Cooper Joy Compressor Cooler TA6000

Comprehensive technical specifications and application solutions for industrial-grade cooling systems by Fete Vessel

1. Product Overview: Core module of Industrial Cooling offerings

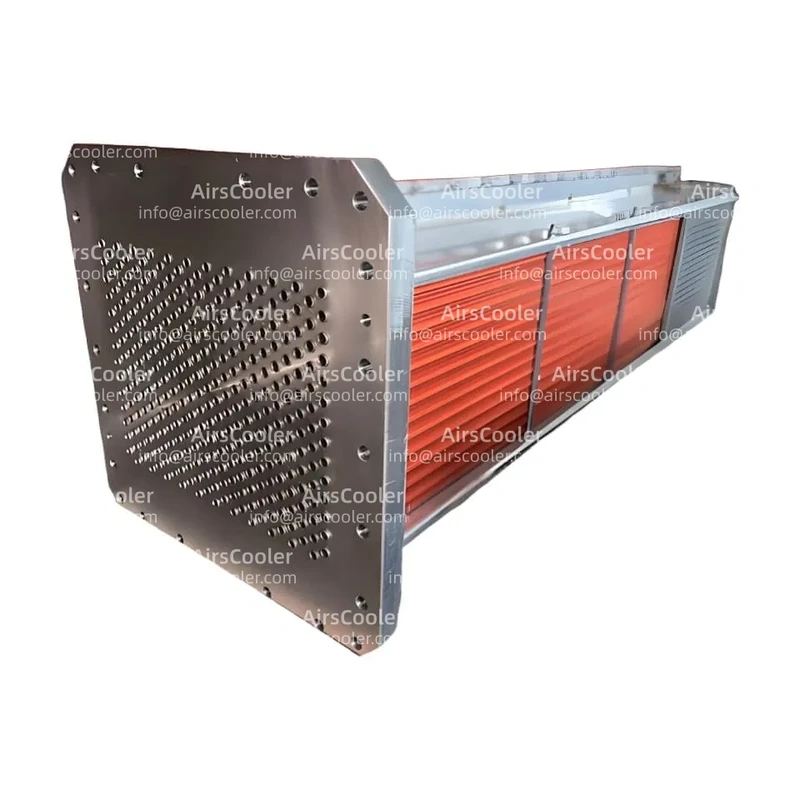

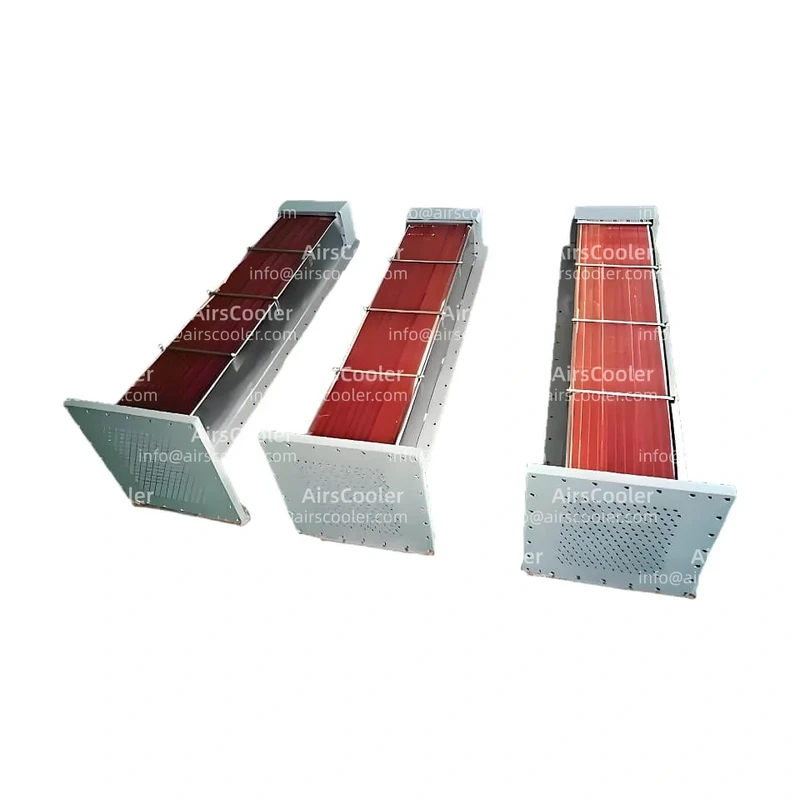

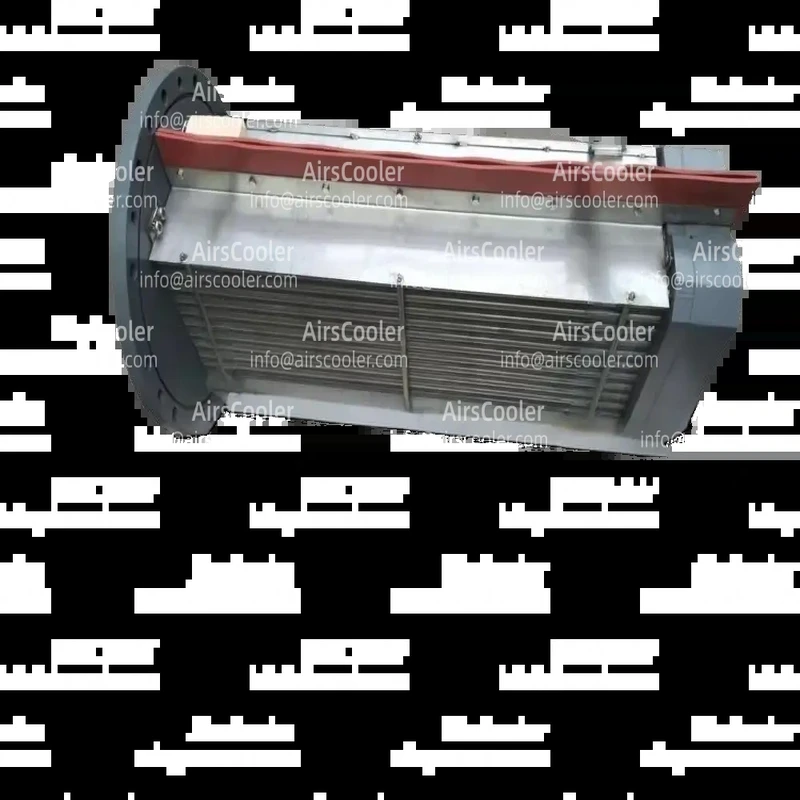

The Cooper Joy Compressor Cooler TA6000 is a heat exchange device specifically built for centrifugal oil-free air compressors, serving as a critical module of the Cameron-Cooper-Joy TA series products from AirsCooler. This cooler achieves efficient temperature reduction during multi-stage compression through fine-tuned fluid dynamics design and material technology, ensuring stable operation under rated conditions.

Key Features:

- Integrated Multi-stage Cooling Modules: Includes intercooler, aftercooler, and oil cooler to form a complete heat exchange chain

- Compact Structure Design: Single-layer layout minimizes footprint by 30% compared to traditional equipment

- Oil-free Environment Compatibility: Fully enclosed finned tube structure prevents lubricant contamination, complying with ISO 8573-1 Class 0 oil-free standard

2. Technical Specifications and Data Analysis

(1) Core operational performance Parameters

| Technical Parameter | TA6000 Cooler Specification | Industry Standard Comparison |

|---|---|---|

| Heat Exchange Area | 3,800-4,300 m²/m³ (typical model) | Conventional equipment: 1,800-2,500 m²/m³ |

| Heat Transfer Coefficient | 2,800-3,200 W/(m²·K) | Conventional equipment: 1,500-2,200 W/(m²·K) |

| Maximum Working Pressure | Up to 16 bar (gauge pressure) | Conventional equipment: ≤10 bar |

| Temperature Range | -40℃ to +200℃ (continuous operation) | Conventional equipment: -20℃ to +150℃ |

| Corrosion Protection | Electrogalvanized + epoxy resin dual-layer (ASTM B633) | Single-layer electrogalvanized protection |

