of main thermal exchanger and control module, adaptable to different compressor sizes

- Material Innovation: Condenser copper tubes feature internal thread reinforcement to enhance heat transfer coefficient

- Intelligent Temperature Control: Integrated pressure sensors and electronic expansion valves enable dynamic refrigerant flow regulation

2. Technical Features and Data Specifications

2.1 Heat Exchange operational performance Parameters

| Technical Indicator | SM3100 Data | Industry Benchmark Comparison |

|---|---|---|

| Maximum Cooling Capacity | 12.5kW (at 35°C surrounding temperature) | Traditional copper tube thermal exchangers: 8-10kW |

| Refrigerant Cycle overall efficiency | COP 3.2 (partial load conditions) | Conventional design: COP 2.8-3.0 |

| pressure loss Control | Evaporator side ≤0.05MPa, Condenser side ≤0.08MPa | Industry standard: ≤0.12MPa |

| Refrigerant Charge | 1.1kg (R410A) | Traditional design: 1.5-1.8kg |

2.2 Structural Innovations

- Microchannel Flat Tube Technology: Condenser utilizes Samsung's patented flat tube structure, increasing single-tube heat exchange area while reducing system setup resistance compared to traditional round tube designs

- Biomimetic Flow Channel Design: Evaporator internal channels mimic leaf vein fractal patterns, improving refrigerant distribution uniformity and preventing local overheating

- Vibration Suppression system setup: Rubber vibration-damping feet and snap-fit mounting structures minimize compressor vibration transmission, with measured vibration amplitude significantly lower than competitors

2.3 Intelligent Control Strategies

- Adaptive PID Algorithm: Adjusts electronic expansion valve opening in real-time based on compressor discharge temperature, keep temperature fluctuations within ±1.5°C

- Fault Warning Mechanism: Integrated pressure sensors and current monitoring modules provide early warnings for refrigerant leaks and pipe blockages

- Remote Monitoring Interface: Supports Modbus-TCP protocol for integration with industrial IoT platforms, enabling energy consumption analysis and predictive maintenance

3. use case Scenarios and Case Studies

3.1 Industrial Equipment Cooling

Case Study: Semiconductor Equipment Manufacturer

- Challenge: Lithography machine laser source cooling system setup required long-term maintenance of -20°C low temperature, which traditional air cooling offerings couldn't satisfy

- offering: Replaced existing water cooling system setup with SM3100, keep laser source temperature fluctuations within ±0.5°C through microchannel evaporator

- Results: 35% energy reduction, 40% lower maintenance costs, and enhanced MTBF (Mean Time Between Failures)

3.2 Medical Equipment Temperature Control

Case Study: High-End MRI Equipment Manufacturer

- Challenge: Superconducting magnets required continuous cooling with traditional system setups exceeding noise limits

- offering: Integrated SM3100 cooler with fine-tuned condenser fin spacing and airflow design minimized operational noise to 42dB(A)

- Results: 15% improvement in image signal-to-noise ratio and 20% reduction in scanning time

3.3 Data Center Cooling

Case Study: Edge Computing Node

- Challenge: High-density server racks experienced local hotspots causing CPU throttling

- offering: Deployed SM3100 liquid cooling modules with direct-contact cold plates keep CPU temperatures below 65°C

- Results: Achieved PUE (Power Usage Effectiveness) of 1.15, with annual electricity savings exceeding $28,000 per rack

4. Maintenance Strategies

4.1 Routine Inspection Protocol

- Pressure Monitoring: Daily recording of high-side and low-side pressure values - deviations require leak or blockage checks

- Vibration Testing: Regular vibration measurements at compressor-cooler junctions using vibrometers

- Electrical Inspection: Monthly verification of control module power input stability

4.2 Comprehensive Maintenance Procedures

- Condenser Cleaning: Quarterly high-pressure water cleaning of condenser fins to prevent dust accumulation

- Refrigerant Analysis: Semi-annual purity testing with condensate content checks

- Seal Replacement: Biennial replacement of O-rings in compressor-cooler connection pipes

4.3 Troubleshooting Guide

| Symptom | Potential Cause | offering |

|---|---|---|

| High Discharge Temperature | Dirty condenser/Insufficient refrigerant | Clean condenser/Recharge refrigerant |

| Frequent Compressor Cycling | Faulty pressure sensor/Control logic error | Replace sensor/Update firmware |

| Abnormal Noise | Fan bearing wear/Damaged vibration pads | Replace bearings/Vibration pads |

5. Technological Evolution and Industry Impact

5.1 Technology Development Timeline

- First Generation (2017): Introduced WindFree™ draft-free technology for air conditioning

- Second Generation (2020): SM3100 prototype validated microchannel thermal exchanger feasibility in industrial use cases

- Third Generation (2025): Mass-produced SM3100 with AI algorithms and IoT capabilities

5.2 Industry Contributions

- overall efficiency Standards: Pushed industrial cooling equipment COP values beyond 3.0 threshold

- Eco-Friendly Refrigerants: Pioneered large-scale R410A adoption in industrial use cases

- Smart Manufacturing: Open API interfaces facilitate Industry 4.0 transition

6. Conclusion

The Samsung Compressor Cooler SM3100 redefines operational performance benchmarks for industrial compressor coolers through its microchannel heat exchange technology, intelligent control system setup, and modular design. In high-value sectors like semiconductor, medical, and data center use cases, this product enhances equipment stability and energy overall efficiency, directly improving production efficiency and cost control. As Samsung continues investing in AIoT, the SM3100 is poised to integrate digital twin and predictive maintenance technologies, establishing itself as the cooling system setup standard for Industry 4.0.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM4100

View Details

View DetailsSamsung Compressor Cooler SM5100

View Details

View DetailsSamsung Compressor Cooler SM6100

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.