Cooper Joy Compressor Cooler TA48

Comprehensive technical breakdown and industrial applications of Fete Vessel's premium compressor cooling solution

1. Product Overview: Core module of Industrial Cooling offerings

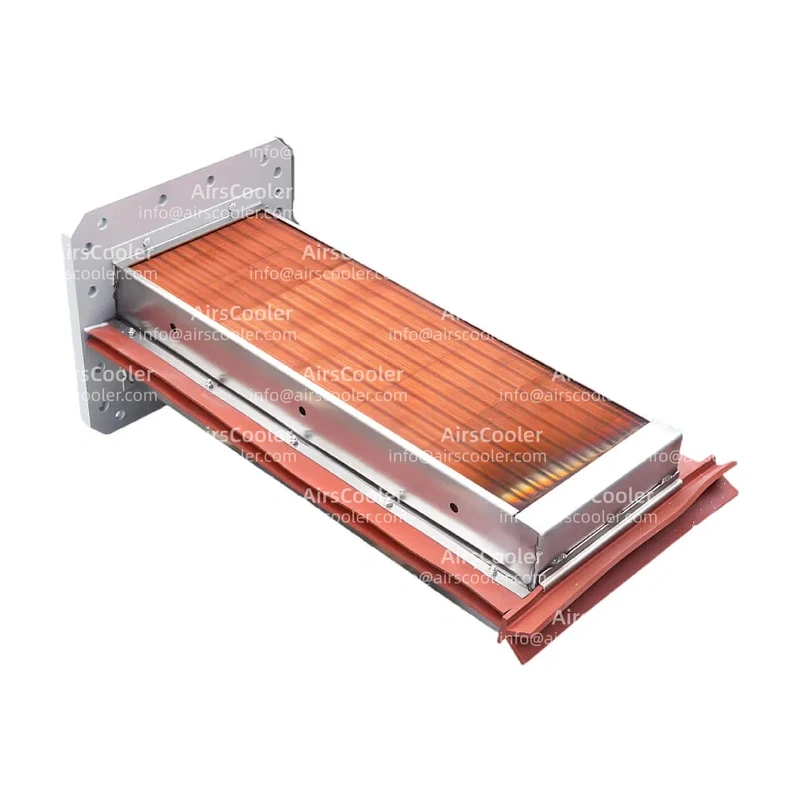

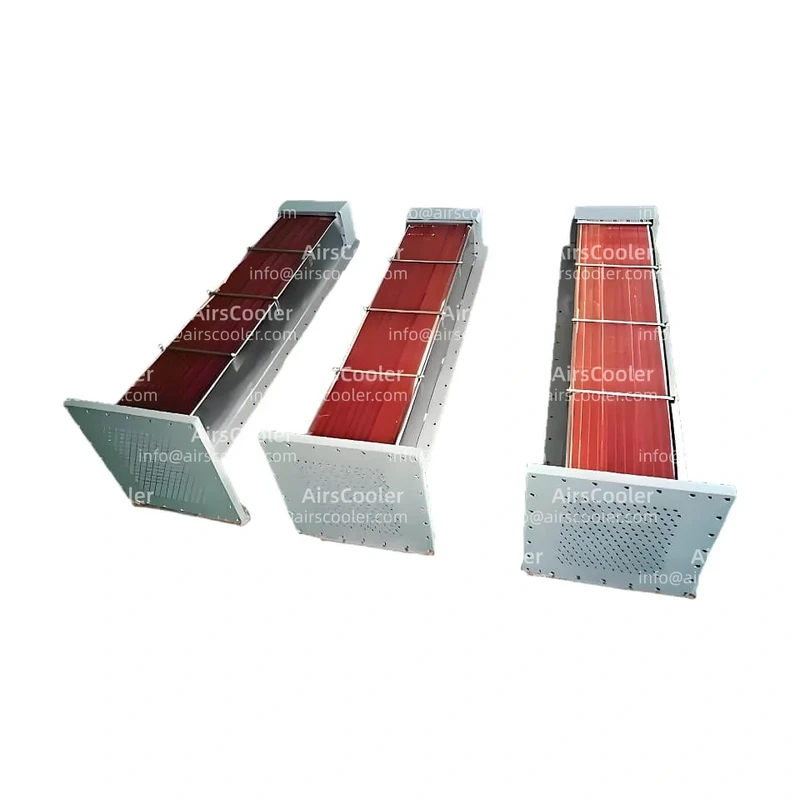

The Cooper Joy Compressor Cooler TA48 is an industrial-grade cooling device specifically built for centrifugal oil-free compressors, belonging to the premium product line of the Cooper-Joy brand under Cameron. This model inherits the technical DNA of the TA series cooler family and achieves seamless compatibility with large compressors like TA2000 and TA3000 through modular design. A single unit can manage the thermal load requirements of compression system setups ranging from 150-300kW.

