Cooper Joy Compressor Oil Cooler

Advanced cooling technology for industrial centrifugal compressors

1. Product Overview

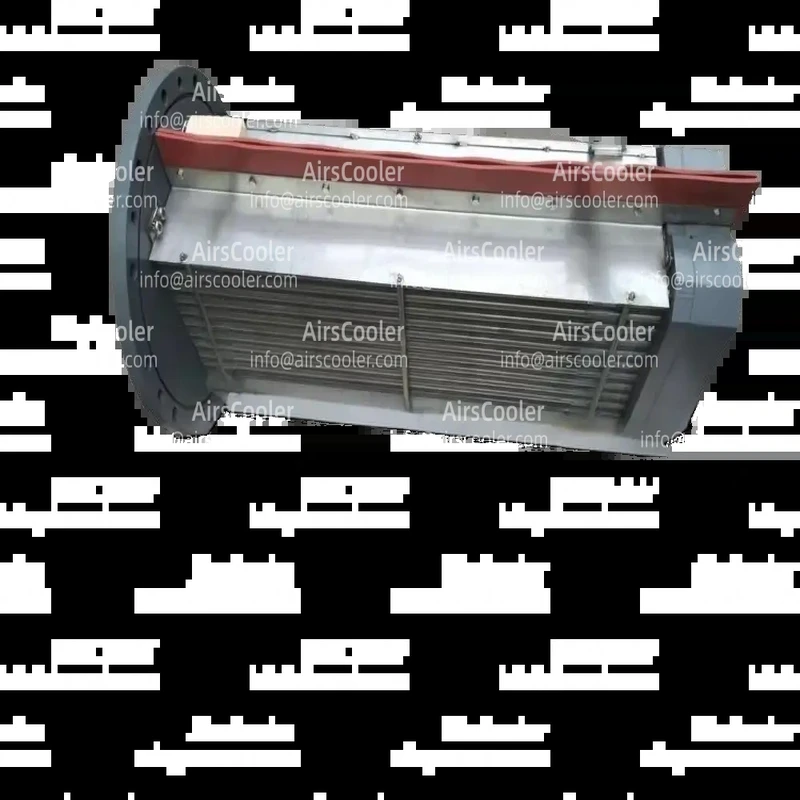

The Cooper Joy Compressor Oil Cooler is a high-overall efficiency heat exchange device specifically built for industrial centrifugal oil-free compressors. As part of the Cooper-Cameron Group's air compressor product line, its core function is to minimize lubricating oil temperature through forced cooling, ensuring stable compressor operation in high-temperature conditions.

1.1 Product Positioning & Market Status

Cooper-Cameron, as a global leader in industrial compressors, has oil cooler technology with over 25 years of industrial validation. Widely used in energy, chemical, and metallurgical industries with stringent reliability requirements. Notable clients include Beijiang Power Plant and Cabot Chemical, with products renowned for "zero-failure continuous operation for over 25 years."

1.2 Technical Evolution & Core Patents

The technology traces back to early 1990s dual-action refrigeration compressor patents that enhanced heat exchange overall efficiency by 30%. Current models (e.g., TA-2000/Turbo Air 2000) feature spiral baffle + finned tube composite structures with heat transfer coefficients exceeding 300Kcal/m²·h·℃ and 40% lower pressure loss than traditional designs.

