FS-Elliott Compressor Cooler P300

Comprehensive technical specifications and application solutions for Fete Vessel's industrial-grade compressor cooling system.

1. Product Overview

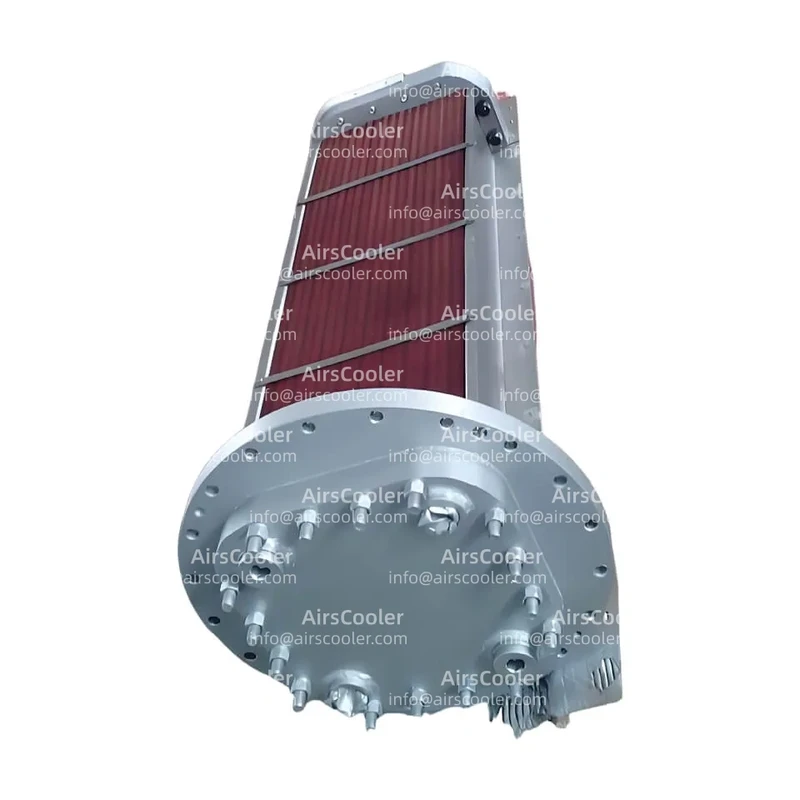

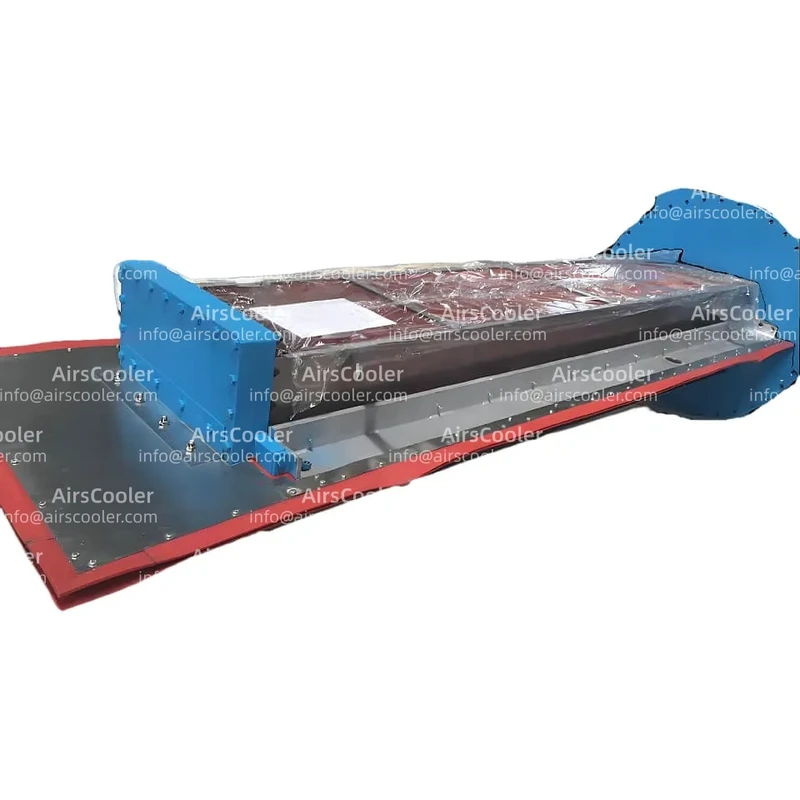

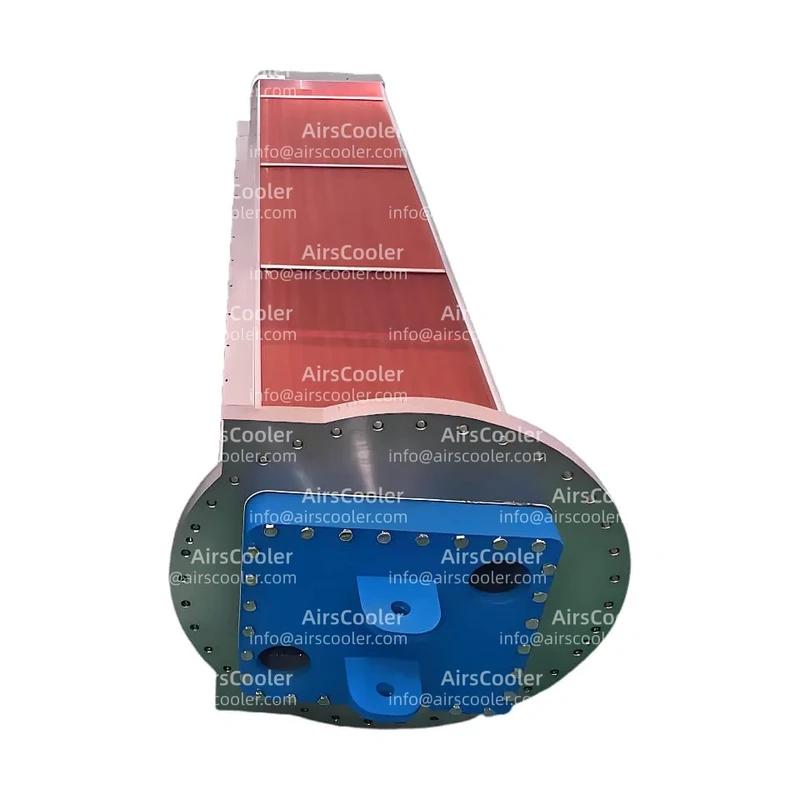

The FS-Elliott Compressor Cooler P300 is an industrial-grade cooling solution specifically built for centrifugal air compressors, serving as a critical module in the compressor's thermal management system setup. This modular cooler integrates seamlessly within P300 series centrifugal compressor units, connecting directly through straight-through cooling pipes to form a complete heat exchange circuit.

As part of FS-Elliott's Polaris® series compressors, the P300 cooler shares the same framework with the compressor gearbox, lubrication system setup, and control modules, significantly reducing installation space requirements. According to FS-Elliott technical documentation, this cooler supports P300 series two-stage and three-stage compression configurations, handling flow rates of 25-60 m³/min (900-2,220 CFM) and pressure ranges of 2.75-10.5 barg (40-150 psig).

2. Technical Features and Data Specifications

2.1 Structural Design and Material Innovation

Straight-through Cooling Pipes: The cooler features a double-pass shell-and-tube structure with cooling water flowing inside tubes and compressed air outside. The tube bundle uses Φ19×2mm seamless stainless steel with electrolytic polishing (surface roughness Ra≤0.4μm).

High-overall efficiency Fins: Spiral aluminum fins (3.2mm spacing, 12.7mm height) increase heat transfer area by 3.2× compared to smooth tubes, achieving heat transfer coefficients up to 120 W/(m²·K) while keep air-side pressure loss ≤1.5 kPa.

Industrial-grade Anti-corrosion Coating: The housing features two-module epoxy-polyester coating compliant with ISO 12944-5 C5-M standards, certified for 2,000 hours salt spray testing.

