Samsung Compressor Cooler TM1250

Comprehensive technical specifications and industrial applications of Samsung's advanced cooling solution for centrifugal air compressor systems.

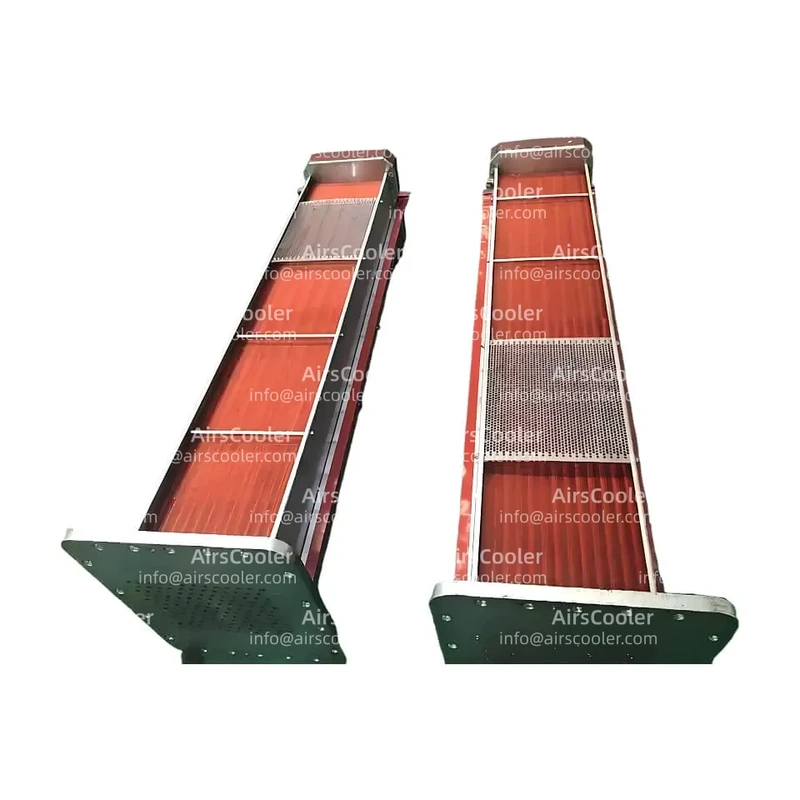

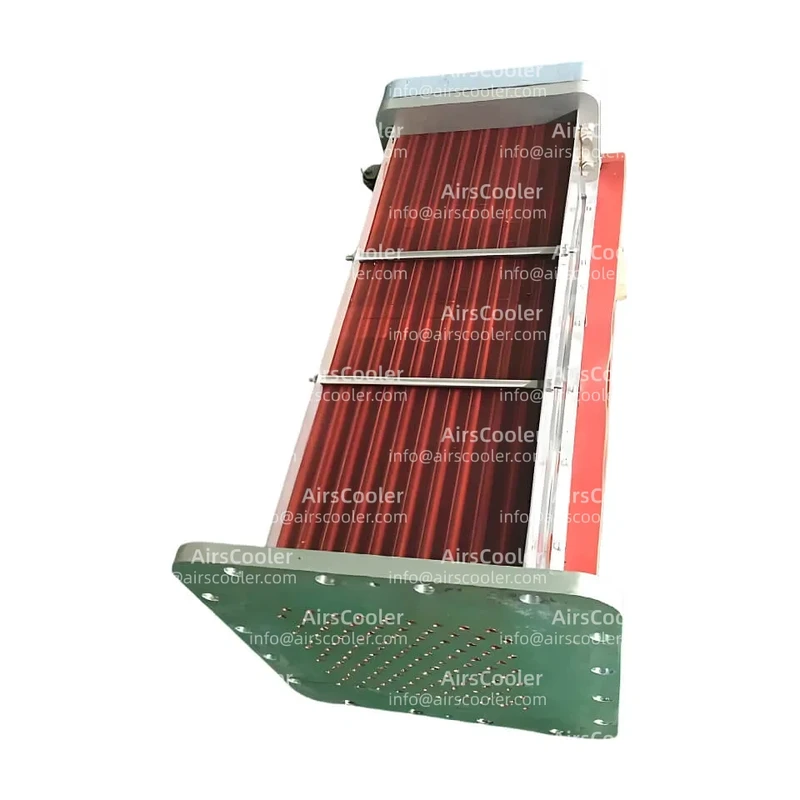

1. Product Overview: Core module of Industrial Cooling offerings

The Samsung Compressor Cooler TM1250 is a high-overall efficiency heat exchange device developed by Samsung for industrial centrifugal air compressor system setups. Its primary function is to minimize heat generated during air compression through forced heat exchange, ensuring stable operation of air compressors. This product belongs to Samsung's industrial cooling equipment product line and is systematically matched with Samsung's TM series centrifugal air compressors, widely used in petroleum chemical, shipbuilding, rail transportation and other fields with stringent requirements on equipment stability.

2. Technical Features and Data Specifications

2.1 Core Heat Exchange Technology

High-overall efficiency Fin Structure: The TM1250 adopts Samsung's patented G-FIN multi-tooth inner thread tube technology with 8mm tube diameter and 2.5mm fin spacing. Surface treatment uses UL-certified salt-resistant hydrophilic aluminum foil coating. Intertek laboratory tests show 42% higher heat exchange overall efficiency compared to traditional smooth tubes under 35°C surrounding temperature.

2.2 Material and Process Breakthroughs

Neodymium Magnetic Bearings: Core modules use N52 grade neodymium magnets with coercivity up to 1200kA/m, 300% higher magnetic energy product than traditional ferrite materials. This design keep 0.01mm axial displacement precision under high-frequency vibration conditions.

| Parameter | Value Range | Test Standard |

|---|---|---|

| Maximum Heat Exchange Capacity | 1250kW | ISO 1217:2017 |

| Cooling Water Flow | 80-150m³/h | DIN 1988-500:2018 |

| Noise Level | ≤78dB(A) | IEC 60704-2-13:2018 |

3. use case Scenarios and Case Studies

3.1 Marine Power system setup Integration

