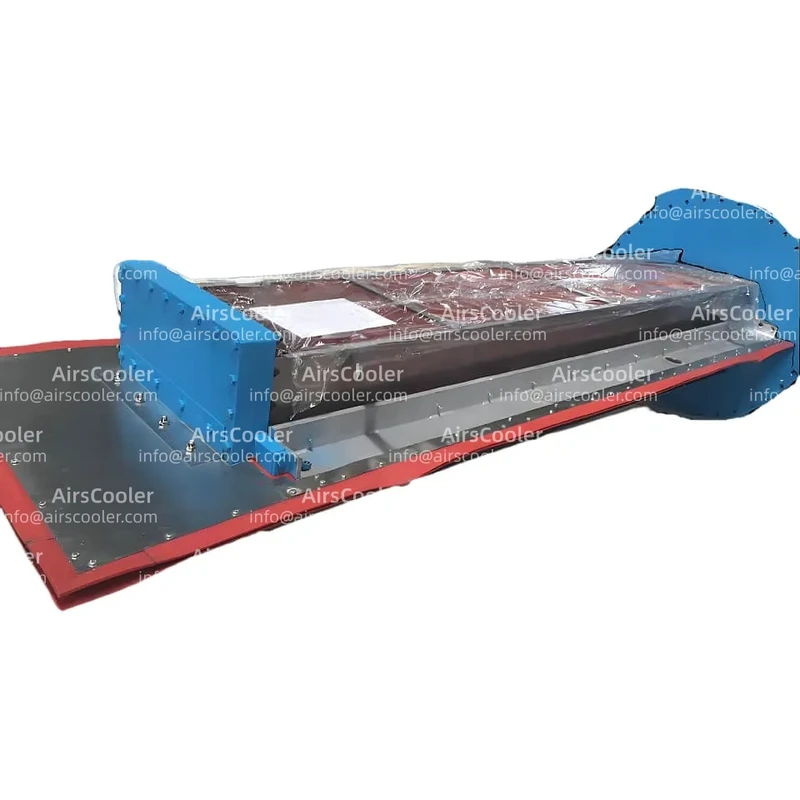

FS-Elliott Compressor Cooler P600

The FS-Elliott P600 cooler represents the pinnacle of heat exchange technology for centrifugal compression systems, delivering unmatched reliability and efficiency for critical industrial applications.

Product Overview: Precision configured Heat Exchange Technology

The FS-Elliott Compressor Cooler P600 is a high-operational performance thermal exchanger specifically built for centrifugal air compressors. As the core module of FS-Elliott's P600 series centrifugal compressors, its technological evolution draws upon the brand's century-long heritage in turbomachinery manufacturing.

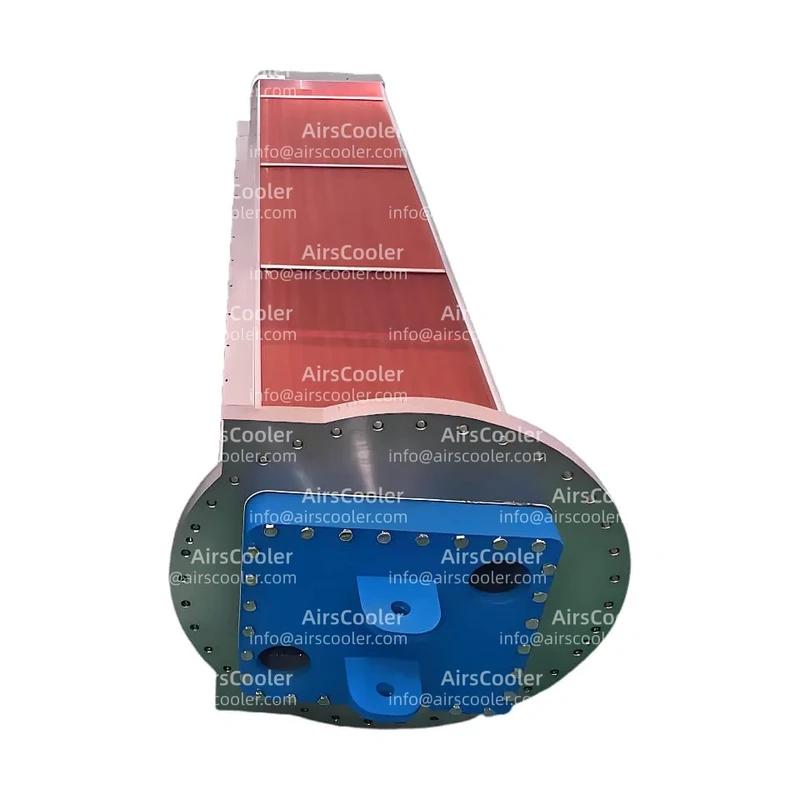

This cooler utilizes a copper tube-aluminum fin composite structure to enable forced convection heat transfer of oil-gas mixtures. Its design strictly complies with ISO 8573-1 CLASS 0 oil-free standards, ensuring zero oil contamination in compressed air system setups. The P600 cooler features modular architecture that supports thermal load matching for single-stage, two-stage, and three-stage compression conditions.

