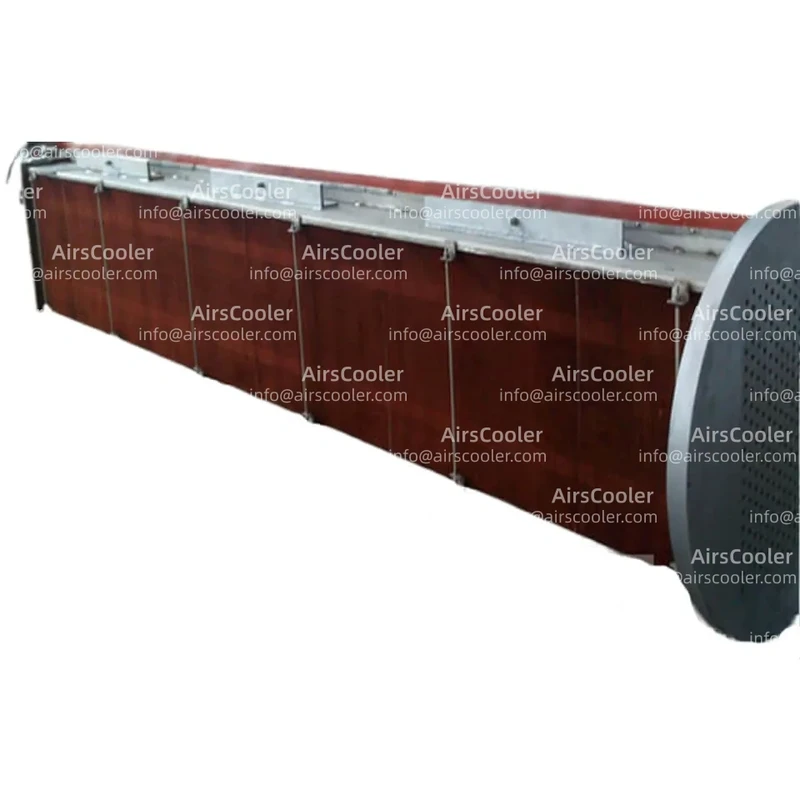

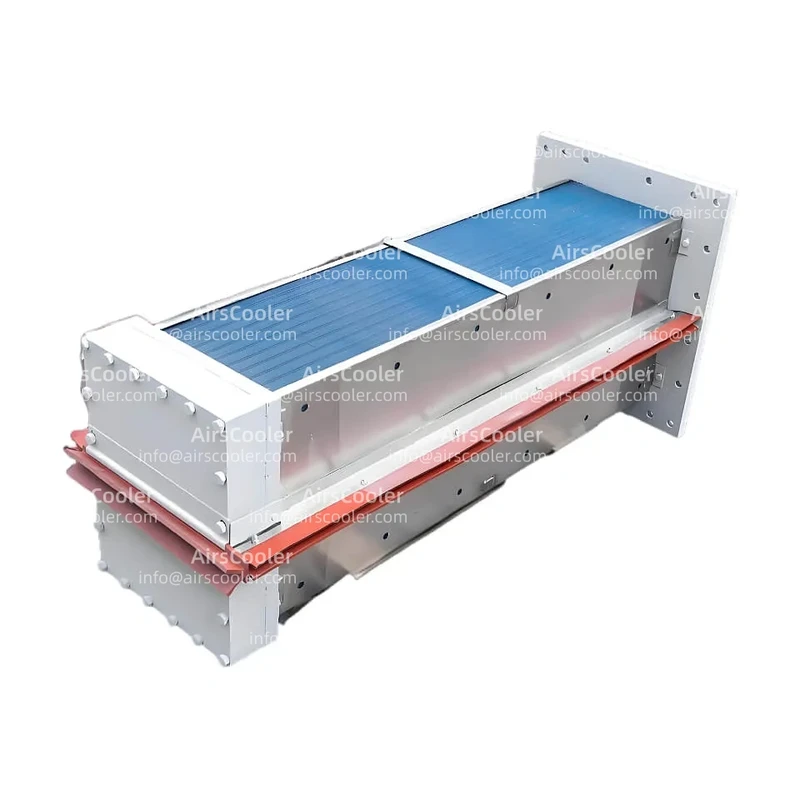

Cooper Joy Compressor AfterCooler

Discover the engineering excellence behind Fete Vessel's industry-leading compressor cooling technology

1. Product Overview: Technical Positioning and Industry Value

The Cooper Joy Compressor AfterCooler serves as the core module in industrial gas compression system setups, performing the critical task of cooling high-temperature compressed air to safe levels. Its technical focus addresses heat accumulation in high-pressure environments, reducing outlet temperatures from 180°C to below 40°C through heat exchange principles.

