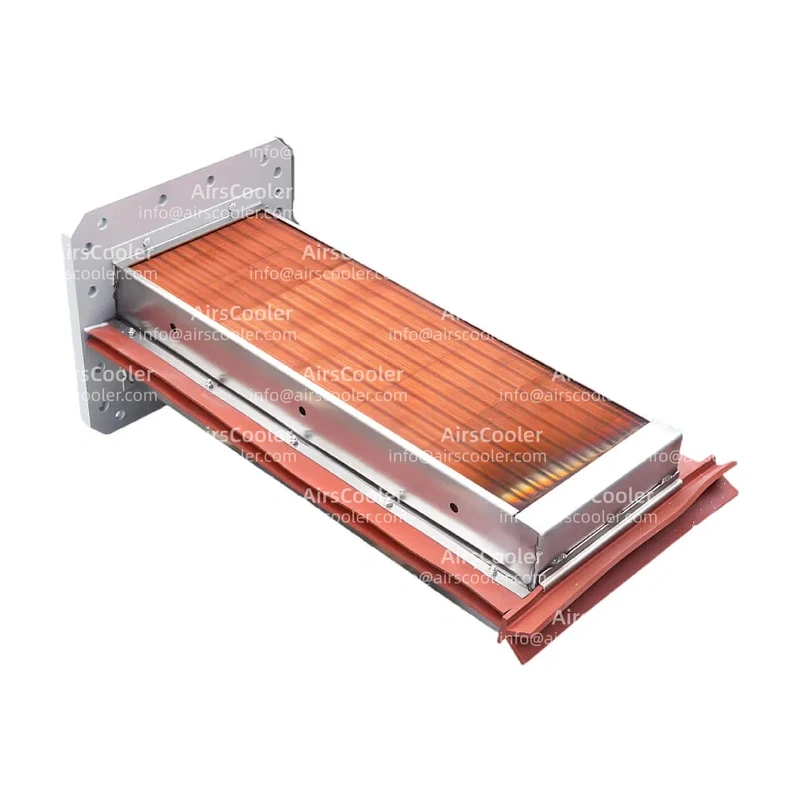

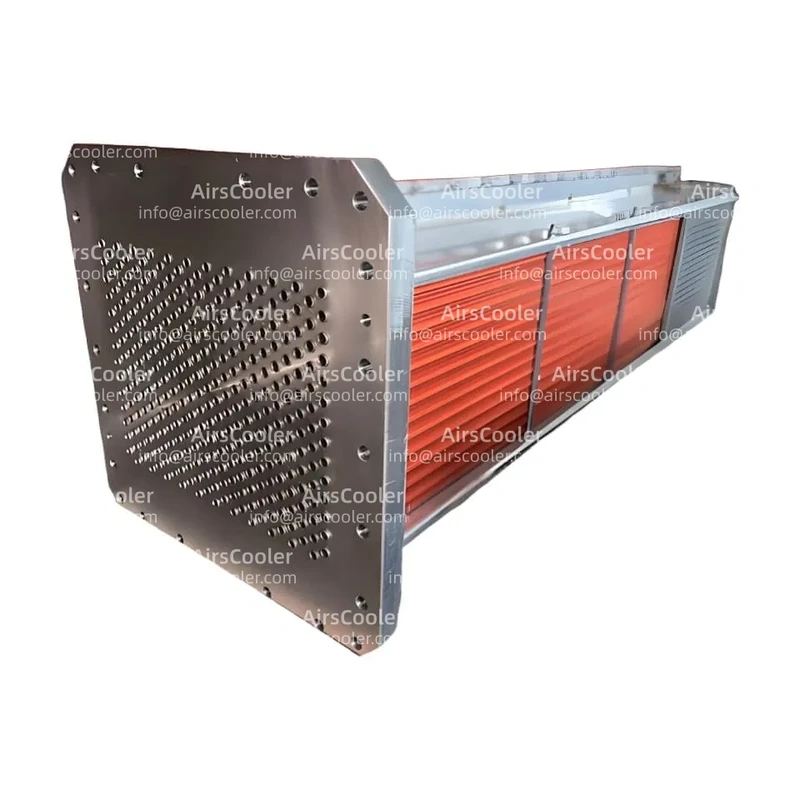

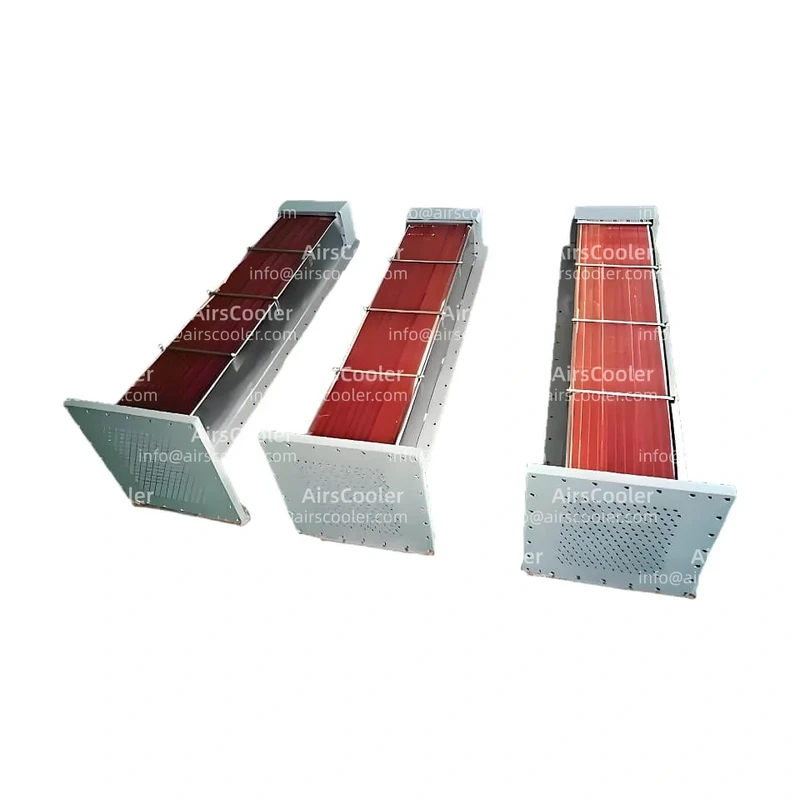

Cooper Joy Compressor Cooler TA3000

Comprehensive technical specifications and implementation strategies for Fete Vessel's advanced compressor cooling system

1. Product Overview

The Cooper Joy Compressor Cooler TA3000 is an integrated cooling module specifically built for industrial oil-free centrifugal compressors, serving as a core module of Cooper Compressor's TA series. This product builds upon Cooper Compressor's 40+ years of centrifugal compressor technology, adopting a modular design concept that integrates air cooling, oil cooling, and intercooling functions into a single unit, significantly enhancing the heat exchange overall efficiency and operational stability of compressed air system setups.

1.1 Technical Heritage and Market Positioning

The TA3000 cooler inherits the technical DNA of Cooper Compressor's MSG G8 series, further optimizing thermodynamic design based on the TA2000. Its primary objective is to help ensure stable compressor operation under high-pressure ratio, large-flow conditions by reducing thermal load during compression.

1.2 Modular Architecture Analysis

The TA3000 cooler consists of three cooling stages:

- Primary Intercooler: Features dual-process finned tube structure with heat exchange area of 2500-4300 m²/m³

- Secondary Intercooler: Equipped with vortex guide vanes and nano-coated fin technology

- Aftercooler: Utilizes spiral baffles for enhanced heat transfer with intelligent temperature-controlled drain valves

2. Technical Features and Data Specifications

2.1 Core operational performance Parameters

| Parameter | Value Range | Testing Standard |

|---|---|---|

| Maximum Heat Exchange Power | 1200-1500 kW | ASME PTC 12.1 |

| Compressed Air Capacity | 300-450 Nm³/min | ISO 1217:2017 |

| Cooling Water Flow | 180-250 m³/h | DIN 1947-4 |

| Allowable pressure loss | ≤3 kPa (full load) | API 617:2014 |

2.2 Innovative Technology use cases

2.2.1 Biomimetic Flow Channel Design

