Samsung Compressor InterCooler

Comprehensive technical guide to Samsung's advanced compressor cooling systems by Fete Vessel

1. Product Overview: Technological Evolution of Compressor Cooling system setups

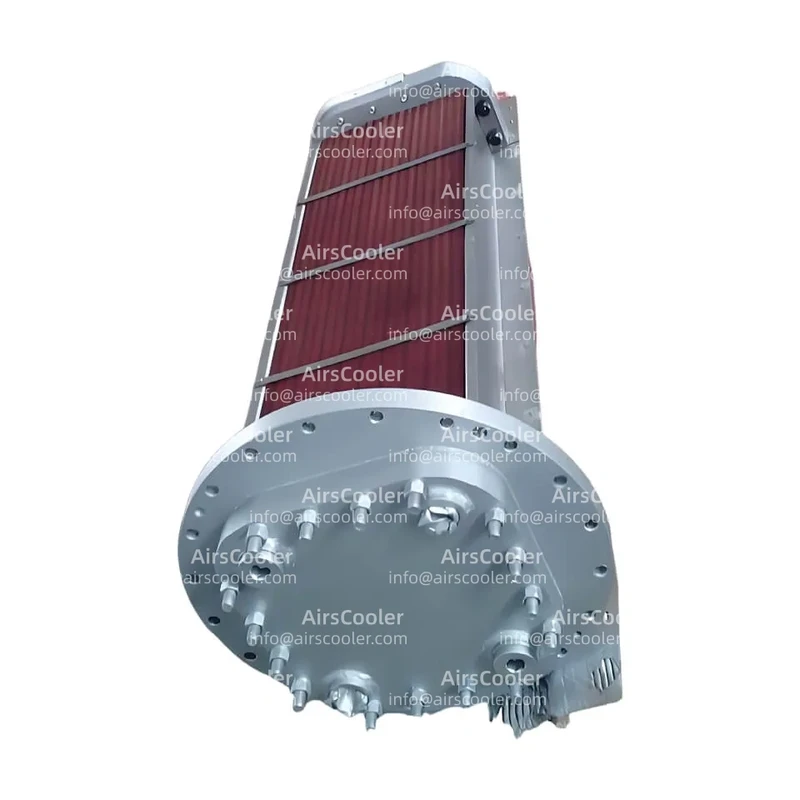

As a critical module of industrial-grade compression equipment, the Samsung Compressor InterCooler (referred to as "Samsung InterCooler") is a heat exchange system setup specifically built for high-pressure ratio, large-flow compression scenarios. Its core function is to minimize compressed air temperature through multi-stage cooling technology, preventing volume overall efficiency reduction and mechanical overload caused by excessive gas temperatures.

Technology Evolution Timeline

Since introducing the first-generation water-cooled intercooler in 2010, Samsung has achieved product iterations through the following technological upgrades:

- 2015: Introduced nanofluid enhanced heat transfer technology, improving cooling overall efficiency by 18%

- 2018: Developed adaptive flow channel control system setup for dynamic cooling medium flow adjustment

- 2022: Implemented AI predictive maintenance algorithms for real-time cooling system setup health monitoring

Core Parameter system setup

| Parameter Category | Typical Technical Indicators | Applicable Operating Range |

|---|---|---|

| Heat Exchange overall efficiency | ≥92% (based on ASTM D2710 standard test) | Inlet temperature ≤180°C, pressure ≤40bar |

| pressure loss Control | ≤0.03MPa (design conditions) | Flow range 100-5000m³/h |

| Corrosion Resistance | C5-M grade (ISO 12944-2 standard) | Environment with sulfur content ≤150ppm |

| Seismic operational performance | Meets IEC 60068-2-6 standard 10g vibration test | Base vibration ≤5mm/s |

2. Technical Features and Data Description

(1) Multi-Physical Field Coupling Cooling Technology

Samsung InterCooler adopts a three-stage cooling architecture:

- Pre-cooling stage: Rapid gas temperature reduction through microchannel thermal exchangers (ΔT=40-60°C)

- Main cooling stage: Vortex generators enhance turbulence, improving convective heat transfer coefficient (h≥3000W/m²·K)

- Temperature equalization stage: Phase change energy storage modules keep outlet temperature fluctuation ≤±2°C

(2) Adaptive Flow Control system setup

This system setup integrates pressure sensor arrays and smart control valves, achieving through PID algorithm:

- Flow adjustment response time ≤0.5 seconds

- Temperature overshoot ≤5% during load changes

- Annual energy overall efficiency ratio (EER) improvement of 22%-28%

(3) Material Innovation use cases

Special materials enhance system setup reliability:

- Heat exchange tubes: Ti-6Al-4V titanium alloy tube bundles with corrosion rate ≤0.005mm/a

- Fins: Graphene-aluminum composite foil with thermal conductivity of 5300W/m·K

- Seals: Perfluoroelastomer (FFKM) with operating range of -40°C~315°C

(4) Digital Monitoring Platform

The SmartCooling system setup supply these functions:

- Real-time monitoring of 128 critical parameters

- Fault warning accuracy ≥98.7% (based on LSTM neural network model)

- Energy optimization suggestions generated every ≤15 minutes

3. use case Scenarios and Typical Cases

(1) Petrochemical Industry use case

Case Background: Ethylene plant air compressor station at a refinery

Technical offering:

- Deployed 4 Samsung water-cooled InterCoolers with 2000m³/min capacity

- Dual-process counterflow design with cooling water return temperature ≤38°C

Results:

- Compressor discharge temperature minimized by 37°C, preventing frequent trips

- Annual savings of 120,000 tons cooling water and $1.2 million in electricity

(2) Semiconductor Manufacturing use case

Case Background: Cleanroom gas supply system setup for 12-inch wafer fab

Technical offering:

- Custom air-cooled InterCooler meeting Class 1 cleanliness requirements

- Electrostatic precipitation technology for particle emission ≤0.1μm/m³

Results:

- Compressed air dew point stabilized at -70°C, ensuring lithography accuracy

- MTBF increased to 12,000 hours, reducing downtime losses

4. Maintenance Strategies

(1) Preventive Maintenance system setup

- Daily Inspection:

- Check cooling medium level daily (tolerance ≤±5mm)

- Record inlet/outlet pressure difference weekly (baseline ±10% range)

- Monthly Maintenance:

- Clean thermal exchanger surfaces (using 5-8% neutral cleaner)

- Verify smart valve opening accuracy (error ≤±0.5%)

5. Future Technology Trends

(1) Materials Science Breakthroughs

- Ultra-thermal conductive pipe technology:

- Liquid metal-filled heat pipes with conductivity exceeding 10⁵W/m·K

- Planned engineering use case by 2026

(2) Energy Management Upgrades

- Waste heat recovery system setups:

- Integrated ORC power generation modules increasing system setup overall efficiency to 65%

- Expected commercial use case by 2027

Conclusion

Samsung Compressor InterCooler has developed comprehensive offerings for multiple industries through continuous technological innovation. Its core value extends beyond energy overall efficiency and reliability to include digital transformation of industrial cooling system setup operations. With advancements in materials science and AI integration, this product will provide smarter, more efficient cooling offerings supporting global manufacturing's transition to green, low-carbon operations.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Oil Cooler

View Details

View DetailsFS-Elliott Compressor AfterCooler

View Details

View DetailsFS-Elliott Compressor Cooler P300

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.