(2) Innovative Structural Design

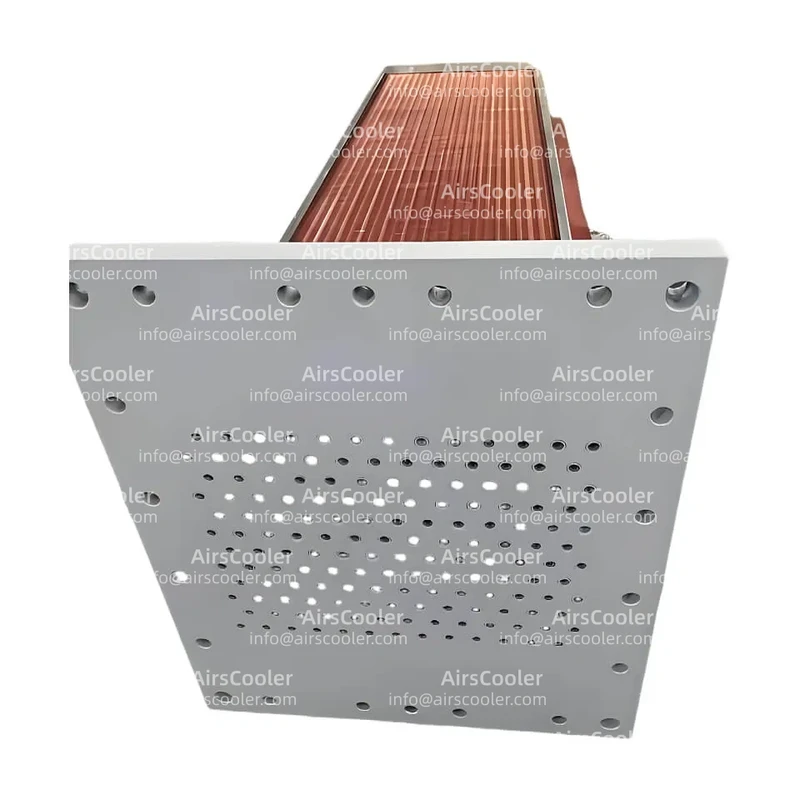

- Asymmetric Fin Matrix: Patented gradient fin arrangement with 12 fins/inch at front section and 8 fins/inch at rear section, reducing pressure loss by 12% compared to uniform fin structures

- CFD-fine-tuned Fluid Dynamics: Optimal tube spacing (1.2×tube diameter) and baffle angle (30°) keep Reynolds number (Re) at 10,000-15,000 for turbulent heat transfer

- Material Durability: SA-213 TP304L stainless steel tubes withstand 25 bar transient pressure, AL1050-H14 aluminum fins with ≥15μm anodized layer pass 1,000-hour salt spray test

3. use case Scenarios and Case Studies

(1) Typical use cases

- Petrochemical Industry: Provides -40℃ dew point air for refinery catalytic cracking units, reducing failure rate from 12 to 1 incident/year

- Semiconductor Manufacturing: provide Class 1 clean air for lithography equipment with ≤0.1μm/m³ particulates and <0.003 mg/m³ oil vapor

- Medical Gas Supply: keep medical air below 35℃ in hospital oxygen system setups, achieving 18% energy reduction

(2) operational performance Validation Case

Project: LNG terminal requiring -162℃ cryogenic operation

offering: Customized TA6000 with duplex stainless steel (S32750) tubes and glycol auxiliary cooling

Results: 18-month continuous operation with -70℃ dew point, 40% less refrigerant, 22% lower annual costs

4. Maintenance Strategy

(1) Preventive Maintenance system setup

- Three-level Inspection: Daily (surface temp ≤60℃), monthly (IR thermography), annual (fin damage ≤5%)

- Smart Monitoring: Real-time tracking of water flow (±5%), pressure loss (alert at 0.04 bar), and annual overall efficiency decay (≤2%)

(2) Troubleshooting Guide

| Symptom | Possible Cause | offering |

|---|---|---|

| High outlet temperature | Insufficient coolant/blocked fins | Clean filters/high-pressure fin wash |

| Abnormal pressure loss | Fouling/fin deformation | Chemical cleaning (5% citric acid)/part replacement |

5. Conclusion: Technological Advancement and Industry Value

The TA6000 Cooler redefines industrial compressor thermal management standards through material innovation and structural optimization, provide:

- 15-20% higher energy overall efficiency versus conventional system setups

- 120,000-hour MTBF for minimized unplanned downtime

- 40% lower maintenance costs with 25% higher residual value

As Industry 4.0 advances, TA6000 integrates with digital twin technology for predictive maintenance, setting new benchmarks for energy-intensive industries.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Joy Compressor InterCooler

View Details

View DetailsCooper Joy Compressor Oil Cooler

View Details

View DetailsIHI Compressor Air Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.