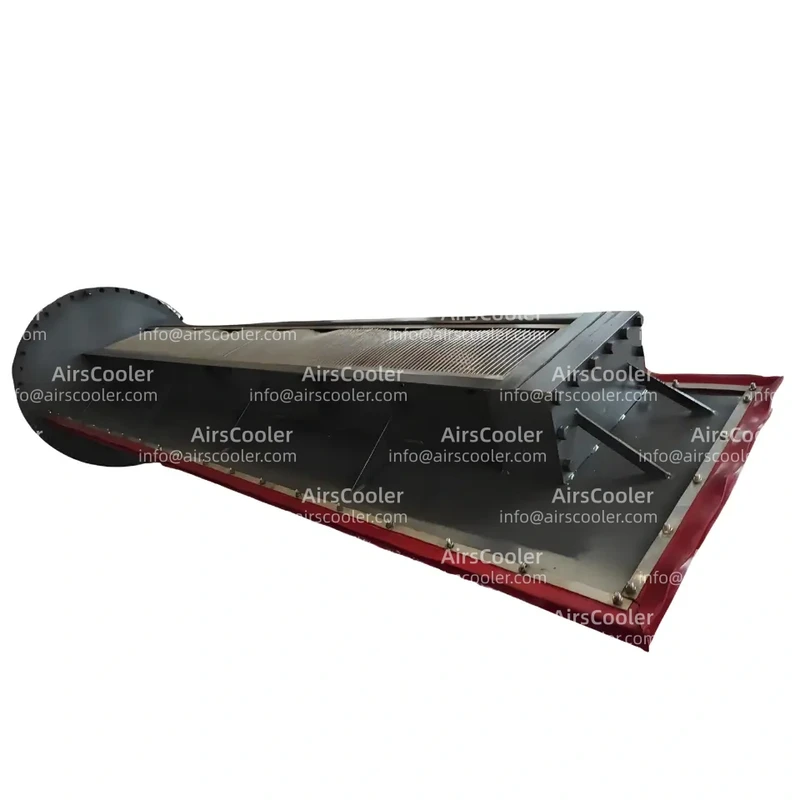

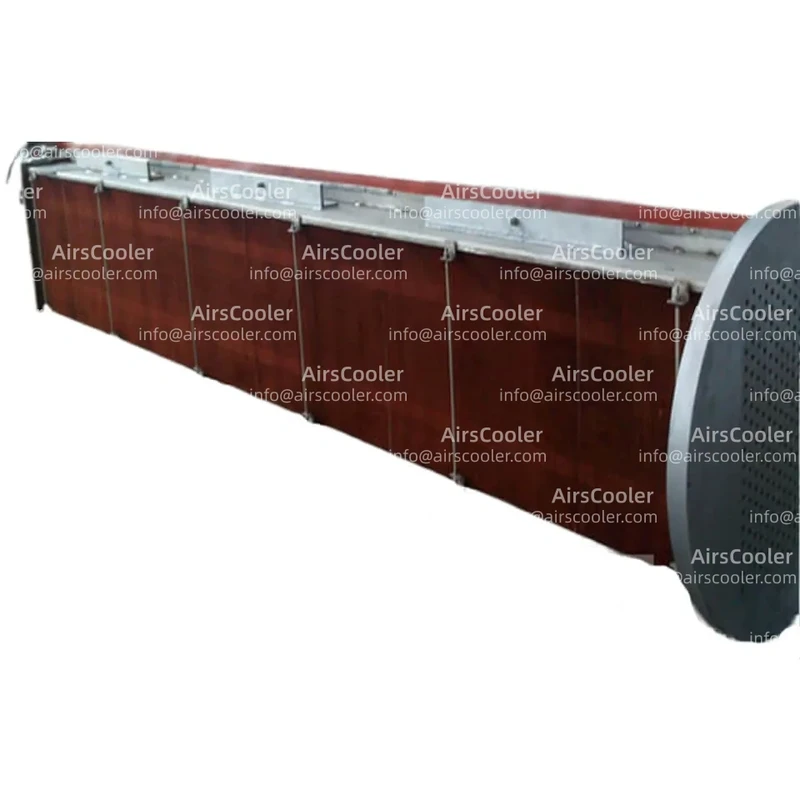

FS-Elliott Compressor Oil Cooler

The ultimate thermal management solution for centrifugal air compressor systems, delivering unmatched cooling efficiency and reliability.