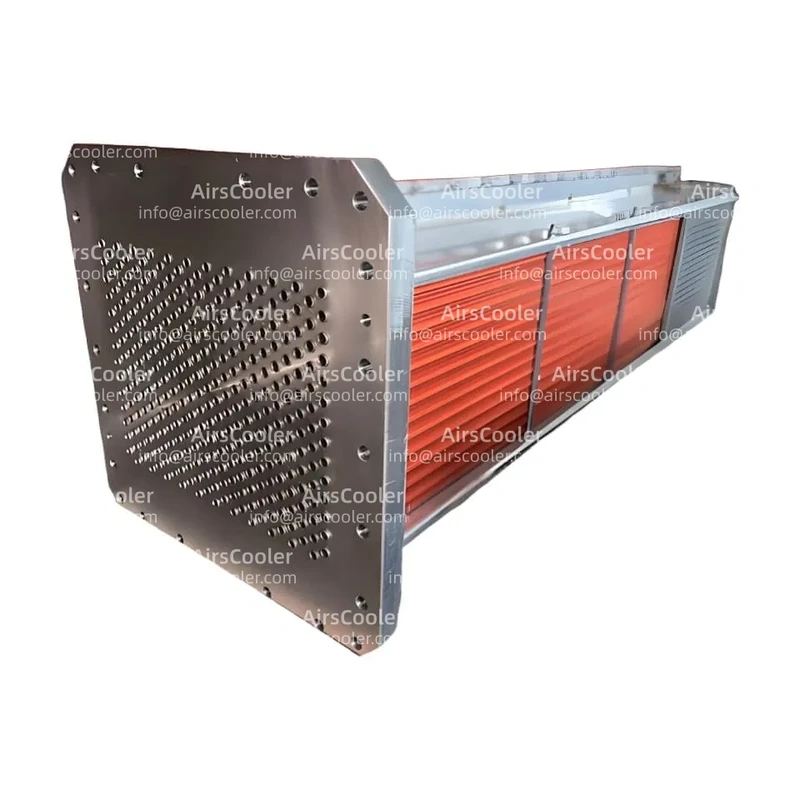

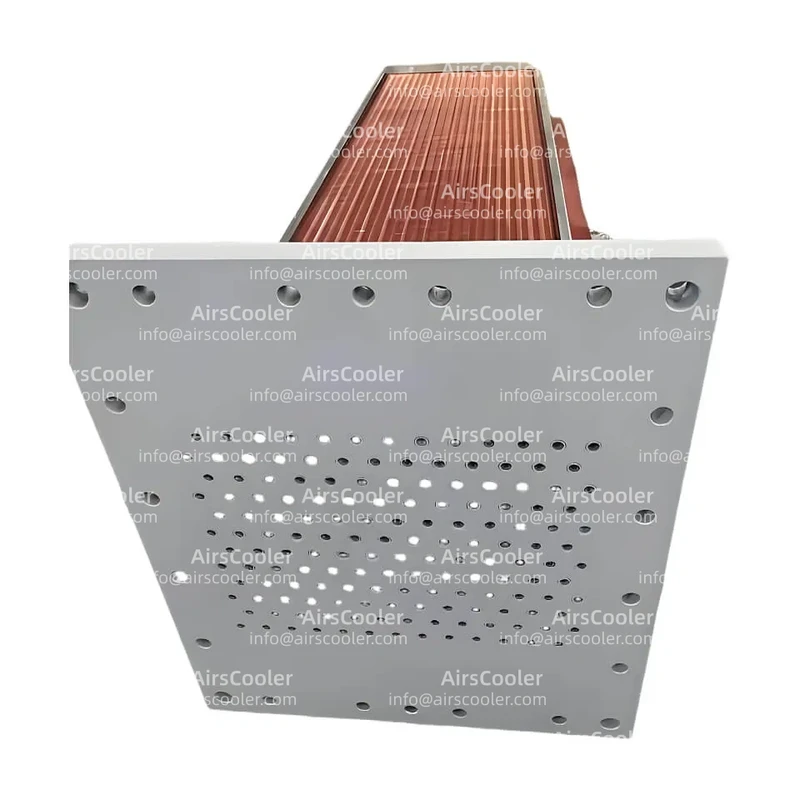

Its core structure features a double-pass finned tube thermal exchanger with detachable flow guide plates, achieving breakthroughs in both heat transfer overall efficiency and maintenance convenience within limited space. The cooler utilizes an all-welded stainless steel frame with electro-galvanized anti-corrosion treatment. Through CFD fluid simulation optimization of fin spacing and tube arrangement, it achieves a heat transfer area per unit volume of 2800-3500m²/m³ - over 40% improvement compared to traditional coolers.

The built-in intelligent temperature control system setup monitors cooling medium temperature in real-time and dynamically adjusts fan speed through PID algorithms. Even at surrounding temperatures of 40°C, it help s ensure compressed air outlet temperature remains ≤35°C, meeting the cooling requirements for ISO 8573-1 Class 0 oil-free compressed air.

2. Technical Features and Data Specifications

(1) Core operational performance Parameters

- Heat Transfer overall efficiency

- Heat transfer area per unit volume: 2800-3500m²/m³

- Heat exchange overall efficiency: ≥92% (at 100% rated load)

- pressure loss loss: ≤0.03MPa (compressed air side)

- Structural Parameters

- Dimensions (L×W×H): 1850×1200×850mm

