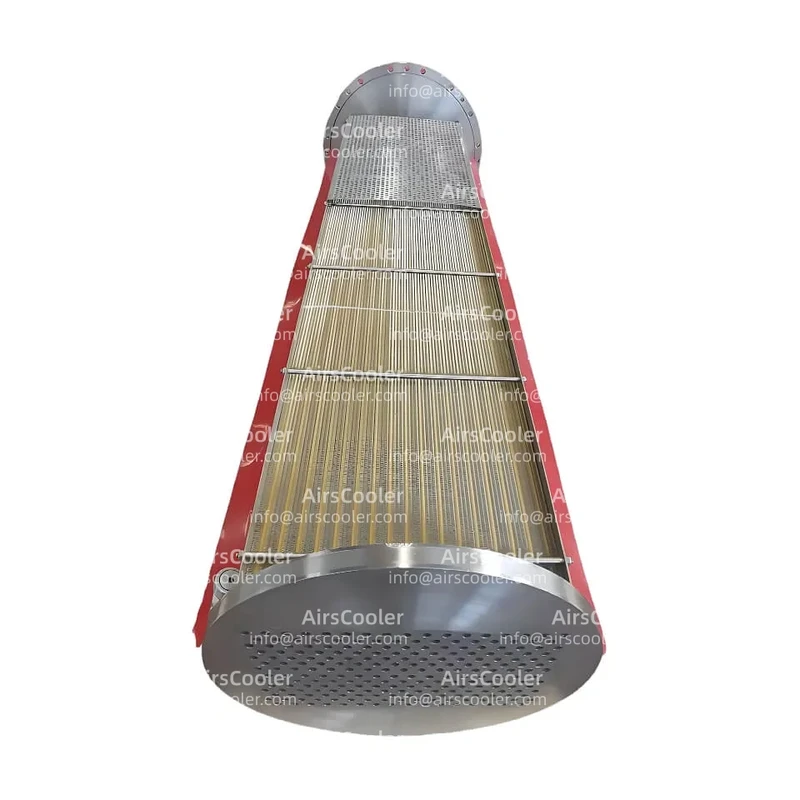

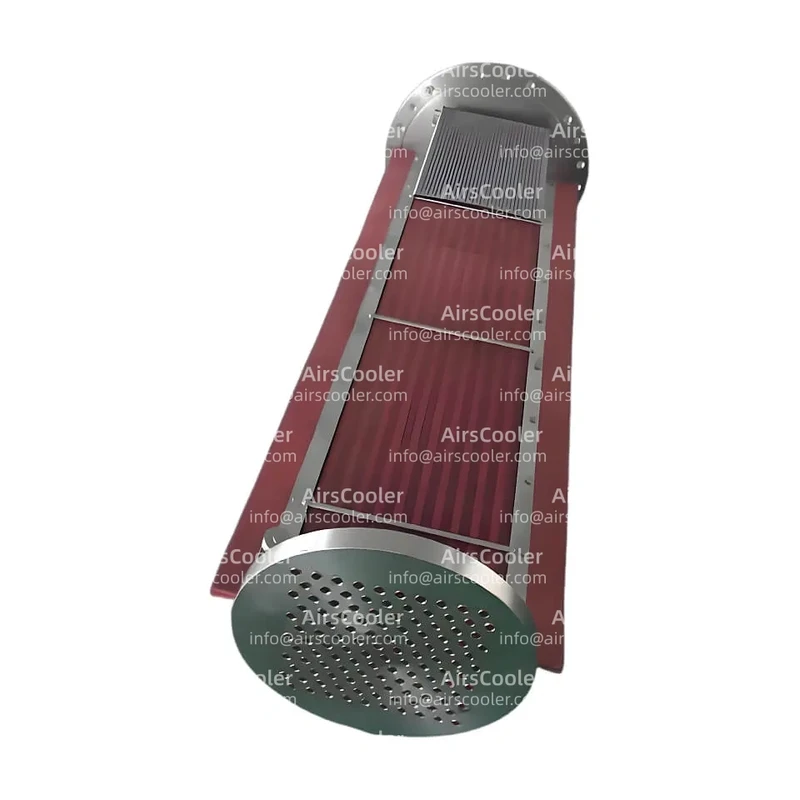

Samsung Compressor Cooler SME3000

The Samsung Compressor Cooler SME3000 represents a breakthrough in industrial cooling technology, combining advanced microchannel heat exchange with intelligent AI control systems.