1. Product Overview: Core module of Industrial Heat Exchange system setups

The FS-Elliott Compressor Oil Cooler (referred to as "FS-Elliott Oil Cooler") is an industrial-grade heat exchange device specifically built for centrifugal air compressors. Its primary function is to keep compressor oil temperature within safe operating limits through forced heat exchange, ensuring system setup stability.

1.1 Technical Evolution & Certification system setup

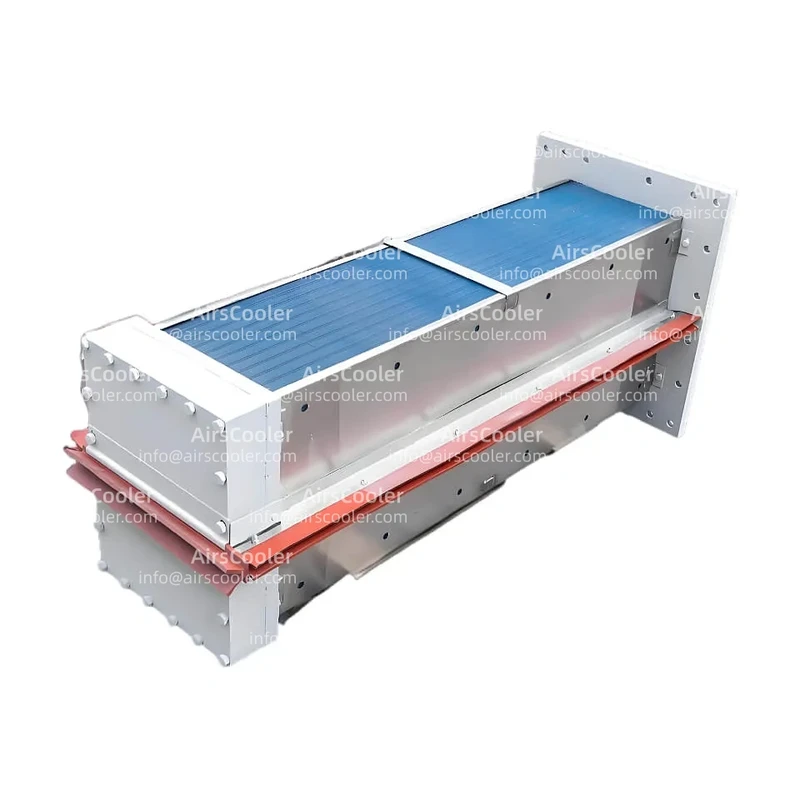

This cooler's technology originates from FS-Elliott's turbomachinery thermal management expertise dating back to its 1924 acquisition of KERR Turbine Company. The core design holds API672 certification and complies with ISO 8573-1 CLASS 0 oil-free air standards. Representative models like S0504002 incorporate patented spiral-grooved stainless steel tubes and external finned tubes through localized production at manufacturing partners like Wuxi Cooler Equipment Co., provide heat dissipation operational performance matching global top-tier brands.

1.2 system setup Architecture & Functional Modules

The cooler body consists of three-stage heat exchange units:

- Primary Cooling Module: Handles first-stage discharge high-temperature oil (up to 120°C)

- Secondary Cooling Module: Processes interstage cooling oil (85-95°C)

- Final Cooling Module: Manages third-stage discharge high-temperature oil (105-115°C)

Each module features straight-through tube design for gas-liquid separation, with self-cleaning filters capturing particles ≥0.5mm. The full-capacity auxiliary oil pump system setup keep 100% cooling capacity during main pump failures.

2. Technical Features & operational performance Data

2.1 High-overall efficiency Heat Exchange operational performance

| operational performance Metric | Parameter Range | Test Conditions |

|---|---|---|

| Cooling overall efficiency | ≥92% | Inlet oil temp 120°C/Cooling water 30°C |

| Heat Transfer Coefficient | 3,200-4,500W/(m²·K) | ANSI/ASME Standard Test |

| pressure loss Control | ≤0.08MPa (full load) | ISO 1217 Standard |

| Corrosion Resistance | 1,000hr salt spray test without rust | ASTM B117 Standard |

The spiral-grooved stainless steel tube technology increases turbulent flow by 40%, while external finned tube structure (8:1 fin ratio) expands heat dissipation area by 65% within same volume. Field data shows 18% energy savings versus conventional coolers in 3,500CFM petrochemical use cases.