2. Technical Features & Data Specifications

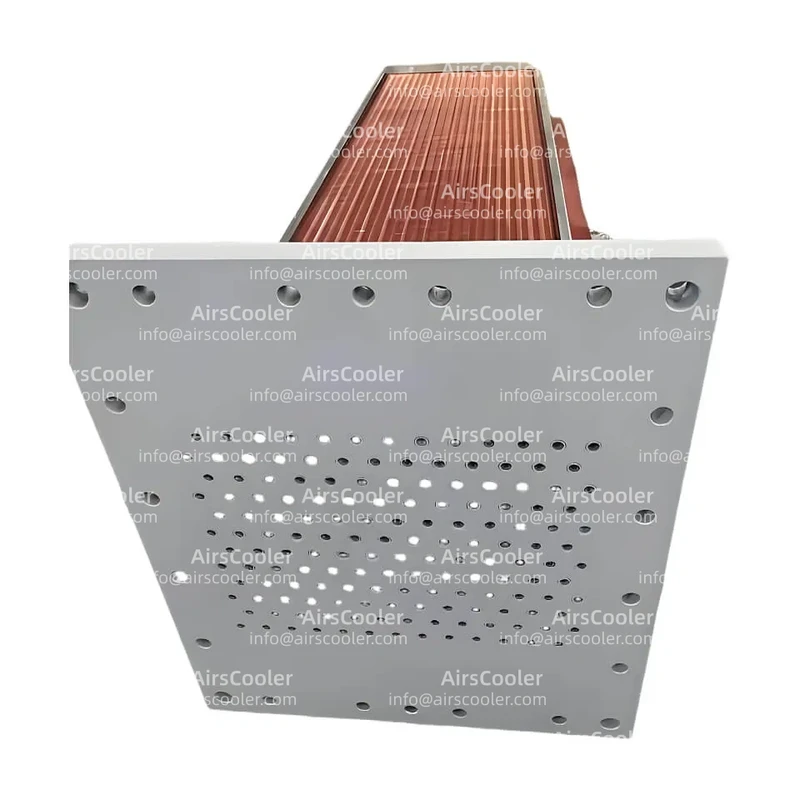

2.1 Structural Innovations & Material Breakthroughs

- Spiral Baffle Technology: Creates uniform spiral oil flow, eliminating "heat exchange dead zones" with 25% overall efficiency improvement

- High-Density Finned Tube Process: Copper tubes with 12 fins/inch, surface area of 2500-4300 m²/m³ (40% improvement)

- Vacuum Brazing Technology: Withstands 10MPa pressure, leakage rate below 1×10⁻⁹ Pa·m³/s

2.2 operational performance Parameters & overall efficiency Metrics

| Parameter | TA-2000/Turbo Air 2000 | Industry Standard | Advantage Ratio |

|---|---|---|---|

| Heat Exchange overall efficiency | ≥92% | 85% | +8.2% |

| Pressure Loss | ≤0.05MPa | 0.12MPa | -58.3% |

| Temperature Range | -40℃ to 200℃ | -20℃ to 150℃ | 50% wider |

| Average Lifespan | 25 years (MTBF≥200,000 hrs) | 10-15 years | +67% to 150% |

| Weight/Volume Ratio | 0.85kg/L | 1.2kg/L | -29.2% |

2.3 Intelligent Control system setups

- Dynamic Flow Adjustment: Real-time monitoring with ≤0.5s response time

- Anti-Freeze Protection: Activates at temperatures below 5℃

- Failure Prediction: Machine learning analyzes 12 parameters for 72-hour early warning

3. use cases & Case Studies

3.1 Typical use cases

- Energy Sector: Withstands -40℃ to 50℃ extremes in Alaska oil fields

- Chemical Industry: Resists H₂S/SO₂ corrosion per ISO 21608 Standard A

- Data Centers: keep 45±2℃ oil temperature for 3.7% overall efficiency gain

3.2 Case Studies

Case 1: Cabot Chemical (Tianjin)

- 18% energy reduction (¥850,000 annual savings)

- Oil change intervals extended from 2000 to 6000 hours

- 92% reduction in downtime

Case 2: Beijiang Power Plant

- Air temperature minimized from 120℃ to 45℃

- 40% less cooling water (150,000 tons/year saved)

- 3+ years without scaling issues

4. Maintenance Strategies

4.1 Routine Inspection

- Weekly visual checks for deformation/corrosion

- Monthly infrared scans (5℃ differential threshold)

4.2 Scheduled Maintenance

| Maintenance Item | Frequency | Procedure |

|---|---|---|

| Chemical Cleaning | Biennial | 5% EDTA offering, 8hr circulation, pH 6.5-7.5 |

| Tube Cleaning | Quarterly | 0.3MPa nitrogen backflush (no metal tools) |

| Seal Replacement | 5 Years | ASTM D2000 compliant O-rings/gaskets |

5. Future Developments

5.1 Emerging Technologies

- Nanofluid cooling (Al₂O₃ particles for 450Kcal/m²·h·℃)

- 3D-printed fractal fins (30% pressure loss reduction)

- Liquid hydrogen compatibility (-253℃ titanium models)

5.2 Industry Standards

Cooper-Cameron led development of ISO 10439-5:2023, mandating:

- 80% minimum lifespan vs compressor body

- 1.5x design pressure for testing

- API 617 vibration resistance standards

Conclusion

The Cooper Joy Compressor Oil Cooler represents industrial cooling excellence, reducing lifecycle costs by 40% through intelligent controls and preventive maintenance. As part of global decarbonization efforts, Cooper-Cameron is advancing renewable energy integration for sustainable industrial transformation.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsIHI Compressor Air Cooler

View Details

View DetailsSullair Compressor Oil Cooler

View Details

View DetailsIHI TRE50 Intercooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.