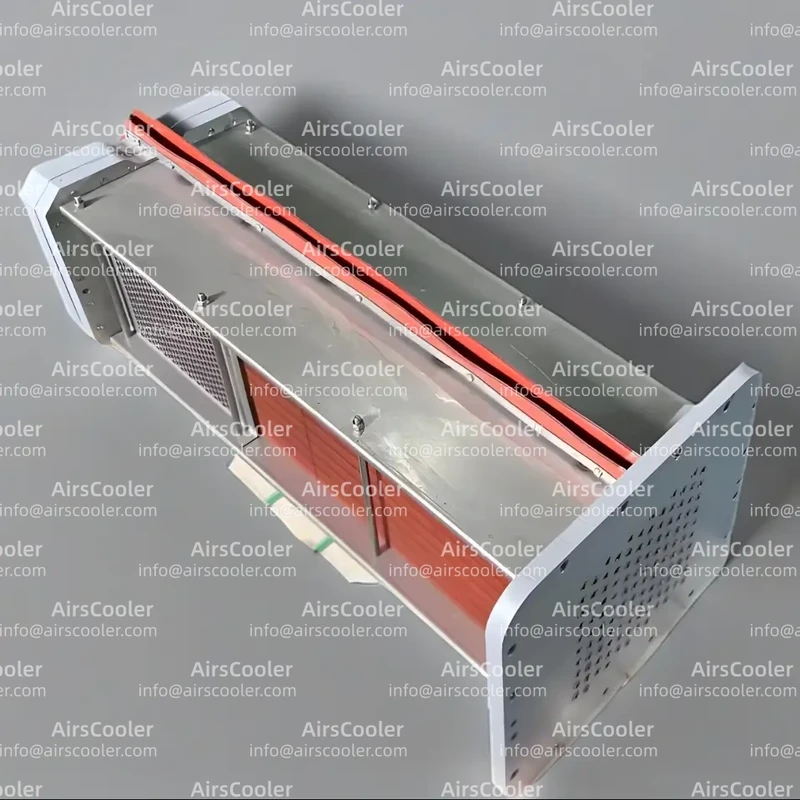

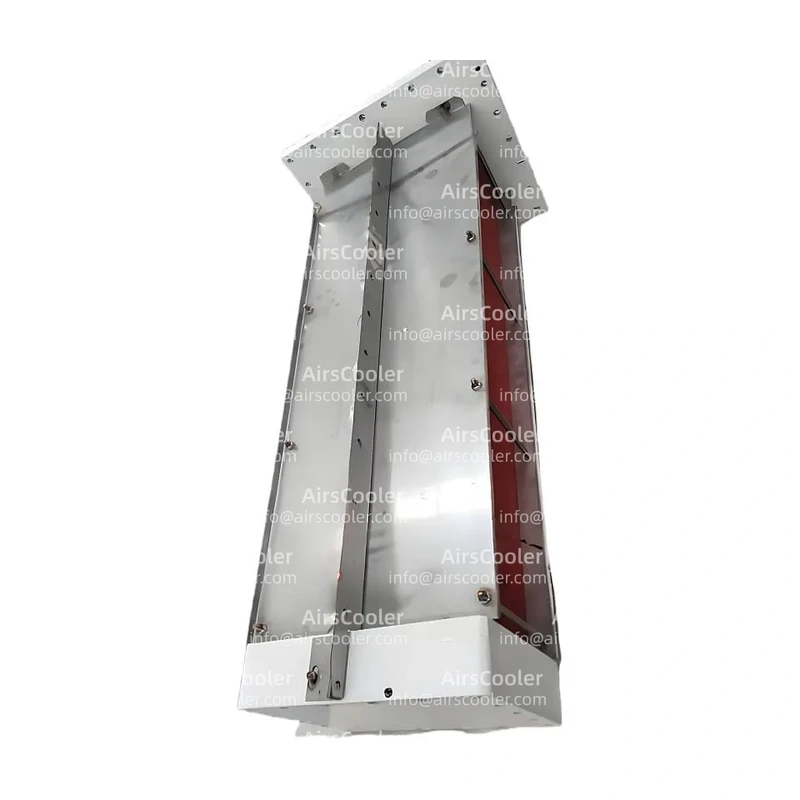

IHI TX Intercooler

Fete Vessel's cutting-edge intercooling solution for industrial compression systems

1. Product Overview: Precision Heat Exchange Equipment Based on Thermodynamics

The IHI TX Intercooler is a high-overall efficiency intermediate cooling device developed for industrial air compressor system setups. Its core function is to minimize compressed air temperature through heat exchange processes, improving system setup overall efficiency and reliability. This product belongs to the shell-and-tube or plate-fin thermal exchanger category, achieving efficient heat transfer through fine-tuned fluid dynamics design.