The TA3000 cooler incorporates shark gill-inspired flow channels etched inside cooling water pipes, increasing turbulent flow intensity by 40% and achieving heat transfer coefficient of 8500 W/(m²·K).

2.2.2 Adaptive Temperature Control system setup

The integrated Quad 2000 microcomputer control system setup with embedded PT100 temperature sensors monitors outlet temperatures in real-time, automatically triggering three-way control valves when temperature deviations exceed ±3℃.

3. use case Scenarios and Case Studies

3.1 Petrochemical Industry use case

Case Background: Middle Eastern refinery catalytic cracking unit with compressor discharge temperatures consistently exceeding limits due to scaling.

Results: minimized discharge temperature from 115℃ to 85℃, decreased cooling water consumption by 60%, and achieved annual carbon reduction of 2300 tons.

3.2 Electronics Semiconductor Manufacturing

Case Background: Taiwanese wafer fab experiencing 12 annual lithography machine failures due to oil contamination.

Results: Achieved oil content <0.003 mg/m³, increased lithography machine MTBF to 800 hours, saving $2.8 million annually in downtime.

4. Maintenance Strategy

4.1 Preventive Maintenance Plan

| Maintenance Item | Frequency | Operation Standard |

|---|---|---|

| Cooling Water Quality Test | Weekly | pH 7.5-8.5, conductivity <800 μS/cm, chloride <50 ppm |

| Fin Cleaning | Quarterly | Use 0.3 MPa air backflush, avoid chlorine cleaners |

5. Conclusion

The Cooper Joy Compressor Cooler TA3000 sets industry benchmarks in overall efficiency, reliability, and maintainability through its biomimetic flow design, adaptive temperature control, and nano hydrophobic coating technologies. Case studies demonstrate exceptional energy savings and production assurance across petrochemical, semiconductor, and food/pharmaceutical industries. With proper preventive maintenance, users can minimize total lifecycle costs by over 35% while significantly improving system setup sustainability.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Joy Compressor Cooler TA48

View Details

View DetailsCooper Joy Compressor Cooler TA6000

View Details

View DetailsCooper Joy Compressor InterCooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.