2.2 operational performance Parameters and overall efficiency Indicators

| Parameter | Specification | Certification Standard |

|---|---|---|

| Cooling Water Flow Range | 5-15 m³/h (adjustable) | ISO 9906:2012 Grade 1 |

| Cooling Water Inlet Temperature | 20-35℃ (recommended 25℃) | ANSI/ASHRAE 15-2019 |

| Maximum Allowable Pressure | 1.6 MPa (design pressure) | PED 2014/68/EU |

| Heat Exchange overall efficiency | ≥92% (measured) | ASHRAE Standard 41.2-2013 |

| pressure loss Control | Air side ≤1.5 kPa / Water side ≤0.2 MPa | API 617-2014 7th Ed. |

| Noise Level | ≤75 dB(A) (1m distance) | ISO 3744:2010 |

2.3 Intelligent Control Integration

The P300 cooler integrates with FS-Elliott's R1000 control system setup featuring a 9-inch touchscreen for:

Adaptive Cooling Strategy: Dynamically adjusts bypass valve opening based on surrounding temperature (T_amb), discharge temperature (T_discharge), and cooling water flow (Q_water), keep discharge temperature within ±2℃ of setpoint.

Fault Prediction: Vibration sensors monitor tube bundle frequencies, triggering three-level alerts (warning → load reduction → shutdown) when exceeding ISO 10816-3 limits.

Energy Optimization: Historical data analysis generates optimal cooling water flow curves, reducing pump energy consumption by 15%-20% in typical operations.

3. use case Scenarios and Case Studies

3.1 Core use case Fields

Pulp & Paper Industry: provide ISO 8573-1 Class 0 oil-free air. A North American cardboard plant reported $135,000 annual maintenance cost reduction and 92% OEE after implementation.

Food & Beverage Processing: FDA-compliant design with dual-stage filtration (5μm+1μm), achieving oil content <0.003 mg/m³. A European dairy minimized microbial contamination from 0.8% to 0.03%, saving €220,000 annually in recall costs.

Electronics Manufacturing: Intelligent dehumidification keep -50℃ to -60℃ dew point. An Asian semiconductor factory increased yield from 89% to 97.5%, reducing annual losses by $1.8M.

3.2 Extreme Condition Validation

Desert use cases: keep discharge temperature below 98℃ in 52℃ surrounding conditions during 1,200-hour continuous operation at a Middle Eastern oilfield.

High-altitude Mining: Achieved 89% heat exchange overall efficiency at 4,200m elevation (61.3 kPa atmospheric pressure) in a South American copper mine through fine-tuned fin design.

4. Maintenance Strategy

4.1 Preventive Maintenance Plan

| Maintenance Item | Frequency | Procedure |

|---|---|---|

| Cooling Water Quality Check | Monthly | Test pH (6.5-8.5), conductivity (<500 μS/cm), hardness (<100 ppm CaCO₃) |

| Tube Bundle Cleaning | Quarterly | Circulate 3%-5% Kemira Chemclean 901 at 40-50℃ |

| Fin Surface Inspection | Biannually | Infrared thermography scan (investigate if ΔT >5℃) |

| Seal Replacement | Every 3 Years | Replace O-rings/gaskets with FKM or FFKM material |

4.2 Troubleshooting Guide

minimized Cooling overall efficiency: Check water flow (>80% rated), measure ΔT (8-12℃ normal), inspect fins with borescope. For scaling, use 10% citric acid; for fin damage, replace tube modules.

Water Leakage: Isolate valves, activate backup cooling, locate leak. After repair, conduct 1.5× design pressure hydrotest for 30 minutes.

4.3 Smart Maintenance Tools

FS-Elliott Insight®: Monitors 12 parameters with <8% RUL prediction error using machine learning.

AR Repair system setup: AR glasses display 3D guidance, reducing complex repair time by 40%.

5. Conclusion

The FS-Elliott Compressor Cooler P300 represents a breakthrough in industrial compressor thermal management through its straight-through cooling design, enhanced fin technology, and intelligent controls. Serving demanding industries like paper manufacturing, food processing, and electronics, the P300 cooler provide exceptional heat transfer operational performance with low maintenance requirements. As Industry 4.0 and carbon neutrality goals advance, FS-Elliott's continued innovation in digital monitoring and predictive maintenance will strengthen its leadership in premium industrial compression system setups.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsFS-Elliott Compressor Cooler P400

View Details

View DetailsFS-Elliott Compressor Cooler P600

View Details

View DetailsFS-Elliott Compressor Cooler P700

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.