FS-Elliott Compressor Cooler P500

The comprehensive technical reference for industrial cooling system professionals

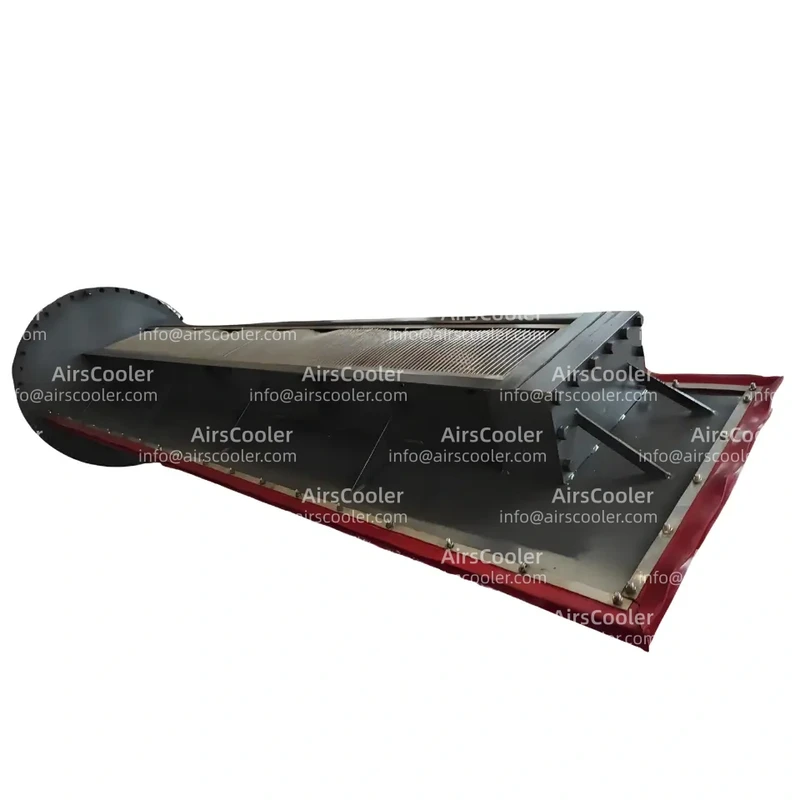

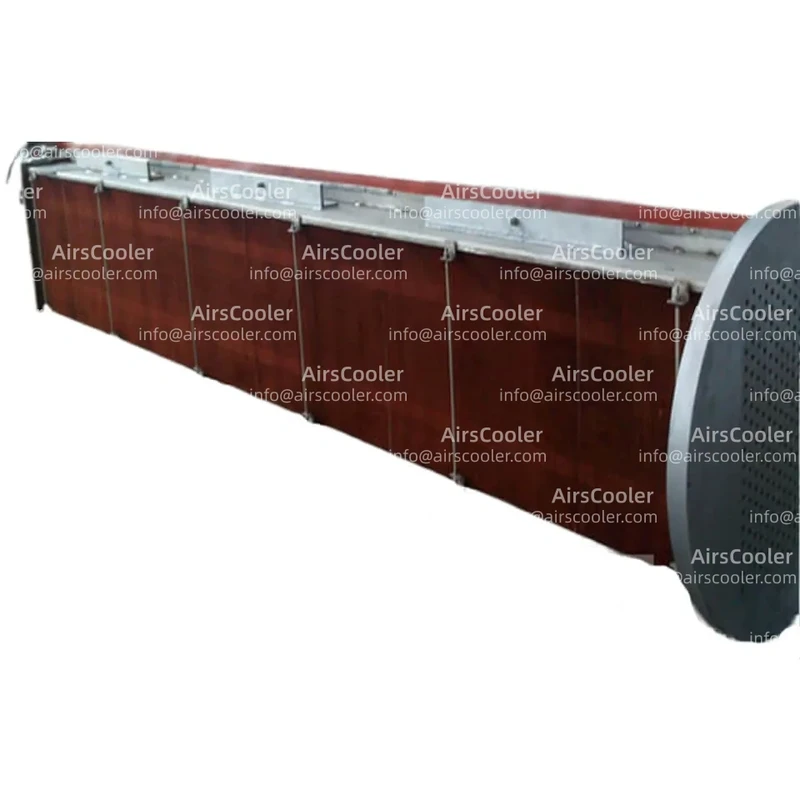

1. Product Overview: Core module of Centrifugal Air Compressor Cooling system setups

The FS-Elliott Compressor Cooler P500 is an industrial-grade cooling device specifically built for centrifugal air compressors. As the core module of the compressor's thermal management system setup, its operational performance directly affects the compressor's operational overall efficiency, stability, and service life. This cooler features modular design, compatible with FS-Elliott P-series centrifugal compressors (including P300/400/500/700 models), utilizing advanced heat exchange technology to transfer heat generated during compression to cooling media (water or air), ensuring the compressor operates within the safe temperature range below 90°C.

