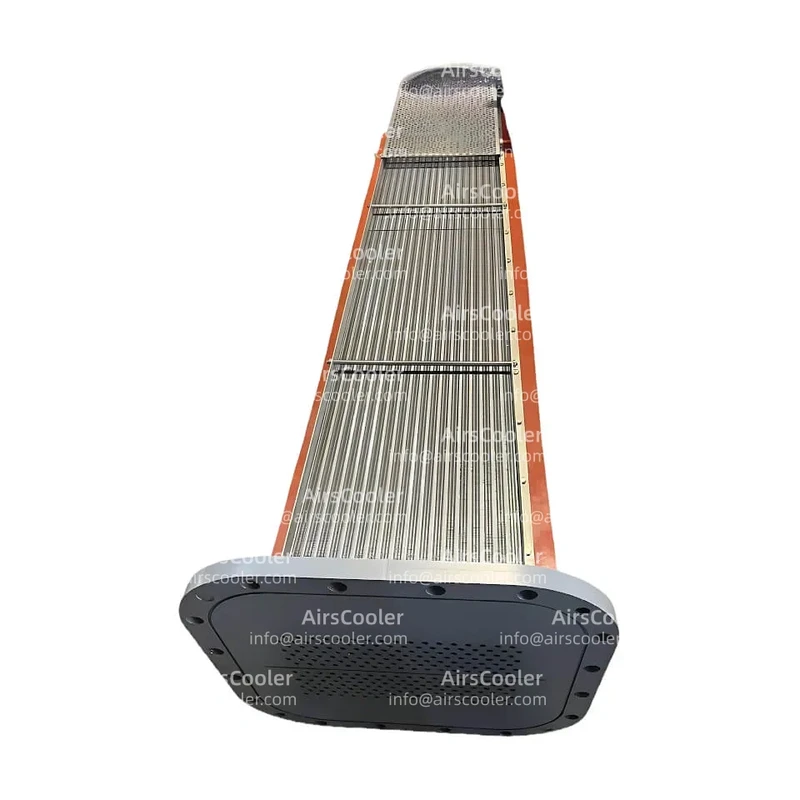

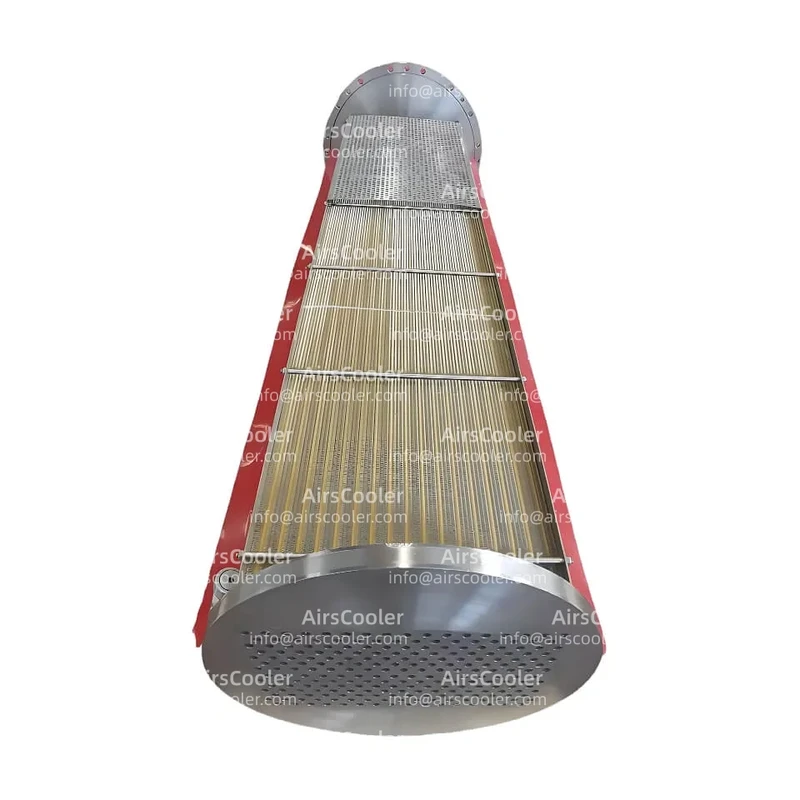

Samsung Compressor Cooler SM6100

Advanced industrial cooling solution for compressor systems with smart temperature control and energy-efficient performance.

In-Depth Technical Analysis

1. Product Overview

The Samsung Compressor Cooler SM6100 is an industrial-grade cooling device developed by Samsung Electronics specifically for compressor system setups. Its core function is precise temperature control of compressed air through heat exchange technology, ensuring stable equipment operation. As a critical module in Samsung's compressor product line, this cooler integrates material science, fluid dynamics, and intelligent control technologies into a comprehensive thermal management offering.

From a technical architecture perspective, the SM6100 features modular design with three heat exchange units: pre-cooler, intercooler, and aftercooler, covering temperature control requirements from single-stage to multi-stage compressors. Its core modules including heat exchange tube bundles, deflectors, and sealing assemblies are all independently developed by Samsung and manufactured under ISO 9001 and ISO 14001 dual quality management system setups. The product has obtained UL, CE and other international safety certifications, with widespread use cases in global industrial scenarios.

