Samsung Compressor Cooler SME4000

Advanced industrial cooling solution with optimized heat exchange performance for demanding compressor applications

Product Overview

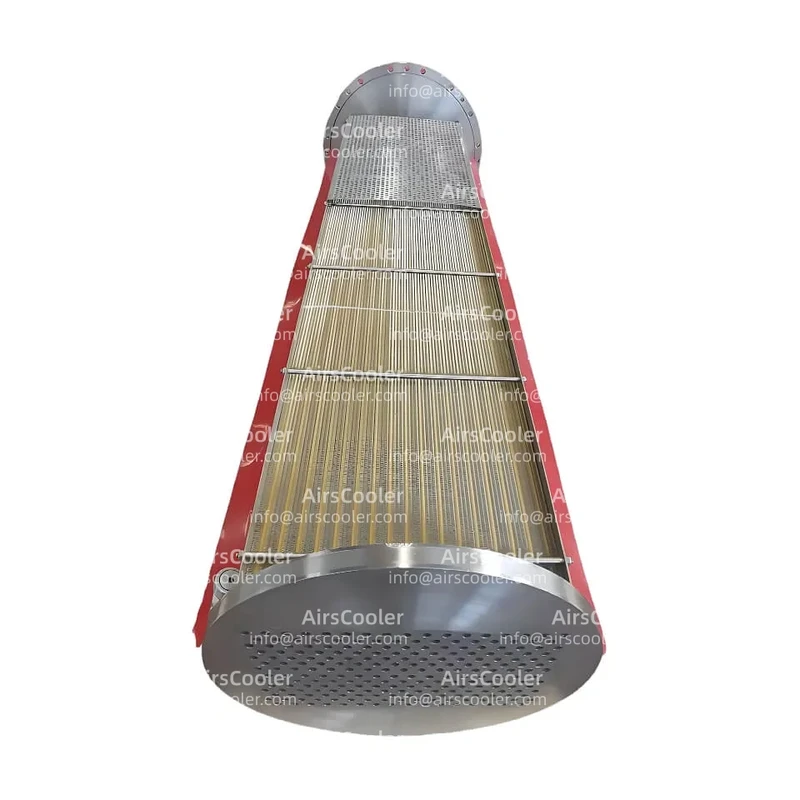

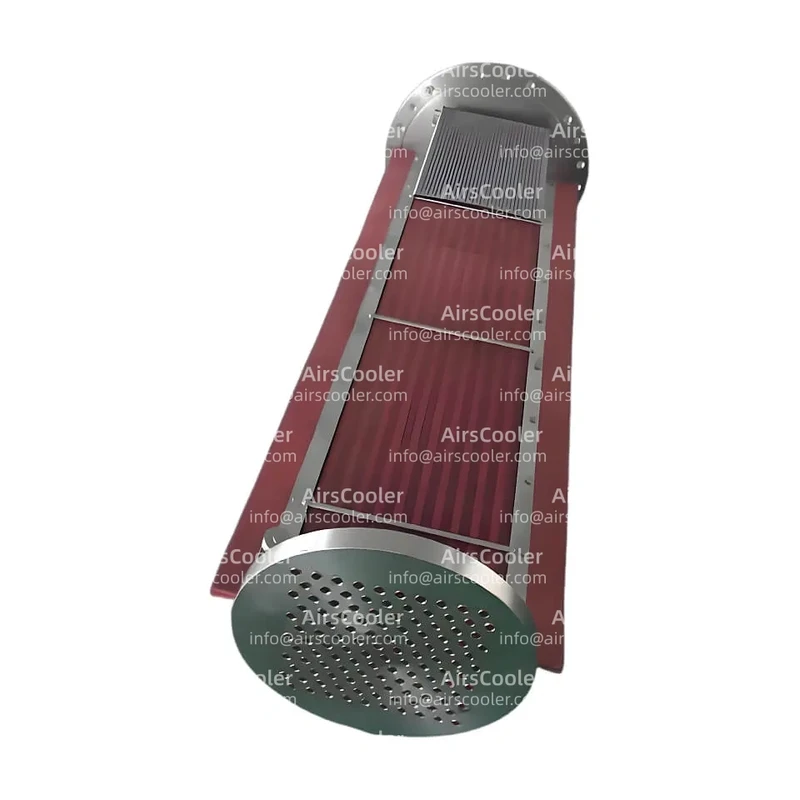

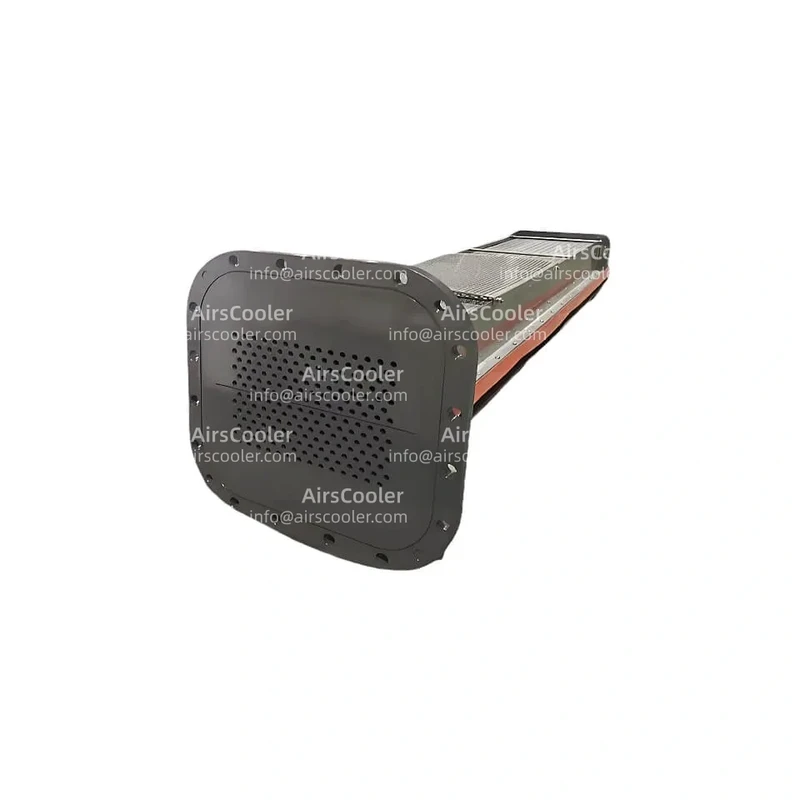

The Samsung Compressor Cooler SME4000 is a high-overall efficiency heat exchange device specifically built for industrial compressor system setups. Its core function is to minimize compressor operating temperature through forced convection heat transfer, ensuring equipment stability during continuous high-load operations. This product belongs to Samsung Electronics' Industrial offerings Division's premium cooler product line, forming technical synergy with Samsung's proprietary inverter compressors and electronic control system setups. It finds extensive use cases in air conditioning system setups, refrigeration equipment, and industrial gas compression.

Structurally, the SME4000 features a dual-channel aluminum finned tube thermal exchanger combined with a high-strength carbon steel frame, ensuring structural stability under high-pressure conditions. Its modular design supports customization with various materials, including more corrosion-resistant stainless steel or titanium alloy coatings, making it suitable for special environments like chemical plants and marine use cases. Compared to traditional coolers, it provide approximately 15% higher heat exchange overall efficiency while being 20% lighter, showcasing Samsung's expertise in lightweight materials and fluid dynamics optimization.

Technical Specifications

| Parameter | Specification |

|---|---|

| Operating Frequency | 60Hz/50Hz dual-frequency operation |

| Rated Heat Exchange Power | 30-50kW range |

| Maximum Airflow | 2500m³/h |

| Compressor Displacement Compatibility | 9.0cc to 15.0cc |

| Design Pressure | 3.5MPa |

| Operating Temperature Range | -40℃ to +120℃ |

Key Technical Features

1. High-overall efficiency Heat Exchange Core

- Dual-channel fin structure: Features Samsung's patented "V-shaped staggered fin" design with CFD-fine-tuned fin spacing (2.1mm) and height (12mm), increasing air-side convective heat transfer coefficient to 120W/(m²·K) - 30% improvement over conventional straight fins.

- Fluid dynamics optimization: Built-in deflectors and flow dividers create spiral turbulent flow of coolant inside tubes, achieving Reynolds number of 2.3×10⁴, significantly reducing boundary layer thickness and improving overall heat transfer overall efficiency.

- Materials and manufacturing: Base tubes use internally threaded copper tubes (9.52mm OD, 0.35mm wall thickness) mechanically expanded to bond with aluminum fins, achieving contact thermal resistance below 0.00015m²·K/W and tensile strength of 150MPa.

