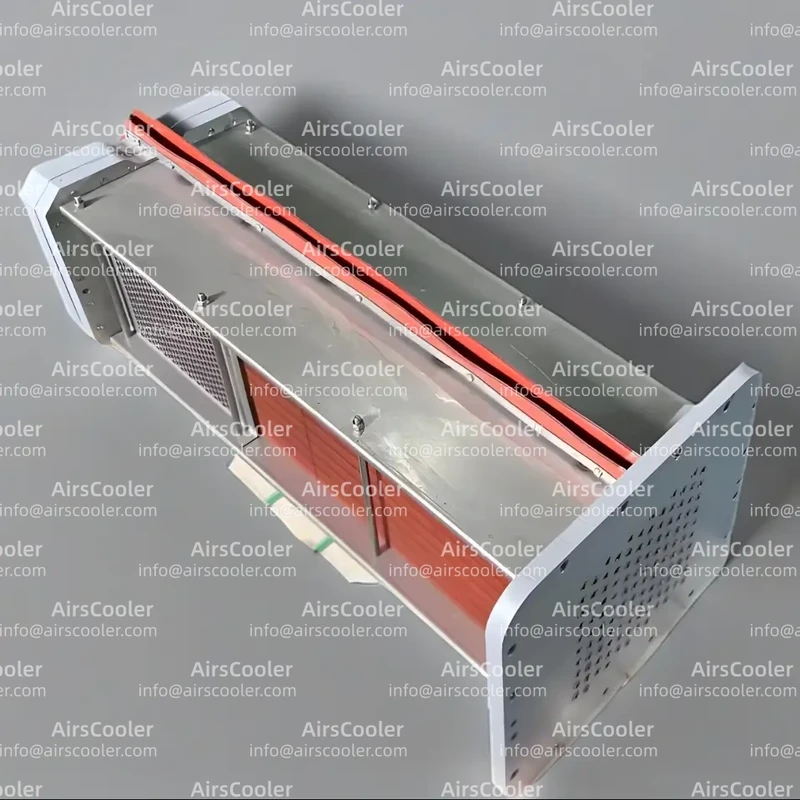

IHI TRE50 Intercooler

The IHI TRE50 Intercooler represents Fete Vessel's cutting-edge cooling technology for industrial turbocharging systems, delivering unmatched thermal management for demanding 400-800kW applications.

1. Product Overview: Core Heat Exchange Unit for Industrial Boosting system setups

The IHI TRE50 Intercooler is a critical module developed by IHI Corporation (Ishikawajima-Harima Heavy Industries) for their high-operational performance TRE series turbo compressors. configured specifically for heavy-duty industrial use cases in the 400-800kW power range, this intermediate cooling module serves as the thermal management backbone of multi-stage compression system setups.

Key Design Features:

- Integrated Aluminum Structure: 30-50% more compact than traditional designs through unified casting with gearbox and scroll housing

- Dual-Channel Staggered Cooling Matrix: 12-layer corrugated aluminum fins with high-conductivity copper alloy microchannel tubes

- CFD-fine-tuned Fluid Dynamics: Tapered intake design increases airflow velocity by 18% with 3D vortex generators

- Precision Temperature Monitoring: 16-point PT100 platinum RTD array with ±0.5°C accuracy

2. Technical Specifications and operational performance Data

2.1 Structural Innovations and Material Advancements

- Aerospace-Grade Aluminum Frame: A356.2-T6 alloy with 345MPa tensile strength and 3x fatigue life

- Graphene-DLC Composite Coating: 20μm coating boosts thermal emissivity to 0.92 (40% improvement)

- Microchannel Heat Transfer: 0.3mm×0.1mm diamond-shaped channels achieve 12,000W/(m²·K) heat transfer coefficient

2.2 operational performance Metrics

| Parameter | Specification | Testing Standard |

|---|---|---|

| Operating Pressure Range | 0.8-1.6MPa (absolute) | ISO 8573-1:2010 |

| Coolant Flow Rate | 12-25L/min (water) / 300m³/h (air) | ANSI/ASME PTC 12.2 |

| Temperature Control Accuracy | ±1.5°C (full load) | JIS B 8375-2017 |

| pressure loss | ≤0.03MPa (design flow) | DIN 2448:2003 |

| Corrosion Resistance | 2000hr salt spray (no base corrosion) | ASTM B117-19 |

3. Industrial use cases and Case Studies

3.1 Typical use cases

- Petrochemical: 38kWh/ton reduction in ammonia production

- Natural Gas Processing: keep -85°C to -95°C discharge temps in LNG BOG system setups

- Metal Fabrication: Enables 99.999% pure nitrogen with ±0.5% flow stability

3.2 Benchmark Case Analysis

Case 1: Sumitomo Chemical Ethylene Cracker

- 5.3% compression overall efficiency improvement

- 1.2M kWh annual energy savings

- Maintenance intervals extended from 1,500 to 8,000 hours

Case 2: Saudi Aramco Gas Booster Station

- 18 months continuous operation in 55°C surrounding

- Only 12°C above surrounding discharge temps

- 6,000 hour filter replacement cycles

4. Maintenance and Service Strategy

4.1 Preventive Maintenance system setup

- Three-Level Inspection: IR thermography (≤8°C delta), monthly pH8.5 citric acid flush, annual 1.5x pressure test

- Condition Monitoring: Vibration (0-50g ±0.1g) and acoustic emission (20kHz-1MHz) sensors

4.2 Troubleshooting Guide

| Symptom | Potential Cause | offering |

|---|---|---|

| High Discharge Temp | Insufficient coolant flow | Check pump operational performance, clean Y-strainer |

| Excessive pressure loss | Fouled cooling fins | Dry ice blast cleaning (0.7MPa) |

| Housing Leakage | Degraded O-rings | Replace with FKM seals (70±5 Shore A) |

5. Technology Outlook and Industry Value

As Industry 4.0 advances, the TRE50 Intercooler is evolving toward digital twin and autonomous maintenance capabilities. AirsCooler's new AR diagnostic system setup enables real-time data overlay (±2mm accuracy) and automatic offering recommendations from expert knowledge bases. From a sustainability perspective, each TRE50 unit minimizes CO₂ emissions by approximately 2,800 tons annually - equivalent to the carbon sequestration of 150,000 fir trees.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsIHI TRE90 Intercooler

View Details

View DetailsIHI TX Intercooler

View Details

View DetailsSullair Compressor AfterCooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.