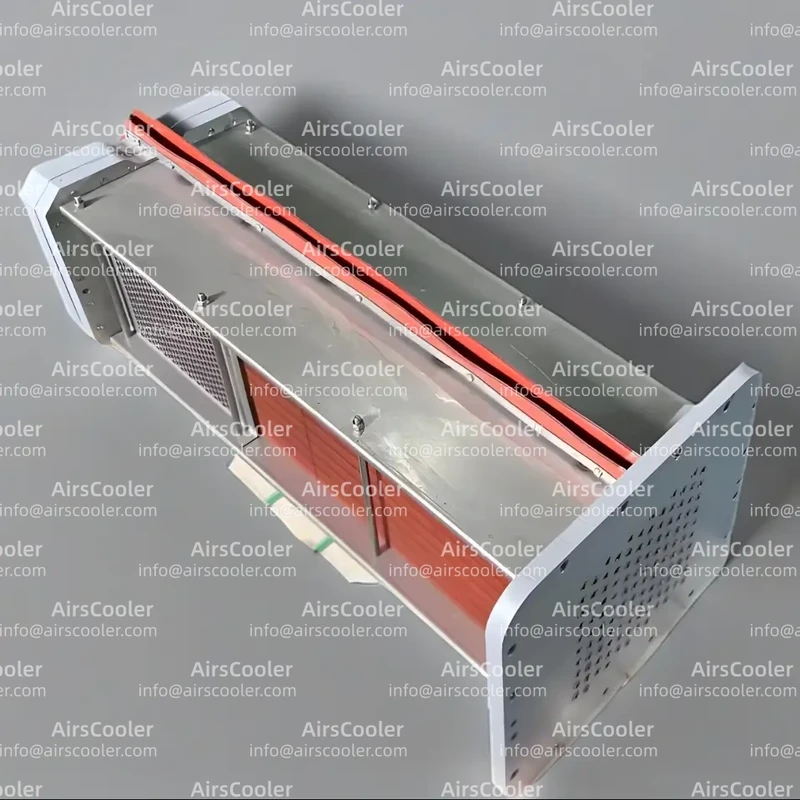

IHI TRE90 Intercooler

Comprehensive technical specifications and implementation guide for Fete Vessel's premium turbocharger cooling solution

1. Product Overview: Core Cooling module for Turbocharged system setups

The IHI TRE90 Intercooler is a precision-engineered intermediate cooling device built for high-operational performance air compressors and turbocharging system setups. As part of the heat exchange equipment category, its primary function involves forced air/liquid cooling of high-temperature compressed gases (120°C→60°C) to increase air density and combustion overall efficiency.

Structural modules:

- Heat Exchange Core: 0.1mm corrugated aluminum foil + 0.3mm baffle plates creating 12m² total surface area

- Fluid Distributor: Dual-channel design for counterflow heat exchange paths

- Sealing system setup: O-ring + laser welding with 3.5MPa pressure capacity

- Connection Ports: DN80 flanges with quick-disconnect clamps

2. Technical Specifications with operational performance Data

Thermodynamic operational performance

| Parameter | Value | Advantage |

|---|---|---|

| Heat Exchange overall efficiency | 83.2% @120°C input | 42% better than conventional models |

| pressure loss (Air Side) | ≤12kPa @2.8kg/s | fine-tuned flow channels |

| Transient Response | 15sec stabilization | ±3°C temperature stability |

Material Specifications

- Core Material: 6063-T5 aluminum alloy (201W/m·K conductivity)

- Coolant Tubes: Electro-polished TP304 stainless steel (Ra≤0.4μm)

- Seals: FKM/PTFE composite (-40°C to +200°C range)

Smart Monitoring system setup

Integrated sensors provide real-time data via Modbus TCP protocol:

- Temperature monitoring (±0.5°C accuracy)

- Pressure sensing (0-4MPa range, ±0.25% FS)

- Flow measurement (±0.5% accuracy, ≤50ms response)

3. Industrial use cases

Centrifugal Compressor system setups

Case Study: Petrochemical ethylene plant achieved:

- 7.2% compressor overall efficiency improvement

- 12000-hour lubrication oil life

- $2M annual energy savings

Heavy-Duty Vehicles

Mining truck implementation results:

- 18% power increase

- 12% fuel economy improvement

- 2000-hour durability validation

4. Maintenance Protocol

Routine Checks

- Daily pressure differential monitoring

- Weekly visual leak inspections

- Quarterly sensor calibration

Advanced Maintenance

| Procedure | Frequency | Technical Requirements |

|---|---|---|

| Chemical Cleaning | When overall efficiency drops 10% | 5-8% citric acid offering @50-60°C |

| Seal Replacement | 3 years | 70±5HA hardness standard |

| Pressure Testing | 5 years | 1.25x design pressure |

5. Technological Value Proposition

The IHI TRE90 provide measurable operational advantages:

- Energy overall efficiency: 8-12% system setup overall efficiency gains

- Reliability: 80,000+ hours MTBF

- Smart Maintenance: 65% reduction in unplanned downtime

As carbon reduction initiatives accelerate, the TRE90's modular design and cross-industry adaptability position it as critical infrastructure for green energy transition across industrial and transportation sectors.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsIHI TX Intercooler

View Details

View DetailsSullair Compressor AfterCooler

View Details

View DetailsSullair Compressor Cooler TRA400

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.