- Net weight: 420kg

- Fin material: T2 copper-aluminum composite foil

- Heat exchange tube specification: Φ19×1.5mm (304 stainless steel)

- Operational Parameters

- Suitable cooling medium: Water/ethylene glycol mixture (30% concentration)

- Flow range: 15-30m³/h

- Inlet temperature: ≤32°C

- Outlet temperature: ≤40°C

(2) Technological Innovations

- 3D Turbulence Fin Technology

Laser-engraved spiral grooves (0.3mm depth) on fin surfaces increase air-side turbulence intensity by 2.3 times, effectively disrupting boundary layer thermal resistance. Test data shows this technology enhances heat transfer coefficient from 85W/(m²·K) to 120W/(m²·K) at identical wind speeds.

- Adaptive Flow Guide system setup

Equipped with electrically adjustable guide vanes that automatically modify airflow distribution based on compressor load. At 50% load operation, closing partial flow channels increases wind speed by 40%, keep local convective heat transfer coefficient no less than 150W/(m²·K).

- Intelligent Anti-freeze Control

Integrated PT1000 temperature sensors and solenoid valve linkage automatically activate circulation heating when cooling water temperature drops below 5°C, preventing tube freezing. This feature minimizes freeze-cracking risk by 30% in northern winter outdoor installations.