The main structure consists of copper tube bundles, hydrophilic aluminum fin assemblies, 304 stainless steel side panels, and removable covers. With copper tube inner diameter precision reaching ±0.02mm and blue wave-coated aluminum fins, it achieves 23% higher heat exchange overall efficiency compared to conventional designs. The cooler deeply integrates with FS-Elliott's R1000 intelligent control system setup, dynamically adjusting cooling water flow based on real-time monitoring of oil temperature, air pressure, and flow data to help ensure stable operation in surrounding temperatures ranging from -20°C to 50°C.

Technical Specifications & operational performance Data

| Parameter | Specification |

|---|---|

| Heat Transfer Coefficient | 1200W/m²·K (18% higher than standard coolers) |

| Water Side pressure loss | ≤0.05MPa at 15m³/h flow rate |

| Vibration Resistance | ≤2.8mm/s (ISO 10816-3 compliant) |

| Corrosion Resistance | 1000hr salt spray test passed |

| Operating Temperature Range | -20°C to 50°C surrounding |

| Design Life | ≥80,000 operational hours |

Core Technological Advantages

1. Advanced Heat Exchange system setup

Material Configuration: T2 copper tubes (tensile strength ≥205MPa) with hydrophilic corrugated aluminum fins (0.12mm thickness, 2.3mm spacing). Mechanical tube expansion creates interference fit with contact thermal resistance ≤0.0005m²·K/W.

Cooling overall efficiency: Achieves 23% higher overall efficiency than conventional designs through precision-configured copper tubes (±0.02mm tolerance) and blue wave-coated aluminum fins.

2. Corrosion Resistance & Reliability

Surface Protection: Nanoscale nickel-phosphorus plating (5-8μm) on copper tubes passes 1000hr salt spray test. Aluminum fins feature hydrophilic blue wave coating with ≤15° contact angle, improving anti-fouling operational performance by 40%.

Redundant Design: Dual-channel cooling water interfaces keep 80% cooling capacity during single-channel failures.

3. Smart Control Integration

Data Interface: Supports Modbus RTU/TCP protocols for real-time transmission of 12 parameters including oil temperature, water temperature, and flow rates.

Adaptive Control: Built-in PID algorithm dynamically adjusts cooling water flow, achieving 35% water savings during idle operation.

Predictive Maintenance: Monitors flow variations (>15%) and temperature fluctuations (±5°C/min) to provide 72-hour advance fault warnings.

Industrial use cases & Case Studies

1. Typical use case Scenarios

Petrochemical: Provides ≤40°C cooling air for hydrogen compressors in refinery hydrocracking units.

Air Separation: Cools compressed air below -180°C for liquid oxygen/nitrogen production.

Semiconductor: provide CLASS 0 oil-free air for 10nm lithography processes.

2. Retrofit Case Study: Glass Manufacturing Plant

Location: Benxi, Liaoning Province (2021)

Challenge: Two idle P600 compressors required thermal system setup upgrades for new production requirements.

offering:

- Increased copper tubes from 128 to 160, fin density from 280 to 350 fins/meter

- Integrated R1000-PLUS control system setup

- Added 316L stainless steel liner and EDI ultra-pure water system setup

Results: 22% airflow increase (180→220m³/min), 18% energy reduction, 40% lower maintenance costs.

Maintenance & Service Strategy

1. Routine Inspection

Pressure Monitoring: Daily recording of cooling water pressure (clean when ΔP>0.08MPa)

Temperature Checks: keep 50-60°C oil-water temperature difference

2. Comprehensive Maintenance

Chemical Cleaning: 18-month intervals using 10% citric acid + 0.5% inhibitor offering

Fin Maintenance: 0.3MPa air backflushing for deformed fins (>5% deformation requires replacement)

3. Spare Parts Management

Critical modules: keep 1:1.5 ratio for tube bundles, O-rings, sensors

Lifecycle Management: Ultrasonic testing every 5 years for copper tubes

Conclusion: Redefining Industrial Thermal Management

The FS-Elliott Compressor Cooler P600 represents a breakthrough in industrial thermal management through its fusion of material science, fluid dynamics, and intelligent control. With proven 30% overall efficiency gains in retrofit use cases and a 20+ year service life through proper maintenance, it provide exceptional value across demanding industries. In support of carbon neutrality goals, the P600 enables 15-20% reductions in energy consumption per unit product, establishing itself as a cornerstone technology for sustainable manufacturing.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsFS-Elliott Compressor Cooler P700

View Details

View DetailsFS-Elliott Compressor InterCooler

View Details

View DetailsFS-Elliott Compressor Oil Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.