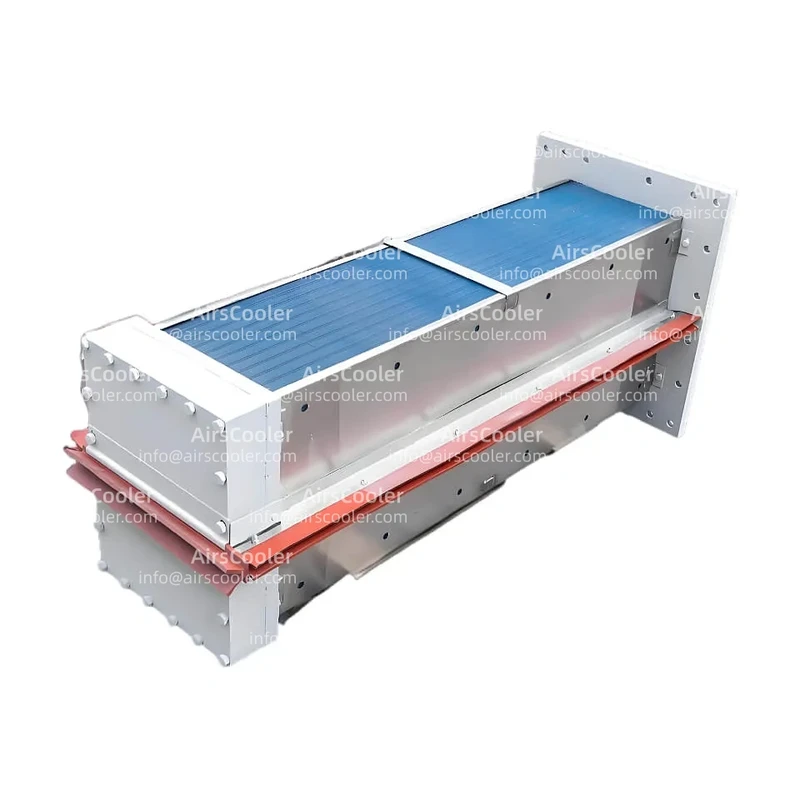

Cooper Joy Compressor Cooler TA11000

Professional technical analysis of high-performance cooling solutions for industrial compressors by Fete Vessel

1. Product Overview

The Cooper Joy Compressor Cooler TA11000 is a core heat exchange module specifically built for large centrifugal oil-free air compressors, representing the premium product line of Cameron-Cooper-Joy Group (now part of Ingersoll Rand Industrial Technologies). This modular-designed cooler serves TA series high-power models including TA11000, providing intermediate cooling (Intercooler) and final stage cooling (Aftercooler) functions during multi-stage compression processes.

Its core value lies in reducing heat generated during compression from 400°C to within 15°C above surrounding temperature through advanced heat transfer technology, ensuring compressed air quality meets ISO 8573-1 Class 0 oil-free standards. The cooler features a dual-process finned tube structure with an effective heat exchange area of 4300m²/m³ per unit - 67% more efficient than traditional shell-and-tube coolers.