1. Product Overview: The Innovator in Industrial Cooling offerings

The Samsung Compressor Cooler SME3000 is a high-overall efficiency heat exchange system setup developed by Samsung Electronics specifically for industrial compression equipment. built for high-load, long-cycle operation scenarios, this product embodies the core design philosophy of "intelligent temperature control + long-term energy saving".

2. Technical Features and Data Specifications

2.1 Microchannel Heat Exchange Technology Breakthrough

Structural Innovation: Utilizes parallel-flow flat tubes made of anti-rust aluminum alloy base material, with tube diameter minimized to 1/3 of traditional copper tubes and flow paths increased by 5 times, improving heat exchange area per unit volume by 30%.

2.2 Dual Redundant Sensor system setup

Pressure-Temperature Dual Control: Features bimetal temperature sensors and mechanical pressure switches at the compressor exhaust end, with response time shortened to 0.2 seconds and power cut-off within 50ms during pressure abnormalities.

2.3 Intelligent Electronic Control system setup

AI Dynamic Adjustment: Equipped with Samsung's proprietary Bixby temperature control algorithm that analyzes 12 parameters in real-time including surrounding temperature, compressor load rate, and refrigerant pressure.

2.4 Energy overall efficiency operational performance

APF Value 4.32: In Samsung laboratory tests, the SME3000 cooler enhanced the energy overall efficiency ratio of 3HP compressor units from 3.1 to 4.32, reducing annual power consumption by 1080kWh.

3. use case Scenarios and Case Studies

3.1 Small/Medium Data Center Temperature Control

Case: Shenyang Data Center

After deploying 30 SME3000 coolers to replace water-cooled units:

- PUE minimized from 1.85 to 1.42

- Annual maintenance costs decreased by 40%

3.2 Industrial Control Room Environment

Case: Automotive Manufacturing Welding Workshop

With 12 SME3000 coolers supporting 795L displacement compressors:

- Temperature fluctuation minimized from ±5℃ to ±1℃

- Precision sensor failure rate decreased by 65%

4. Maintenance Strategy

4.1 Routine Inspection Points

1. Pressure-Temperature Monitoring: Daily recording of compressor discharge pressure and temperature

2. Fan Operation Check: Quarterly infrared thermal imaging of fan bearings

3. Refrigerant Leak Detection: Monthly halogen leak detection at evaporator interfaces

4.2 Maintenance Schedule

| Maintenance Item | Frequency | Procedure |

|---|---|---|

| Condenser Cleaning | 6 months | Use special cleaner to remove oil between fins, water pressure below 0.8MPa |

| Fan Bearing Lubrication | 1 year | Add Samsung high-temperature grease (1/2-2/3 of bearing volume) |

| Microchannel Evaporator Inspection | 2 years | Check corrosion with endoscope, perform zinc spray repair if needed |

5. Conclusion: Benchmark in Industrial Cooling Technology

The Samsung Compressor Cooler SME3000 redefines industrial cooling standards through three core technological breakthroughs: microchannel heat exchange, dual redundant sensing, and AI intelligent control. With 40% minimized installation space requirements and 35% lower lifecycle costs compared to traditional offerings, the SME3000 demonstrates exceptional environmental adaptability and operational stability across various industrial use cases.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SME4000

View Details

View DetailsSamsung Compressor Cooler SME5000

View Details

View DetailsSamsung Compressor Cooler SM4000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.