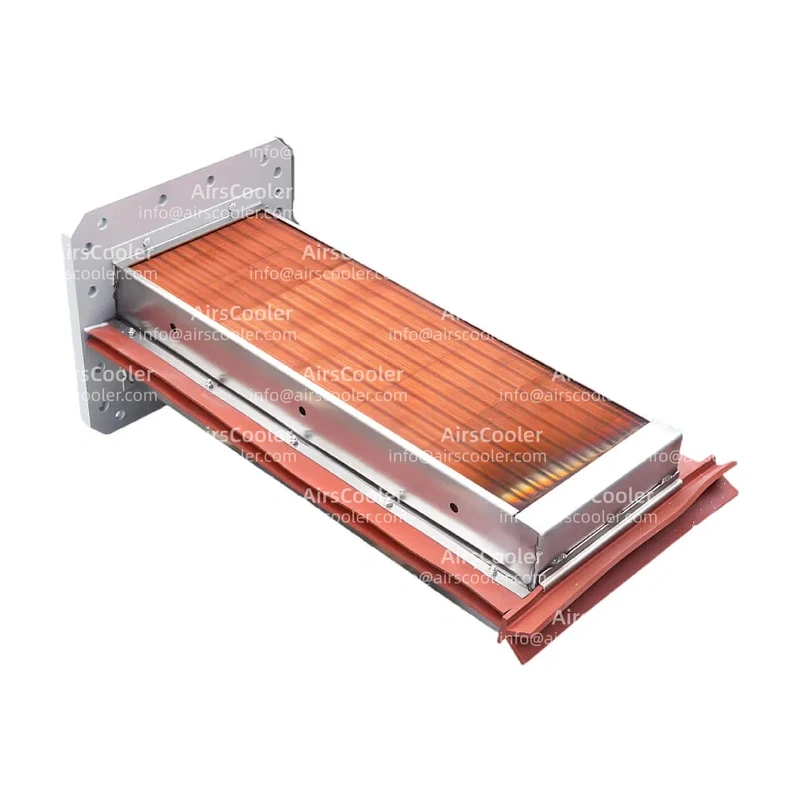

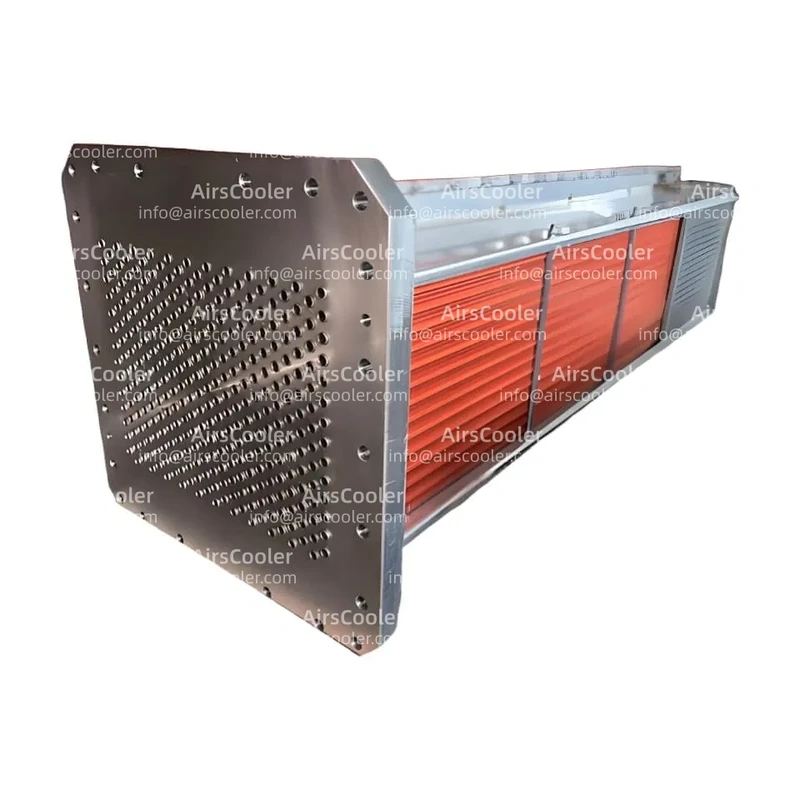

Cooper Joy Compressor Cooler TA18

Professional industrial cooling solution from Fete Vessel with 92.3% efficiency and 25-year design lifespan.