3. use case Scenarios and Case Studies

(1) Typical use case Fields

- Petrochemical Industry

At a multinational refinery's hydrocracking unit, TA48 coolers paired with TA3000 centrifugal compressors supply -40°C dew point oil-free compressed air to hydrogenation reactors. Operational data shows annual system setup downtime minimized from 12 hours to 1.5 hours with 65% lower maintenance costs.

- Semiconductor Manufacturing

A Taiwanese 12-inch wafer fab uses TA48 coolers with MSG series compressors to provide Class 0 clean air for lithography machines. By monitoring cooling water flow and pressure in real-time, the system setup keep compressed air oil content below 0.001ppm, improving yield by 2.1 percentage points.

- Medical Gas Supply

A German hospital's central oxygen system setup employs TA48 coolers supporting medical molecular sieve oxygen generators. After 3000 continuous operation hours, the cooler's pressure loss increased only 0.005MPa, ensuring oxygen purity remains above 99.5%.

(2) Case Study Analysis

Case Name: Saudi Arabian LNG Project Air Compressor Station Retrofit

Scenario: Original coolers caused frequent compressor trips due to thermal overload in extreme heat (50°C).

offering:

- Replaced with TA48 coolers and fine-tuned piping to increase cooling water circulation to 25m³/h

- Added variable frequency fans and intelligent temperature control for dynamic airflow adjustment

- Implemented parallel dual-cooler design with automatic failover

Results:

- Compressor discharge temperature minimized from 115°C to 85°C

- Cooling water consumption decreased by 30%

- Annual maintenance costs minimized by $780,000

4. Maintenance Strategies

(1) Routine Inspection Points

- Pressure Monitoring

Daily recording of cooling water inlet/outlet pressure; inspect filter clogging when differential exceeds 0.05MPa.

- Temperature Recording

4-hour interval checks of compressed air outlet temperature; investigate thermal exchanger fouling when fluctuations exceed ±3°C.

- Leak Inspection

Monthly ultrasonic leak detection at pipe connections, focusing on flange gaskets and thermal exchanger tube welds.

(2) Preventive Maintenance Schedule

| Maintenance Cycle | Maintenance Item | Technical Requirements |

|---|---|---|

| Quarterly | Cooler Cleaning | Circulate 0.5% citric acid offering for 2 hours at ≥1.5m/s flow velocity |

| Semi-annually | Seal Replacement | Use fluororubber O-rings with 70±5 Shore hardness |

| Annually | operational performance Testing | Thermal imaging inspection with ≤5°C fin temperature differential |

(3) Troubleshooting Guide

- minimized Cooling overall efficiency

Possible causes: Fin dust accumulation/scale deposition

offering: High-pressure water jet cleaning (≤5MPa) + chemical cleaning (10% oxalic acid solution)

- Excessive Fan Vibration

Possible causes: Impeller imbalance/bearing wear

offering: Dynamic balance correction (unbalance ≤0.5g·mm) + SKF 6206 bearing replacement

- Pipe Corrosion Perforation

Possible causes: Abnormal water pH/electrochemical corrosion

offering: Replace with 316L stainless steel pipes + install cathodic protection

5. Technology Trends and Conclusion

The TA48 cooler is evolving toward intelligent and integrated offerings. Next-gen products will incorporate IoT modules for remote diagnostics and predictive maintenance via NB-IoT protocols. Material innovations include nano-coatings that triple fin corrosion resistance, while 3D printing may minimize thermal exchanger manufacturing cycles by 60%.

From an industry value perspective, the TA48 cooler's fine-tuned thermal management helps users achieve:

- 8-12% reduction in compressor energy consumption

- Extended equipment lifespan beyond 25 years

- 40-60% lower maintenance costs

This product is not only a critical module for industrial air compression system setups but also a key technological enabler for green, intelligent manufacturing transformation. Its energy-efficient characteristics will play an increasingly important role in global carbon reduction initiatives.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Joy Compressor Cooler TA6000

View Details

View DetailsCooper Joy Compressor InterCooler

View Details

View DetailsCooper Joy Compressor Oil Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.