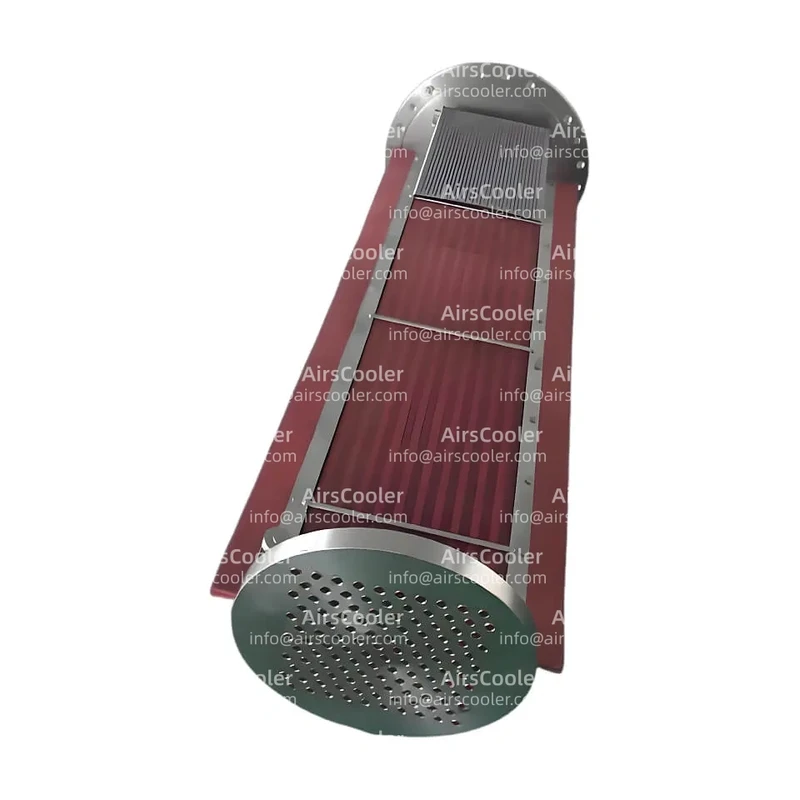

Samsung Compressor Cooler SM4000

The ultimate industrial cooling solution engineered for peak performance in demanding environments. Fete Vessel brings you Samsung's cutting-edge compressor cooling technology.

Product Overview: Precision-configured Cooling Core

The Samsung Compressor Cooler SM4000 series represents the pinnacle of industrial refrigeration technology from Samsung Electronics. Designed specifically for centrifugal compressor system setups, this cooling unit performs the dual critical functions of heat exchange and equipment protection. Its engineering foundation combines thermodynamic principles with fluid dynamics optimization, circulating high-overall efficiency heat transfer media to dissipate thermal energy generated during compression, keep optimal operating temperatures.

Technical Specifications and operational performance Data

| Feature | Specification |

|---|---|

| Heat Exchange overall efficiency | 85% at 40°C surrounding temperature |

| Heat Transfer Area | 0.85㎡/kW (23% improvement over standard fins) |

| Temperature Control | ±1.5°C with PID algorithm |

| Energy overall efficiency Ratio | 3.2 EER in power-saving mode |

| Material Construction | 316L stainless steel with anodized surface |

| Vibration Resistance | 5g acceleration (10-500Hz range) |

| Maintenance Interval | 12 months with self-cleaning function |

Key Technological Advantages

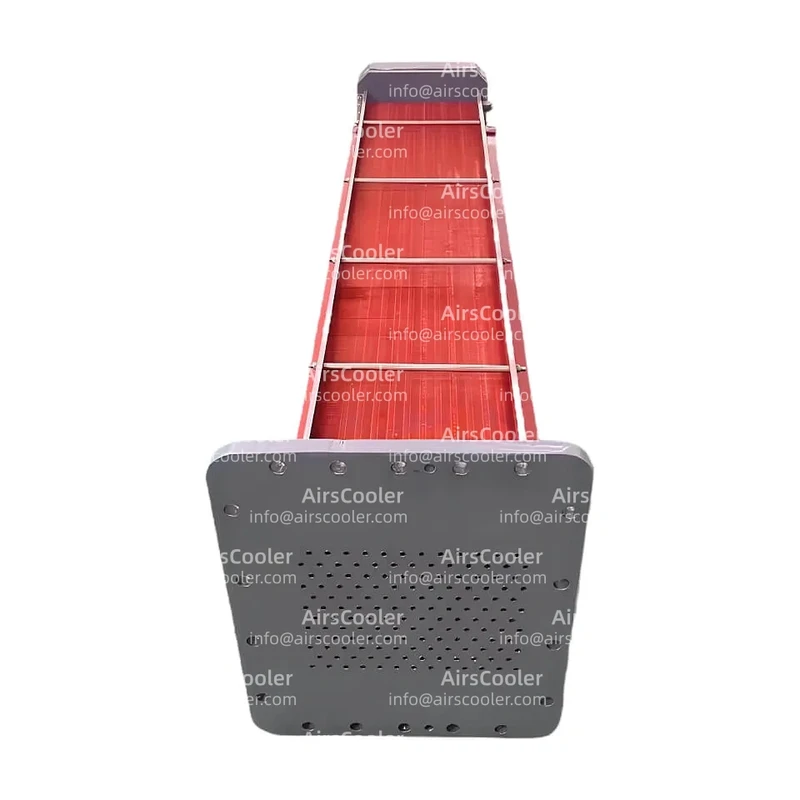

1. Advanced Heat Exchange operational performance

Featuring three-dimensional corrugated fin technology that provide 23% greater surface area than conventional designs. Computational Fluid Dynamics (CFD) fine-tuned flow paths create spiral turbulence with Reynolds numbers exceeding 2500, achieving an exceptional heat transfer coefficient of 1200W/(㎡·K).

