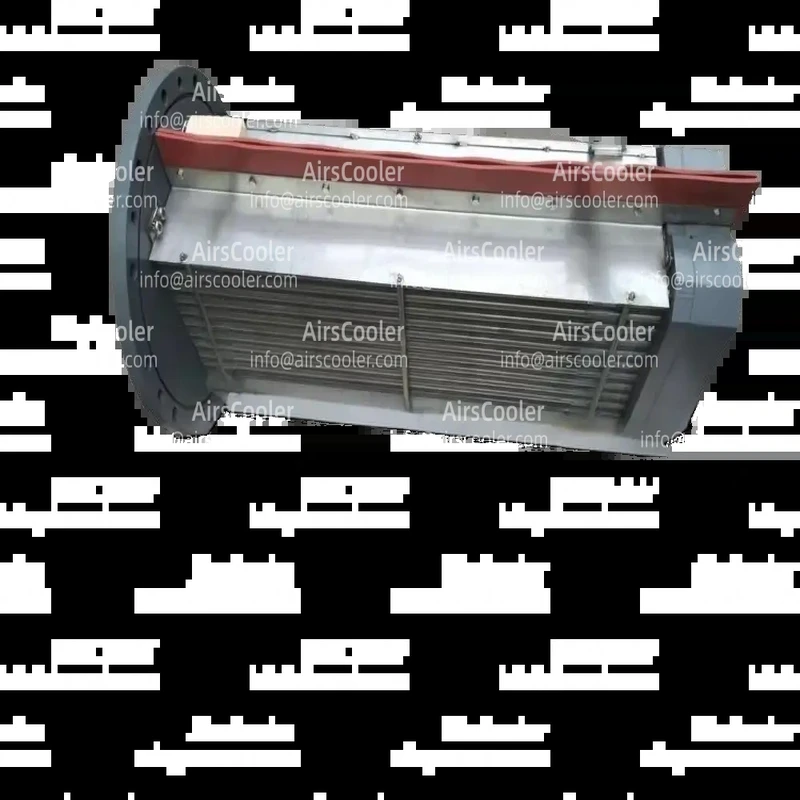

IHI Compressor Air Cooler

Advanced cooling technology for industrial air compressor systems

1. Product Overview: The Thermal Management offering for Air Compressor system setups

The IHI Compressor Air Cooler (hereafter referred to as IHI Air Compressor Cooler) is a heat exchange device specifically built for industrial-grade air compressors. Its core function is to cool high-temperature, high-pressure gas generated during compression to process-required temperature ranges through heat conduction and convection principles.

1.1 Structural Composition and Working Principle

The IHI Air Compressor Cooler features modular design with key modules including:

- Shell-and-tube thermal exchanger: High-overall efficiency heat exchange unit with copper alloy tube bundles and aluminum fins, using counter-flow design (gas through shell side, water through tube side) that enhances heat transfer efficiency by over 30%

- Intelligent temperature control system setup: Integrated pressure sensors, temperature monitoring modules and PLC controller enable real-time cooling water flow adjustment with ±1℃ temperature control accuracy

- Anti-corrosion coating: Fluorocarbon coating + titanium alloy impeller composite protection system setup for petrochemical use cases, meeting ISO 12944-2 C5-M corrosion resistance standard

1.2 Technological Evolution and Industry Positioning

From early air-cooled models to current water-air hybrid cooling system setups, IHI's continuous innovation addresses industry challenges like scaling and heat dissipation overall efficiency degradation in high-temperature, high-humidity environments. The latest generation product fine-tunes tube bundle layout through CFD simulation, achieving 92% heat exchange area utilization rate and 15%-20% better energy overall efficiency than conventional products.