Technical Positioning and Industry Value

- Energy overall efficiency Improvement: In high-precision manufacturing sectors like semiconductors, chemicals, and food & beverage, the P500 cooler keep compressor temperature stability, ensuring gas purity and flow consistency, thereby indirectly improving production yield. For semiconductor manufacturing where oil-free compressed air requires extreme purity, the cooler must keep exhaust temperatures below 110°C to prevent lubricant decomposition from contaminating the air stream.

- Reliability and Maintenance Cost Optimization: Constructed with corrosion-resistant stainless steel and spiral-grooved tube technology, the cooler withstands industrial chemical corrosion and high-pressure impacts, minimizing downtime from cooling system setup failures. User reports indicate that after 3,000 continuous operation hours, the P500 cooler shows less than 5% heat exchange overall efficiency degradation - significantly better than industry averages.

- Compatibility and Scalability: Supports air-cooled, water-cooled, and hybrid cooling modes for flexible configuration. In water-scarce regions, air-cooled modules can be deployed, while water-cooled system setups can be added for use cases requiring higher heat exchange overall efficiency.

2. Technical Features and operational performance Data

1. Heat Exchange operational performance Parameters

- Cooling overall efficiency: The spiral-groove stainless steel tube technology increases heat transfer surface area by 40% compared to conventional smooth tubes, reducing cooling water flow requirements by 25% under identical conditions.

- Temperature Control Precision: Integrated smart temperature control module keep ±1°C accuracy, adaptable to various compressor exhaust temperature ranges (60-130°C).

- Pressure Tolerance: Constructed with SAE 316L stainless steel, the cooler withstands 1.6MPa working pressure for high-pressure use cases.

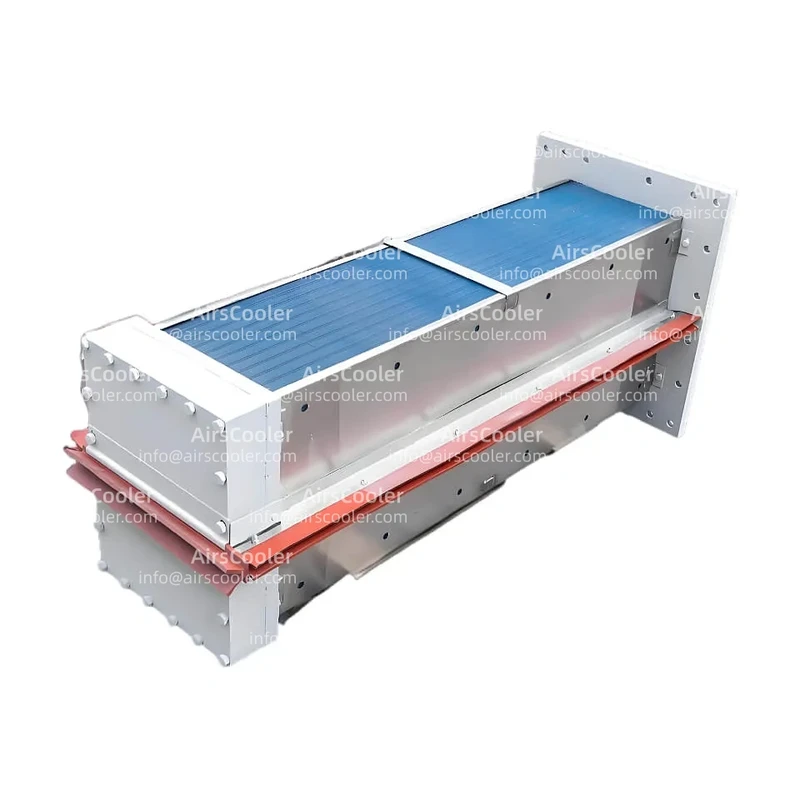

2. Structural and Material Innovations

- Spiral Groove Tube Technology: Internal spiral grooves increase fluid turbulence, improving heat transfer coefficient by 30% compared to smooth tubes.

- Counterflow Design: Cooling medium and compressed air flow in opposite directions to maximize temperature differential utilization while minimizing scaling risks.

- Modular Construction: Composed of multiple independent modules that can be quickly replaced individually, reducing repair time by 70% compared to conventional single-unit designs.