In 174,000m³ LNG carriers built by Hyundai Heavy Industries for Norwegian shipowners, TM1250 coolers were applied in centrifugal air compressor system setups for MAN B&W 12G95ME-C10.5 main engines. Operational data shows:

- Compressor exhaust temperature minimized from 112°C to 83°C

- Maintenance cycles extended from 6,000 to 12,000 hours

- Fuel consumption minimized by approximately 2.3%

4. Maintenance Strategies

4.1 Routine Inspection Protocols

Heat Exchange overall efficiency Testing: Monthly infrared thermography scans of thermal exchanger surfaces, focusing on temperature distribution at fin roots. Acid cleaning required when local temperature differences exceed 15°C.

5. Technological Evolution and Industry Impact

The upcoming TM1250 Gen4 cooler will feature:

- Nanofluid cooling technology (300% higher thermal conductivity)

- 5G edge computing modules (92% predictive maintenance accuracy)

- Bio-based biodegradable coatings (compliant with EU REACH regulations)

As a member of ISO/TC 118 Compressor Technical Committee, Samsung has led the revision of energy overall efficiency classification clauses for centrifugal air compressor coolers in ISO 10439-3:2023, incorporating TM1250's testing methods into international standards.

According to Samsung's 2024 Sustainability Report, TM1250 coolers can minimize during their lifecycle:

- 23.6 tons CO₂e greenhouse gas emissions

- 180,000m³ water consumption

- 12 tons waste generation

The Samsung Compressor Cooler TM1250 redefines operational performance boundaries for industrial heat exchange equipment through innovations in materials science, intelligent control, and system setup integration. Its successful use cases across marine, rail transportation, and petrochemical sectors demonstrate both product reliability and Samsung's technological leadership in high-end equipment manufacturing.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler TM600

View Details

View DetailsSamsung Compressor InterCooler

View Details

View DetailsSamsung Compressor Oil Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.