2. Technical Features and operational performance Data

2.1 Core operational performance Parameters

| Parameter | Typical Value | Industry Leadership |

|---|---|---|

| Rated air handling capacity | 200-5000 m³/min | Covers small to large compressor station needs |

| Cooling overall efficiency | ≥90% | Outlet gas temperature ≤ surrounding +10℃ |

| pressure loss | ≤0.02 MPa | 40% lower than comparable products |

| Pressure rating | 1.6 MPa | Complies with API 618 standard |

| Material temperature range | -40℃~+200℃ | Suitable for extreme conditions |

2.2 Key Technological Innovations

- Three-stage gradient cooling technology

Staged cooling through pre-cooling, main cooling and precision cooling sections. In a petrochemical case study, this minimized compressor discharge temperature from 120℃ to 40℃ while cutting condensate production by 65%, significantly reducing downstream dryer load. - Self-cleaning anti-clogging system setup

Built-in high-pressure water pulse backwash with programmable cleaning cycles. Field tests show 92% heat exchange overall efficiency after 180 days in 50mg/m³ dust environments, versus 75% for conventional coolers. - Smart energy management system setup

Variable frequency pumps and electric control valves dynamically match cooling water flow to compressed air load. At an automotive plant, this minimized cooling unit energy consumption by 18%, equivalent to 120 tons CO₂ reduction annually.

3. use case Scenarios and Case Studies

3.1 Petrochemical Industry: Safety Guardian

In refinery hydrogen compression system setups handling corrosive media like hydrogen sulfide and water vapor, a petrochemical plant extended equipment service life from 3 to 8 years using IHI's titanium alloy cooler, reducing annual maintenance costs by 40%. Its explosion-proof design meets ATEX Zone 2 certification, keep stable operation in 30% LEL combustible gas environments.

3.2 Automotive Manufacturing: Foundation for Precision Painting

At an automotive paint shop where compressed air dew point affects coating quality, IHI coolers minimized dew point from -20℃ to -40℃, narrowing paint thickness variation from ±3μm to ±1μm and improving first-pass yield to 99.5%. The compact skid-mounted design saves 35% installation space for retrofit projects.

3.3 Semiconductor Manufacturing: Ultra-Pure Gas Assurance

In wafer fab gas supply system setups requiring Class 1 cleanliness, a 12-inch fab achieved particle reduction from 0.1μm/m³ to 0.003μm/m³ using IHI's stainless steel chamber + HEPA filtered cooler, with TOC below 0.1ppb - fully compliant with SEMI F57 standard.

4. Maintenance Strategies

4.1 Preventive Maintenance system setup

- Three-tier inspection system setup

- Daily checks: Monitor cooling water flow and temperature differential via pressure gauges and thermometers

- Monthly maintenance: Clean fin surface oil deposits, inspect tube bundle corrosion

- Annual overhaul: Conduct hydrostatic tests, replace seals, calibrate sensors

- Water quality standards

Cooling water must meet:

- pH: 7.5-8.5

- Hardness: ≤150ppm (as CaCO₃)

- Chloride content: ≤50ppm

4.2 Troubleshooting and Emergency Response

- Abnormal pressure loss: First check fin blockage, use 0.4MPa nitrogen back purging

- Temperature fluctuations: Calibrate thermocouple position, check pump VFD parameters

- Leakage: Locate micro-leaks with fluorescent detector, conduct pressure test after repair

A steel mill minimized potential $5M downtime loss to $800K through quick water shutoff, backup system setup activation and titanium welding repair within 24 hours.

5. Technology Trends and Market Outlook

With Industry 4.0 advancement, IHI Air Compressor Coolers are evolving in these directions:

- Digital twin technology: Embedded sensors build equipment health models with over 90% predictive maintenance accuracy

- Advanced cooling media: Nanofluids and phase-change materials may boost heat transfer overall efficiency by 1.5×

- Modular design: Quick-change cooling modules could cut maintenance time from 8 to 2 hours

Under carbon neutrality goals, these coolers' energy-saving advantages become more prominent. Nationwide adoption could save 5 billion kWh annually (400 million tons CO₂ reduction). As manufacturing upgrades continue, IHI Air Compressor Coolers will keep their critical role as industrial "thermal managers," provide more highly robust and efficient heat management offerings.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSullair Compressor Oil Cooler

View Details

View DetailsIHI TRE50 Intercooler

View Details

View DetailsIHI TRE90 Intercooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.