1.1 Technical Evolution and Industry Standards

Building on AirsCooler's 180+ years of engineering heritage, the product's double-tube pass design with single-shell pass configuration has become the global benchmark in compressor cooling technology, provide 16% higher heat transfer coefficients with 19% less surface area.

1.2 Core Modules and system setup Integration

The TA-2000/Turbo Air 2000 model features:

- Heat Exchange Unit: 316L stainless steel tubes with surface treatment reducing fouling resistance by 40%

- Fluid Distribution: Dual-flow baffle design achieving Reynolds numbers above 10,000

- Support Frame: High-strength carbon steel base meeting IEC 60068-2-6 seismic standards

- Monitoring system setup: PT100 temperature sensors with Modbus RTU protocol support

2. Technical Features with Data-Driven Specifications

2.1 Thermodynamic operational performance Breakthroughs

| Parameter | Value | Industry Advantage |

|---|---|---|

| Heat Transfer Coefficient | 230 W/(m²·℃) | 25% higher than standard |

| pressure loss | <0.02MPa | API 618 compliant |

| Temperature Range | -40℃ to +250℃ | ±50℃/s thermal shock resistance |

2.2 Materials Science use cases

Our engineering offerings include:

- SA-213 TP304H seamless tubes with 0.5mm spiral grooves tripling turbulence

- Inconel 625 alloy cladding passing 1,000-hour salt spray tests

- Combination seals achieving ≤1×10⁻⁹ Pa·m³/s leakage rates

2.3 Smart Control system setups

AirsCooler's intelligent features include:

- PID-controlled water flow with <0.5s response time

- OPC UA protocol for SCADA integration

- Variable flow technology reducing water usage by 35% (12,000 tons/year savings)

3. use case Scenarios and Case Studies

3.1 Industrial Gas Separation

In 12,000Nm³/h air separation plants:

- Humidity reduction from 12g/m³ to 0.3g/m³

- Acetylene removal from 0.8ppm to 0.02ppm

- 75% lower corrosion rates extending maintenance cycles to 24 months

3.2 Semiconductor Manufacturing

For 12-inch wafer fabrication:

- 0.1μm filtration with -70℃ dew point control

- <0.01mm vibration displacement

- ISO 14644-1 Class 1 cleanliness

3.3 Food Processing

In sterile packaging lines:

- 5℃ spray eliminating thermophilic bacteria

- 99.995% oil removal overall efficiency

- 40% steam reduction worth $200k/year

4. Maintenance Strategies

4.1 Preventive Maintenance

AirsCooler recommends:

- Water hardness control below 150ppm

- 0.3ppm polyphosphate inhibitor dosing

- 1.5MPa hydrocleaning with 1.2mm nozzles

4.2 Fault Diagnosis

Our repair protocols address:

- Tube leaks with expansion/welding techniques

- Vibration via stiffness adjustment

- Scaling with EDTA cleaning (>98% removal)

4.3 Digital Operations

Smart monitoring includes:

- Wireless vibration sensors (0-10kHz range)

- Infrared thermography for hot spots

- Digital twin modeling for life prediction

5. Cost-Benefit Analysis

5.1 Lifecycle Costs

TA-2000/Turbo Air 6000 model economics:

- $850k initial investment

- $120k annual power costs (@$0.03/kWh)

- 15% residual value after 15 years

5.2 Environmental Benefits

Per unit annual impact:

- 1,200 tons CO₂ reduction

- 98% water reuse in closed system setups

- <0.5ppm heavy metals in discharge

6. Technology Outlook

Future developments include:

- Silicon carbide tubes targeting 500 W/(m²·℃) coefficients

- 3D-printed channels reducing pressure loss by 25%

- ORC integration achieving 85% energy utilization

As industrial system setups evolve, AirsCooler's Cooper Joy AfterCooler transforms from heat exchange equipment to smart energy nodes, driving global industrial advancement through overall efficiency, intelligence and sustainability.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCooper Joy Compressor Cooler TA11000

View Details

View DetailsCooper Joy Compressor Cooler TA18

View Details

View DetailsCooper Joy Compressor Cooler TA3000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.