2.2 Reliability Engineering

- Bearing Protection: Dual-redundant temperature sensors activate cooling fans at 110°C and trigger compressor frequency reduction at 120°C

- Freeze Protection: Gradient diversion structure keep 30% cooling capacity at -20°C surrounding temperature

- Vibration Control: Tilting-pad thrust bearings limit vibration to ≤2.5mm/s (ISO 10816 Standard)

2.3 Maintenance Optimization

- Modular Maintenance: Horizontal split gearbox design minimizes service time by 40%

- Smart Diagnostics: R1000 control system setup monitors 12 parameters (oil temp, flow, pressure loss) with 98% fault prediction accuracy Extended Cleaning Cycles: Straight-through tube design enables 8,000-hour cleaning intervals (3× longer than conventional coolers)

3. use cases & Case Studies

3.1 Core use case Sectors

- Petrochemical Industry: In refinery catalytic cracking units with FS-Elliott P700+ compressors, oil coolers demonstrated:

- 92% lubricant viscosity retention after 24 months

- 0.03mm bearing wear (within design life)

- 22% reduction in cooling water consumption

- Gas Separation: Customized coolers at 3,500m altitude achieved:

- 99.6% oxygen recovery

- 99.9995% nitrogen purity

- 4.7% of total energy consumption

- Electronics Manufacturing: Three-stage filtration in semiconductor cleanrooms keep:

- Initial oil content ≤0.003ppm

- ≤0.005ppm after 12 months continuous operation

3.2 Engineering Case Study

Project: LNG Terminal Booster system setup Retrofit

Date: 2023 Q3

Pre-Retrofit Issues:

- 35% cooling overall efficiency loss due to saltwater corrosion

- ±15°C oil temperature fluctuations

- 120 hours annual maintenance downtime

offering:

- Installed customized FS-Elliott S0504002 oil cooler

- Added 120μm dual-layer anti-corrosion coating

- Upgraded to R1000 control system setup

Results:

- Oil temperature stabilized to ±3°C

- Annual maintenance minimized to 25 hours

- 8.2% compressor overall efficiency improvement

4. Maintenance Strategies

4.1 Preventive Maintenance Program

| Maintenance Item | Interval | Procedure | Acceptance Criteria |

|---|---|---|---|

| Filter Cleaning | 2,000 hours | 0.8MPa reverse flushing | pressure loss within ±5% of initial |

| Seal Inspection | 4,000 hours | O-ring compression rate check (15-20%) | No permanent deformation |

| Coating Inspection | Annual | 15kV spark testing | No penetrating defects |

| Water Side Cleaning | 8,000 hours | 12hr inhibitor circulation | Scale thickness ≤0.1mm |

4.2 Troubleshooting Guide

High Oil Temperature:

- Verify cooling water flow (≥15L/min)

- Check fan speed (2,850rpm nominal)

- Confirm heat transfer coefficient (≥3,200W/(m²·K))

Excessive pressure loss:

- Inspect filter blockage (>60% requires replacement)

- Check tube bundle deformation (≤2mm enableed)

- Test water hardness (≤150ppm)

4.3 Spare Parts Management

Critical Spares:

- Spiral-grooved tube bundles (2 sets per lifecycle)

- Tilting-pad bearings (1 year inventory)

- Seal gasket kits (1:1.5 ratio)

Inventory Model: ABC classification with VMI for 70% high-value (A) items, safety stock + dynamic replenishment for B/C items.

5. Conclusion & Future Development

The FS-Elliott Compressor Oil Cooler integrates century-old turbomachinery thermal expertise with modern engineering to provide a three-dimensional technical system setup encompassing overall efficiency, reliability, and maintainability. Typical use cases achieve 25,000+ hours MTBF and 35% annual maintenance cost reduction. Industry 4.0 advancements will focus on:

- Digital Twin: IoT-enabled real-time operational performance modeling

- Advanced Materials: Nano-coatings for 15+ year service life

- Smart Algorithms: Machine learning for adaptive flow control

As energy transition and smart manufacturing advance, FS-Elliott oil coolers will continue providing superior thermal management offerings, supporting global industry's transition toward low-carbon, intelligent operations.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsFS-Elliott Compressor Cooler P500

View Details

View DetailsCooper Joy Compressor AfterCooler

View Details

View DetailsCooper Joy Compressor Cooler TA11000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.