3. Intelligent Monitoring and Protection

- Multi-parameter Sensors: Integrated pressure, temperature, and flow sensors provide real-time monitoring, transmitting data via RS485 or Modbus protocols to control system setups.

- Three-stage Protection:

- Primary Warning: Triggers audible/visual alarms when cooling water flow drops below 3L/min

- Secondary Load Reduction: Automatically minimizes compressor load when exhaust temperature exceeds 120°C

- Emergency Shutdown: Forces shutdown when cooling water pressure falls below 0.2MPa or temperature exceeds 130°C

4. operational performance Comparison

| Parameter | P500 Cooler | Industry Average | Improvement |

|---|---|---|---|

| Heat Exchange overall efficiency | 92% | 85% | +8.2% |

| Maximum Working Pressure | 1.6MPa | 1.2MPa | +33% |

| Mean Time Between Failures | 80,000 hours | 50,000 hours | +60% |

| Annual Maintenance Cost | $1,200 | $2,500 | -52% |

3. use case Scenarios and Case Studies

1. Semiconductor Manufacturing

Requirements: Wafer fabrication processes require oil-free compressed air for vacuum pumps with dew points below -40°C. The P500 cooler's precise temperature control prevents condensate condensate formation from contaminating wafer surfaces.

Case Study: A 12-inch wafer fab implemented P500 coolers, reducing compressed air oil content from 0.01ppm to 0.003ppm, decreasing equipment downtime by 40%, and saving approximately $80,000 annually in maintenance costs.

2. Chemical Industry

Requirements: Ammonia synthesis plants require compressors running 2,000 hours annually with coolers resistant to high pressure/temperature and ammonia corrosion. The P500's duplex stainless steel construction keep overall efficiency in pH 2-12 environments.

Case Study: A fertilizer plant minimized compressor exhaust temperatures from 140°C to 110°C using P500 coolers, saving 1.2 million kWh annually and extending equipment lifespan to 15 years.

3. Food and Beverage Industry

Requirements: Aseptic filling lines require compressed air meeting ISO 8573-1 Class 0 standards, demanding coolers that prevent oil and microbial contamination. The P500's fully enclosed water circuit eliminates leakage risks.

Case Study: A dairy producer minimized product microbial rejection rates from 0.5% to 0.02% after installing P500 coolers, cutting $200,000 in annual recall costs.

4. Maintenance Strategies

1. Routine Inspection Checklist

- Cooling Water system setup:

- Verify flow rate (≥3L/min) and pressure (0.2-0.6MPa)

- Monitor water pH (6.5-8.5) and perform regular drainage

- Clean cooling tower fill to prevent algae growth

- Cooler Unit:

- Check for fin debris accumulation (monthly)

- Confirm fan operation (≥1200rpm)

- Calibrate temperature sensors (biannually)

2. Scheduled Maintenance Plan

| Interval | Maintenance Task | Standard |

|---|---|---|

| Quarterly | Clean surface oil/debris | Use neutral detergent, pressure ≤0.3MPa |

| Biannually | Replace water filter elements | Replace when pressure differential ≥0.1MPa |

| Annually | Inspect internal corrosion | Ultrasonic testing, wall thickness ≥2.5mm |

| 3 Years | Replace seals and bearings | Leakage ≤0.1mL/min |

3. Troubleshooting Guide

- High Exhaust Temperature:

- Check for insufficient cooling water flow

- Inspect for clogged fins

- Verify temperature sensor functionality

- Water Leakage:

- Immediately shutdown and close water valves

- Inspect seal ring deterioration

- Replace damaged O-rings

- Fan Failure:

- Check for motor overload

- Clean fan blade accumulation

- Test control circuitry

5. Conclusion: FS-Elliott P500 Cooler's Technical Advantages

The FS-Elliott Compressor Cooler P500 provide superior heat dissipation, low maintenance costs, and exceptional reliability through its spiral groove tube technology, counterflow design, and intelligent monitoring. Across semiconductor, chemical, and food processing industries, its implementation enhances production overall efficiency and product quality while reducing energy consumption and operational expenses. More than just hardware, the P500 represents a complete thermal management offering. As Industry 4.0 and smart manufacturing evolve, the P500 cooler will incorporate IoT capabilities for remote monitoring and predictive maintenance, driving industrial cooling technology toward intelligent, low-carbon offerings.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Joy Compressor AfterCooler

View Details

View DetailsCooper Joy Compressor Cooler TA11000

View Details

View DetailsCooper Joy Compressor Cooler TA18

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.