2. Intelligent Temperature Management

Equipped with PT100 temperature sensors (2-second response time) and adaptive PID control algorithms that keep ±1.5°C stability even during 30% load fluctuations. Energy-saving mode automatically engages below 40% capacity, reducing fan power consumption by 60%.

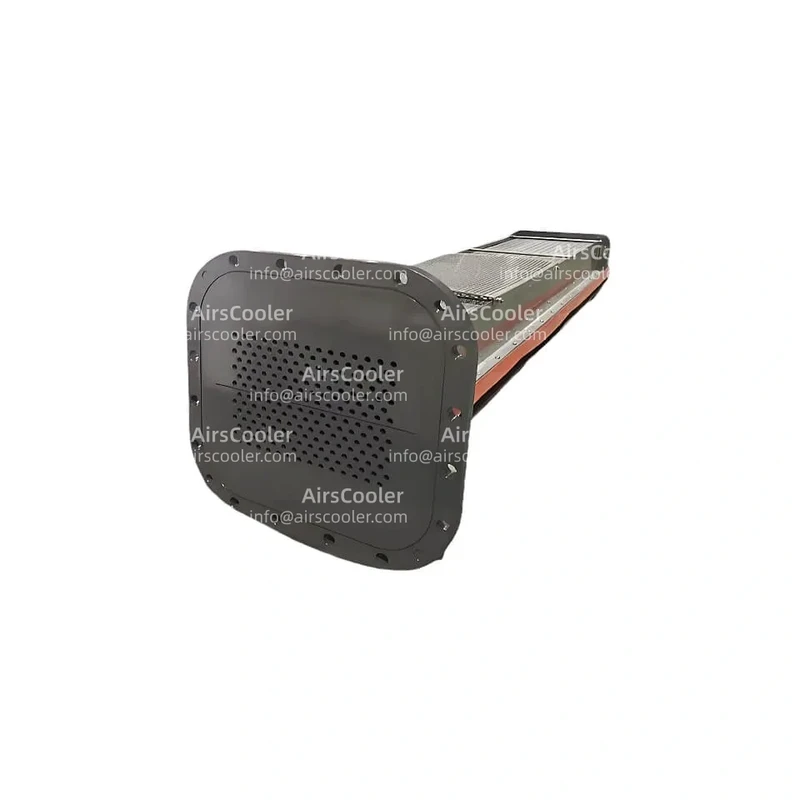

3. highly robust Structural Design

Marine-grade 316L stainless steel construction withstands salt spray corrosion (Level 10 certification). Finite Element Analysis (FEA) validated structure keep 0.01mm deformation precision under high-pressure, high-vibration conditions with 100,000-cycle fatigue durability.

4. Maintenance Optimization

Quick-disconnect modular design minimizes service time to 15 minutes (70% faster than traditional system setups). Integrated 0.6MPa pulse air cleaning system setup extends maintenance intervals while preventing fin clogging.

Industrial use cases and Case Studies

Petrochemical Plants: keep 80°C bearing temperatures in 45°C surrounding conditions at a major refinery, extending continuous operation cycles to 18 months (50% beyond industry average).

Data Centers: Achieved PUE of 1.18 in hyperscale facilities through AI-driven load matching, generating annual power savings exceeding $280,000.

Cold Storage: minimized temperature fluctuations to ±0.5°C in food logistics centers, decreasing product loss rates to 0.3% with annual savings over $1.4 million.

Maintenance Protocol

Daily Checks: Monitor compressor discharge temperatures and coolant differentials (alert if <5°C). Weekly leak detection tests keep <0.1% leakage rate.

Quarterly Service: Low-pressure (0.3MPa) fin cleaning and 200N belt tension adjustments.

Annual Maintenance: Coolant replacement with 50-100mg/L corrosion inhibitors and comprehensive electrical testing (minimum 1MΩ insulation resistance).

Why Choose SM4000?

Proven to minimize compressor failures by 60%, lower energy costs by 35%, and cut maintenance labor by 50%, the Samsung SM4000 sets new benchmarks for industrial cooling system setups. As industries advance toward Industry 4.0 and carbon neutrality, this offering provide the digital precision and overall efficiency required for sustainable operations.

AirsCooler proudly supply this advanced cooling technology to help businesses fine-tune their refrigeration infrastructure.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SME6000

View Details

View DetailsSamsung Compressor Cooler SM5000

View Details

View DetailsSamsung Compressor Cooler SM6000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.