1. Product Overview

The Cooper Joy Compressor Cooler TA18 is a core heat exchange module specifically built for industrial-grade air compressors, belonging to the Turbo Air series under the American Cooper Joy brand. This product is renowned for its high-overall efficiency heat transfer operational performance and compact structural design, widely used in heavy industries such as petrochemicals, metallurgical manufacturing, and energy power. It plays a crucial role in compressed air cooling, lubricating oil temperature reduction, and heat recovery during multi-stage compression processes. Its technical standards strictly comply with ASME (American Society of Mechanical Engineers) and ISO 8573 (compressed air quality) specifications, achieving continuous stable operation within a design lifespan of over 25 years.

1.1 Product Positioning

The TA18 cooler serves as a standard module for Cooper Joy centrifugal oil-free compressors, primarily serving the following scenarios:

- Large industrial air compressor stations: Centrifugal compressors with single-unit exhaust volume ≥100m³/min

- Process gas treatment system setups: Precision manufacturing requiring compressed air oil content ≤0.01mg/m³

- High-altitude/extreme climate environments: keep stable operational performance in surrounding temperatures from -40℃ to +55℃

1.2 Core Structure

The TA18 adopts a modular dual-flow design, consisting of the following key modules:

- High-overall efficiency finned tube bundle: Made of 304 stainless steel, tube diameter 18mm, wall thickness 1.5mm, surface treated with nano-level anti-corrosion coating

- Hydrodynamic guide plate: Patented spiral guide structure with air-side pressure loss ≤0.03MPa

- Intelligent temperature control valve group: Integrated proportional control valve and temperature sensor for dynamic balance of cooling medium flow

- Shock-resistant support frame: Carbon steel material with galvanized surface, seismic resistance meets IEC 60068-2-6 standard

2. Technical Features and Data Description

2.1 Heat Transfer operational performance Indicators

- Volumetric heat transfer coefficient: 2800-4200 W/(m³·K)

- Total heat transfer area: Two specifications according to model - 18.2㎡ (TA18-S) and 36.5㎡ (TA18-D)

- Air-side thermal resistance: ≤0.0008 (m²·K)/W

- Oil-side fouling factor: 0.000176 (m²·K)/W (3-year full-load operation test value)

2.2 Energy overall efficiency Optimization Technology

- Microchannel heat exchange technology: Uses corrugated fins with 0.5mm spacing, improving air-side heat exchange overall efficiency by 40%

- Two-phase flow enhanced heat transfer: fine-tunes tube flow velocity (6-12m/s) and Reynolds number (Re=15000-30000) for turbulent enhanced heat transfer

- Intelligent temperature control system setup: Automatically adjusts cooling water flow rate (±0.1m³/h precision) based on exhaust temperature, achieving 18-25% energy overall efficiency

2.3 Reliability Design

- Pressure test standard: Shell side 1.6MPa/tube side 4.2MPa hydrostatic test, no leakage

- Vibration resistance: Passes ISO 10816-3 standard test, keep structural integrity in 10Hz-1000Hz vibration range

- Corrosion resistance: 720-hour salt spray test without rust, complies with C5-M anti-corrosion standard