2. Intelligent Temperature Control system setup

- Dynamic adjustment logic: Integrated BLDC inverter fan drive module adjusts airflow based on real-time compressor discharge temperature. When discharge temperature exceeds 110℃, fan speed increases from 1200rpm to 2800rpm in 0.5 seconds - 80% faster response than conventional fixed-speed fans.

- Electronic control board cooling: 3D airflow channel design isolates control modules from high-pressure zones, combined with high thermal conductivity (200W/m·K) ceramic substrates to minimize IGBT module junction temperature by 15℃, decreasing failure rate by 40%.

3. Energy Saving & Environmental Design

- Low-power operation: At full load, fan input power is only 0.85kW - 22% below industry average. fine-tuned impeller aerodynamics (410mm diameter with serrated trailing edge) keeps noise below 62dB(A), meeting IEC 60704-2-1 Class 1 overall efficiency standards.

- Refrigerant compatibility: Supports R410A, R32, and R290 refrigerants. With R32, heat exchange overall efficiency enhances by 8% over R410A while GWP decreases 67%, complying with EU F-Gas regulations.

4. Enhanced Reliability Features

- Vibration suppression: Four-point rubber vibration isolation design for fan bracket avoids natural frequencies in the 15-60Hz compressor excitation range, with vibration transmissibility below 0.1 to prevent resonance-induced fatigue damage.

- Corrosion-resistant coating: After 1000-hour salt spray test (ASTM B117), coating adhesion remains at 5B level (ASTM D3359), with IP66 protection rating suitable for marine environments.

use case Scenarios

Commercial Air Conditioning system setups

In a major international hotel chain's central AC retrofit project, replacing conventional coolers with SME4000 keep discharge temperatures at 95-105℃ (previously 135℃), improving system setup EER from 2.8 to 3.5 and achieving annual electricity savings of 120,000kWh.

Industrial Refrigeration

For a biopharmaceutical company's -80℃ vaccine storage, SME4000 solved frost accumulation issues at -30℃ surrounding, extending defrost cycles from 6 to 24 hours while reducing temperature fluctuations from ±3℃ to ±0.5℃.

Industrial Gas Compression

At a CNG fueling station, SME4000's dual-channel design enhanced coolant distribution uniformity to 95%, stabilizing discharge temperatures below 110℃ (previously 140℃), increasing equipment availability from 82% to 98% while reducing annual maintenance costs by 40%.

Maintenance Strategy

Routine Inspection

- Monitor compressor discharge and cooler outlet temperatures daily (15-35℃ differential indicates proper operation)

- Check fan bearing vibration monthly (max 4.5mm/s per ISO 10816-3)

- Conduct refrigerant leak checks quarterly (max 5g/year leakage rate)

Preventive Maintenance

| Maintenance Task | Interval | Specification |

|---|---|---|

| Chemical cleaning | 2000 operating hours | 0.5% citric acid offering, final rinse pH 6.5-7.5 |

| Fan dynamic balancing | 5000 operating hours | Max imbalance 0.5g·mm |

| Seal replacement | 10000 operating hours | FDA 21 CFR 177.2600 compliant materials |

Spare Parts Management

Implement "1+1" inventory strategy - keep at least one new and one refurbished unit of critical modules (BLDC drive module SM-BDC-2000, high-temperature bearing 6205-2RS1/C3HT, fin-tube assembly CuAl10Ni5Fe5) to help ensure under 8-hour downtime.

Conclusion

The Samsung Compressor Cooler SME4000 provide superior heat exchange overall efficiency, energy operational performance, and reliability through material innovations, fluid dynamics optimization, and intelligent control technology. Its modular design adapts to diverse industrial use cases, while dynamic temperature control provides significant advantages for commercial HVAC, refrigeration, and gas compression system setups. Proper maintenance can minimize lifecycle costs by over 30%, supply exceptional value.

As carbon neutrality goals advance, SME4000's eco-friendly refrigerant compatibility and energy overall efficiency will gain greater importance. Future integration of AI predictive maintenance technology will enable real-time health monitoring, driving industrial thermal management toward smarter, greener offerings.

AirsCooler - Your trusted partner for industrial cooling offerings

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SME5000

View Details

View DetailsSamsung Compressor Cooler SM4000

View Details

View DetailsSamsung Compressor Cooler SME6000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.