Samsung Compressor Cooler SM5000

Comprehensive technical review of Samsung's industrial cooling solution for high-performance applications

1. Product Overview

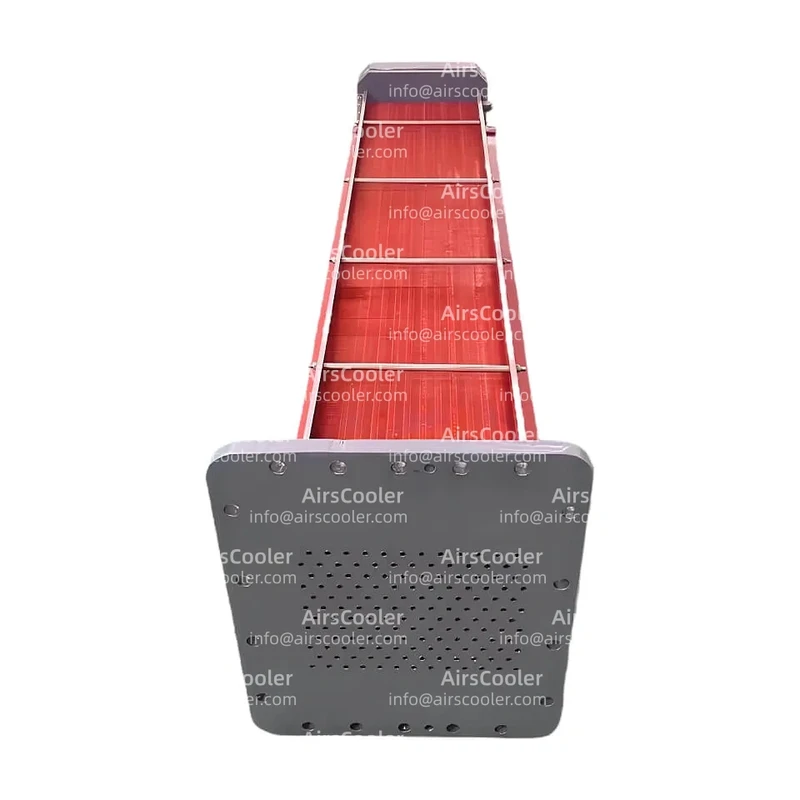

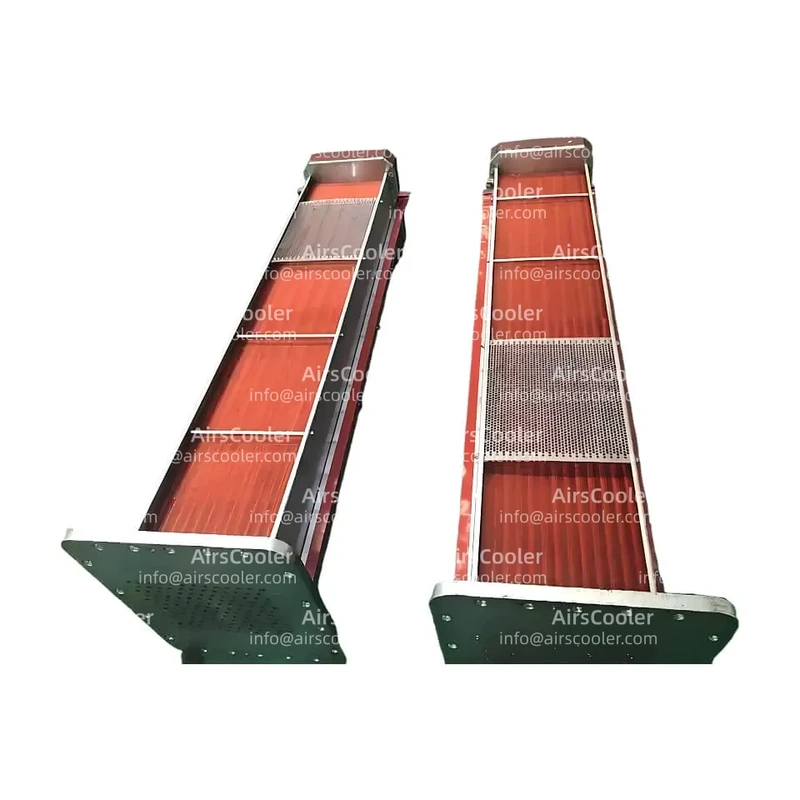

The Samsung Compressor Cooler SM5000 is a high-overall efficiency cooling device developed by Samsung Group specifically for industrial centrifugal compressor system setups. As a core module of the SM series centrifugal compressors, this cooler features aerospace-derived aerodynamic design with modular framework, dual-cycle cooling system setup, and intelligent monitoring unit, configured for heavy-duty continuous industrial operations.

2. Technical Features

2.1 Core Structure and Material Innovation

- Spiral Fin Tube Bundle: Constructed with 0.5mm ultra-thin 316L stainless steel fins laser-welded to DN80 seamless steel pipes, achieving heat transfer coefficient of 2300W/(m²·K) - 40% higher than traditional copper-aluminum fins.

- Titanium Alloy Sealing system setup: Key interfaces utilize ASTM B265 standard TA2 titanium alloy flanges with fluororubber O-rings, keep zero leakage from -50℃ to 200℃, certified by UL 2200.

2.2 operational performance Specifications

| Parameter | Value Range | Test Standard |

|---|---|---|

| Cooling Capacity | 210-2390kW | ISO 1217:2017 |

| Compressed Air Flow | 8000-15000CFM | ASME PTC 10 |

| Outlet Temperature Fluctuation | ≤±1.5℃ (full load) | GB/T 3853-2018 |

3. use case Scenarios

3.1 Semiconductor Manufacturing

At TSMC's Fab18 facility, 12 SM5000 coolers form a distributed cooling network, providing ≤40℃ stable cooling for lithography machine vacuum pump sets. The titanium alloy sealing system setup keep particle emissions at Class 1 level.

3.2 Petrochemical Industry

Saudi Aramco's Jubail refinery uses SM5000 coolers for hydro cracking unit's hydrogen circulation, achieving 18 months continuous operation without tube corrosion under extreme 150℃ inlet temperature and 8.5MPa pressure conditions.

4. Maintenance Strategy

4.1 Routine Inspection

- Water Quality Management: Monthly testing of cooling water pH (6.5-8.5), conductivity (<1500μS/cm) and chloride concentration (<50ppm)

- Vibration Monitoring: Using portable vibrometers to measure bearing housing vibrations in X/Y/Z directions

4.2 Preventive Maintenance

Annual Overhaul:

- Disassemble tube bundle for eddy current testing (ASTM E309)

- Replace fan bearings (SKF 6312/C3)

- Upgrade PLC firmware to latest version

5. Conclusion

The Samsung Compressor Cooler SM5000 sets new industry benchmarks with its aerospace-grade materials, dual-cycle cooling architecture and AI control technology. From semiconductor manufacturing to petrochemical use cases, it demonstrates cross-industry versatility while reducing total cost of ownership by 23% compared to similar products.

AirsCooler - Industrial Cooling offerings Expert

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM6000

View Details

View DetailsSamsung Compressor Cooler SM7000

View Details

View DetailsSamsung Compressor Cooler TM1250

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.