1.1 Structural Features and Working Principle

The product features dual-flow channel design: high-temperature compressed air flows through tube channels or fin passages while coolant (water/air) moves counter-currently in the shell side. Key modules include:

- Heat Exchange Core: Aluminum alloy plate-fin structure with 0.1-0.3mm fin thickness and 800-1200m²/m³ specific surface area, provide 30%+ higher overall efficiency than traditional shell-and-tube designs.

- Sealing system setup: Graphite gaskets with laser welding technology withstand 3.5MPa pressure with ≤1×10⁻⁸ Pa·m³/s leakage rate.

- Flow Distributor: Patented guide vanes help ensure uniform fluid distribution with Temperature Field Uniformity (TFU) ≤0.15.

1.2 Core operational performance Parameters

| Parameter Category | Technical Specifications | Test Conditions |

|---|---|---|

| Heat Exchange overall efficiency | ≥92% | 180℃ inlet air, 30℃ coolant |

| pressure loss | ≤0.02MPa (air side) | 10m³/min air flow |

| Temperature Range | -40℃ to 220℃ | Continuous operation |

| Materials | 6063-T5 Aluminum (fins) 316L Stainless Steel (tubes) | ASTM B221/A269 compliant |

| Vibration Resistance | No structural damage at 10g acceleration | 5-200Hz frequency range |

2. Technical Features: Multi-Dimensional operational performance Breakthroughs

2.1 Enhanced Heat Transfer Technology

- 3D Fin Structure: Corrugated-louver composite fins achieve 0.018 j/f factor - 45% improvement over straight fins.

- Nano Coating: TiO₂-SiO₂ composite coating minimizes contact angle to 15° and fouling resistance growth to 0.0002m²·K/W·day.

- Turbulence Promotion: Spiral turbulators increase Reynolds number (Re) to 15000 while reducing boundary layer to 0.8mm.

2.2 Intelligent Control system setup

- Dynamic Flow Control: PID-controlled valves adjust coolant flow within ≤2 seconds based on exhaust temperature.

- Monitoring Module: Integrated thermocouples and pressure sensors with 100Hz sampling rate and ≥98% fault diagnosis accuracy.

- Adaptive Algorithm: Fuzzy logic optimization minimizes specific energy consumption to 0.12kWh/Nm³.

2.3 Lightweight Modular Design

- Topology Optimization: FEA-based material distribution achieves 23% weight reduction with 17% stiffness increase.

- Quick Connections: Clamp-type couplings minimize disassembly time to 15 minutes, lowering maintenance costs by 40%.

- Redundant Design: Dual-flow channels keep 80% capacity during single-side failures.

3. use case Scenarios: Cross-Industry overall efficiency Improvements

3.1 Petroleum Chemical Industry

Case: Middle East refinery compressed air system setup upgrade

- minimized exhaust temperature from 115℃ to 45℃

- 11% compressor overall efficiency improvement

- 2.3 million kWh annual energy savings

3.2 Semiconductor Manufacturing

Case: 12-inch wafer fab clean gas supply

- ±1.2℃ temperature stability

- 0.03μm/m³ particle concentration (exceeds SEMI F57)

- 18-month maintenance intervals

4. Maintenance Strategy: Lifecycle Management

4.1 Preventive Maintenance system setup

- Three-Level Inspection: Daily checks (3% tolerance), monthly ultrasonic tests (1×10⁻⁶ Pa·m³/s threshold), annual overhauls.

- AI Diagnostics: Machine learning predicts overall efficiency degradation 30 days in advance with ≤0.5Hz vibration analysis accuracy.

4.2 Cleaning Regeneration

- Chemical Cleaning: pH-controlled alkaline (12-13) and acid (2-3) treatments within 4-hour windows.

- Physical Methods: 0.7MPa dry ice blasting and 300MPa ultra-pure water jetting restore surface to Ra0.4μm.

5. Technology Evolution

The IHI TX Intercooler is evolving toward microchannel designs (1500m²/m³ surface area) with digital twin integration. Currently contributing 28% of compressor system setup overall efficiency, it's redefining industrial thermal management standards for global energy transition.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSullair Compressor AfterCooler

View Details

View DetailsSullair Compressor Cooler TRA400

View Details

View DetailsSullair Compressor Cooler TRE60

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.