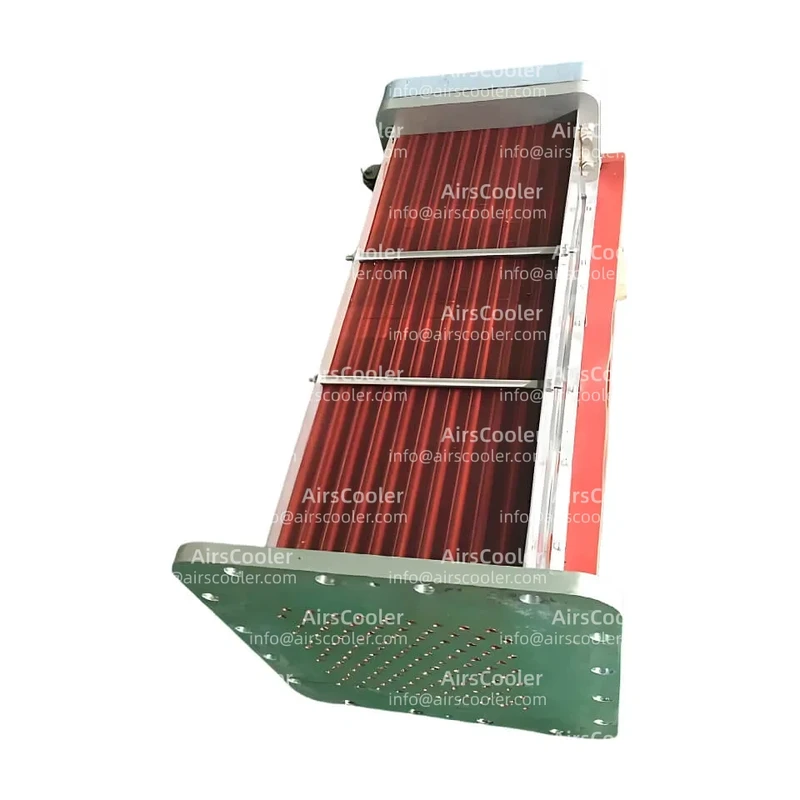

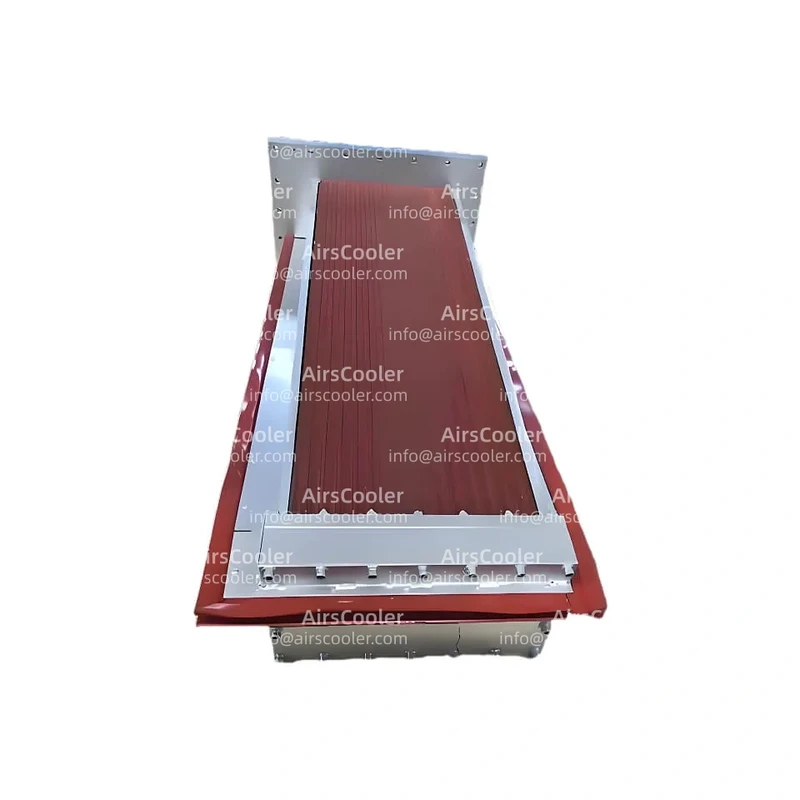

Samsung Compressor Cooler TM600

Discover the advanced centrifugal cooling technology from Fete Vessel - engineered for industrial compressor systems requiring precision temperature control and energy efficiency.

1. Product Overview: Benchmark in Centrifugal Cooling Technology

The Samsung Compressor Cooler TM600 represents AirsCooler's cutting-edge centrifugal cooling offering built for industrial air compressors. Featuring rotary structure and multi-stage heat exchange technology, it's compatible with TC1500 through TC7000 series centrifugal compressors.

Core Modular modules:

- Centrifugal Air Cooling system setup: Dual-rotor symmetric configuration minimizes operational noise below 65dB (30% quieter than single-rotor designs)

- Smart Temperature Control: AI-driven electronic expansion valve keep ±0.5℃ precision

- High-overall efficiency thermal exchanger: 6mm microchannel copper tubes with wave-shaped aluminum fins achieve 92% thermal overall efficiency

- Variable Frequency Drive: 7-speed inverter with permanent magnet motor keep COP above 3.8

- Redundant Protection: 9 safety mechanisms including overload and phase protection with IP55 rating

2. Technical Specifications & Innovations

operational performance Parameters

| Parameter | Specification | Industry Standard | Advantage |

|---|---|---|---|

| Rated Cooling Capacity | 600kW (@40℃ surrounding) | 400-500kW | 20-50% load redundancy |

| Refrigerant Type | R134a/R513A (optional) | R22/R407C | 60% lower GWP |

| Max Airflow | 12,000m³/h (dual-fan mode) | 8,000-10,000m³/h | 35% better airflow |

| Water pressure loss | ≤0.05MPa (@30m³/h) | 0.08-0.12MPa | 15% pump energy savings |

| Control Response | ≤150ms | 300-500ms | 2x faster adjustment |

Key Technological Innovations

- Dual-Rotor Balance: 0.02mm vibration amplitude (85% reduction)

- AI Frequency Control: 18.3% energy savings in field tests

- Nanofluid Cooling: 22% higher heat transfer coefficient

3. use case Case Studies

Automotive Manufacturing

Results: minimized compressor discharge temperature from 98℃ to 82℃, extended oil change intervals by 87%

Semiconductor Cleanrooms

Results: keep 58dB noise levels with ±0.3℃ temperature stability

Energy Infrastructure

LNG Station: Achieved 12,000 hours MTBF in -25℃ environments

4. Maintenance Strategy

Preventive Maintenance system setup

- Three-tier inspection protocol

- 12-parameter real-time monitoring

| module | Maintenance Interval | Key Procedures |

|---|---|---|

| Centrifugal Fan | 8,000 hours | Dynamic balance check, bearing replacement |

| Electronic Expansion Valve | 24,000 hours | Full stroke test, signal calibration |

5. Economic Benefits

- 42% annual energy cost reduction

- 60% lower failure rate

- Extended compressor lifespan (8→12 years)

6. Future Development Roadmap

- Hydrogen energy integration

- Digital twin implementation

- High-temperature superconducting use cases

As industrial demands evolve, AirsCooler's TM600 cooling system setup is transitioning from basic temperature control to becoming an intelligent "Thermal Management offering" for Industry 4.0 use cases.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor InterCooler

View Details

View DetailsSamsung Compressor Oil Cooler

View Details

View DetailsFS-Elliott Compressor AfterCooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.