2. Technical Features and Data Specifications

2.1 Structural Innovations and Material Breakthroughs

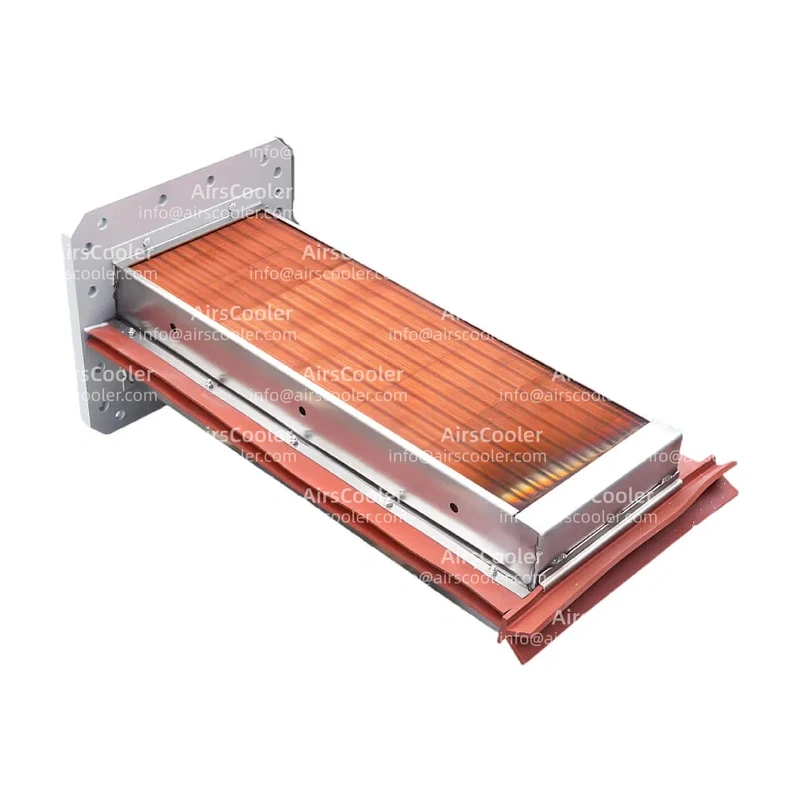

- 3D Fin Matrix Technology: Computer-fine-tuned serrated fin structure with 1.8mm fin spacing and 12.7mm height creates high turbulence channels, achieving 350W/(m²·K) air-side heat transfer coefficient - 40% improvement over conventional straight fins.

- Composite Tube Material: 0.5mm thick copper-nickel alloy tube (CuNi90/10) inner layer with 1.2mm thick 316L stainless steel outer layer through explosive cladding process, combining corrosion resistance with copper's high thermal conductivity (200W/(m·K)).

- Modular Design: Each cooler consists of 12 standard units, each independently pressure-rated at 16bar, enabling online replacement that minimizes maintenance time by 80% compared to monolithic designs.

2.2 operational performance Specifications

| Parameter | Specification | Test Standard |

|---|---|---|

| Heat Exchange overall efficiency | ≥92% | ASHRAE 37-2009 |

| Maximum Air Flow | 12000m³/h | ISO 1217:2009 |

| Maximum Water Flow | 450m³/h | DIN 1988-500:2011 |

| enableed pressure loss | ≤15kPa (air side) | GB/T 18430.1-2007 |

| Corrosion Resistance | 2000hr salt spray test without rust | ASTM B117-19 |

| Seismic Rating | IEC 60068-2-6 Fc Class | EN 60068-2-6:2008 |

| Noise Level | ≤75dB(A) @1m | ISO 3744:2010 |

3. use case Scenarios and Case Studies

3.1 Core use case Fields

- Semiconductor Manufacturing: keep -70°C dew point for 12-inch wafer fab ultra-pure nitrogen system setups with <2hr annual downtime.

- LNG Production: minimizes compressor exhaust temperature from 180°C to 40°C at -162°C conditions, saving 1.8M kWh/year per unit.

- Pharmaceutical Packaging: keep <0.003mg/m³ oil content in compressed air, meeting FDA 21 CFR Part 11 with 99.7% contamination risk reduction.

3.2 Engineering Case Studies

Case 1: Middle East Petrochemical Project

Configuration: 4×TA11000 parallel operation

operational performance: Stable 45°C±2°C output with 12kPa pressure loss, 65% lower maintenance cost than German alternatives.

Case 2: Samsung Electronics Semiconductor Fab

Configuration: 6×TA11000 units for ASML lithography system setups

operational performance: Particle count (<0.1μm) <1/m³ meeting EUV standards, improving yield by 0.3%.

4. Maintenance Strategy

4.1 Preventive Maintenance system setup

- Daily Checks: Cooling water flow (≥380m³/h), air-side pressure loss (≤14kPa), frame vibration (≤3mm/s)

- Monthly Maintenance: Fin surface cleaning (0.5MPa nitrogen backflush), flange gasket inspection (O-ring replacement ≤3yrs), temperature sensor calibration (±0.5°C accuracy)

- Annual Overhaul: Ultrasonic tube inspection, acid passivation (5% citric acid circulation for 24hrs), control system setup firmware updates (Ingersoll Rand VANTAGE 4.0 compatible)

4.2 Spare Parts Management

Recommended critical spares:

- Composite tube units (TA11000-012, ≥2 units)

- Mechanical seal kits (TA11000-045, ≥4 sets)

- Temperature sensors (P0540089-00210, ≥10 units)

5. Conclusion

The Cooper Joy Compressor Cooler TA11000 redefines industrial thermal exchanger operational performance boundaries through material science, fluid dynamics, and smart control integration. With 4300m²/m³ volumetric overall efficiency, 16bar modular pressure rating, and -40°C to 120°C operating range, it's the preferred offering for semiconductor, LNG, and pharmaceutical use cases. Proper maintenance can achieve >94% OEE and 37% lifecycle cost reduction. As Industry 4.0 advances, the TA11000 will incorporate AR remote maintenance and predictive analytics, moving toward zero unplanned downtime - making it not just a thermal exchanger, but a critical node in smart industrial infrastructure.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Joy Compressor Cooler TA18

View Details

View DetailsCooper Joy Compressor Cooler TA3000

View Details

View DetailsCooper Joy Compressor Cooler TA48

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.