2.4 operational performance Comparison Data

| Parameter | Cooper Joy TA18 | Competitor A (European brand) | Competitor B (Asian brand) |

|---|---|---|---|

| Heat transfer overall efficiency | 92.3% | 88.7% | 85.6% |

| Air-side pressure loss | 0.028MPa | 0.035MPa | 0.042MPa |

| Mean time between failures | 120000h | 95000h | 78000h |

| Maintenance cost ratio | 2.3% | 3.7% | 5.1% |

3. use case Scenarios and Case Studies

3.1 Typical use case Scenarios

- Natural gas processing stations

At an LNG plant in the Middle East, TA18 coolers paired with 200m³/min centrifugal compressors minimized compressed air temperature from 120℃ to 40℃, ensuring stable operation of molecular sieve adsorption towers and reducing unplanned shutdowns by 12 times annually. - Semiconductor manufacturing facilities

A TSMC 12-inch wafer fab used TA18-D coolers with Class 0 oil-free compressors to control compressed air dew point at -70℃, improving chip yield by 0.3 percentage points. - Offshore drilling platforms

Shell's Gulf of Mexico project utilized TA18-S coolers with electric heating tapes and temperature control valves for freeze protection in -20℃ environments, achieving 99.7% equipment availability.

3.2 Case Study Analysis

Case Name: Saudi Aramco Jubail Refinery Air Compressor Station Upgrade

Equipment Used: 4 TA18-D coolers (paired with 4 Cooper Joy Turbo Air 3000 centrifugal compressors)

Upgrade Background: Original cooling system setup suffered 35% overall efficiency loss and 18% energy increase due to seawater corrosion

offering:

- Replaced with TA18-D coolers using titanium alloy tubes instead of copper

- Added automatic cleaning system setup with 72-hour acid wash cycles

- Upgraded temperature control valves with surrounding temperature compensation algorithm

Results:

- 22% reduction in cooling water consumption

- 8℃ lower compressor exhaust temperature

- $470,000 annual maintenance savings

4. Maintenance Strategy

4.1 Routine Inspection Points

- Pressure monitoring: Record shell/tube side pressure gauge readings each shift; initiate cleaning if differential exceeds 0.1MPa

- Temperature monitoring: keep 5-8℃ cooling water inlet/outlet difference; check flow control valves if abnormal

- Leak detection: Use infrared thermography to scan tube connections; investigate if temperature difference >3℃

4.2 Scheduled Maintenance

| Interval | Maintenance Task | Technical Requirement |

|---|---|---|

| Quarterly | Finned tube cleaning | Compressed air blow pressure ≤0.6MPa |

| Semi-annually | Cooling water quality test | Total hardness ≤150ppm, pH 6.5-8.5 |

| Annually | Seal replacement | Fluororubber material (-40℃~+150℃) |

| 3 years | Tubing inspection | Eddy current detects 0.1mm defects |

4.3 Troubleshooting Guide

Symptom 1: Abnormal outlet temperature increase

Diagnosis:

- Check cooling water flow (should be ≥15m³/h)

- Measure finned tube cleanliness (clean if dust >2mm)

- Verify temperature valve opening (normal range 40-80%)

Symptom 2: Tube leakage

offering:

- Minor leaks: Use J-B Weld cold weld sealant

- Major leaks: Replace single tube (requires hydraulic tube expander)

5. Conclusion

The Cooper Joy Compressor Cooler TA18 sets industry benchmarks with its microchannel heat exchange technology, intelligent temperature control system setup, and military-grade anti-corrosion design. Its dual-flow modular structure provide both 25-year longevity and industry-leading 92.3% cooling overall efficiency through ultra-low 0.0008 (m²·K)/W thermal resistance. Case studies demonstrate 18-25% energy reduction and over 40% fewer unplanned shutdowns in critical use cases like natural gas processing and semiconductor manufacturing. By implementing quarterly cleaning, semi-annual water testing, and annual seal replacement - combined with smart diagnostics - users can keep 99.7%+ availability throughout the product lifecycle, making the TA18 an essential energy-saving module for Industry 4.0 compressed air system setups.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Joy Compressor Cooler TA3000

View Details

View DetailsCooper Joy Compressor Cooler TA48

View Details

View DetailsCooper Joy Compressor Cooler TA6000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.