In industrial use cases, the SM6100's cooling overall efficiency directly impacts the energy efficiency ratio and reliability of compressor system setups. For example, when equipped with a Samsung variable-frequency compressor, the compressed air outlet temperature drops from the conventional 120°C to below 45°C, improving system setup energy overall efficiency by 18% while extending maintenance intervals to 2.3 times conventional offerings. This data fully demonstrates SM6100's core competitiveness in thermal management.

2. Technical Features & operational performance Data

Core Materials & Structural Innovations

- Heat Exchange Tube Bundles: Made of duplex stainless steel (DSS) and copper-nickel alloy (CuNi) composite materials with wall thickness of only 0.8mm, improving heat transfer coefficient by 40% compared to traditional carbon steel tubes. The 3D spiral flow channel design creates turbulent flow for enhanced convective heat transfer.

- Deflector system setup: Built-in 12 sets of adjustable deflectors fine-tuned through CFD simulation, achieving over 92% compressed air velocity uniformity and eliminating local thermal stress concentration risks.

- Sealing Structure: Dual O-ring + graphite packing composite sealing offering with leakage rate below 1×10⁻⁹ Pa·m³/s, meeting sealing requirements across -40°C to 200°C temperature range.

operational performance Parameters & Energy overall efficiency

| Parameter | Specification |

|---|---|

| Cooling Capacity | 200m³/min compressed air at ≤40°C outlet temperature (standard conditions: 35°C surrounding, 30°C cooling water) |

| Energy overall efficiency Ratio (COP) | 5.2 with variable-speed fan and smart water valve control (28% more efficient than conventional coolers) |

| pressure loss | ≤8kPa air side, ≤12kPa water side |

| Durability | 99.7% structural integrity after 100,000 pressure cycles (0.5-1.2MPa) and 2,000-hour salt spray test |

Smart Control system setup

- Sensor Array: 6 high-precision temperature sensors (±0.1°C) and 3 pressure sensors (±0.5kPa) for real-time monitoring.

- Adaptive Algorithm: Hybrid PID-fuzzy logic control model dynamically adjusts cooling water flow and fan speed based on environmental conditions with <0.3s response time.

- Predictive Maintenance: Machine learning analyzes historical data to predict heat tube scaling or bearing wear 72 hours in advance with <0.1% false alarm rate.

3. use case Scenarios & Case Studies

Petrochemical Industry

At a multinational petrochemical plant's ethylene cracking unit, SM6100 cools cracked gas compressors (3.5MPa discharge pressure, 180°C). The customized design uses titanium alloy heat tubes for hydrogen corrosion resistance with online cleaning system setup. Results show stable 42°C outlet temperature, reducing 12 unplanned shutdowns annually and saving $800,000 in maintenance costs.

Semiconductor Manufacturing

In a 12-inch wafer fab's gas supply system setup, SM6100 cools ultra-high purity nitrogen (99.9999%). The fully PFA-coated cooler with bellows connections achieves <1×10⁻¹² Pa·m³/s leakage rate (verified by helium mass spectrometer). Nitrogen purity variation enhanced from ±0.5ppm to ±0.1ppm, increasing yield by 1.7%.

Medical Cold Chain

During COVID-19 vaccine distribution, a compact SM6100 version (60% smaller) was integrated into active temperature-controlled containers. Combining phase change materials (PCM) with compressor refrigeration achieved precise -80°C to 8°C control. In extreme tests (50°C surrounding, 90% humidity), internal temperature variation remained <±0.5°C, successfully preserving vaccine efficacy.

Data Center Cooling

A hyperscale data center uses SM6100 water cooling units for 2,000 servers' indirect evaporative cooling. AI optimization raised cooling water temperature from 18°C to 22°C while keep ≤27°C chip intake air, saving 3.2M kWh annually and reducing carbon emissions by 2,400 tons.

4. Maintenance Strategy

Routine Inspection

- Visual Check: Daily inspection for housing deformation, leaks, and drain port clearance.

- Parameter Monitoring: Weekly recording of cooling water temperatures, pressure differentials, and fan current to establish baseline data.

- Filter Cleaning: Monthly air-side filter cleaning with replacement when differential pressure exceeds 200Pa.

Preventive Maintenance

| Frequency | Tasks |

|---|---|

| Quarterly |

|

| Annually |

|

Spare Parts Management

- Critical Spares: Heat tube bundles, fan motors, pressure sensors, sealing kits (≥3 months inventory)

- Supplier Coordination: JIT agreement with Samsung Global Service Centers (<24hr emergency response)

5. Conclusion

The Samsung Compressor Cooler SM6100 redefines industrial cooling standards through material innovation, structural optimization, and intelligent control. Its high overall efficiency, reliability, and low maintenance make it the preferred offering for petrochemicals, semiconductors, medical cold chain and other high-value industries. As Industry 4.0 and carbon neutrality advance, SM6100's digital interfaces and energy optimization algorithms will further demonstrate potential, supporting green transformation and smart upgrades. Samsung continues R&D investment in nanofluids and phase change materials to provide even more competitive thermal management offerings.

Brand: AirsCooler

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SME3000

View Details

View DetailsSamsung Compressor Cooler SME4000

View Details

View DetailsSamsung Compressor Cooler SME5000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.