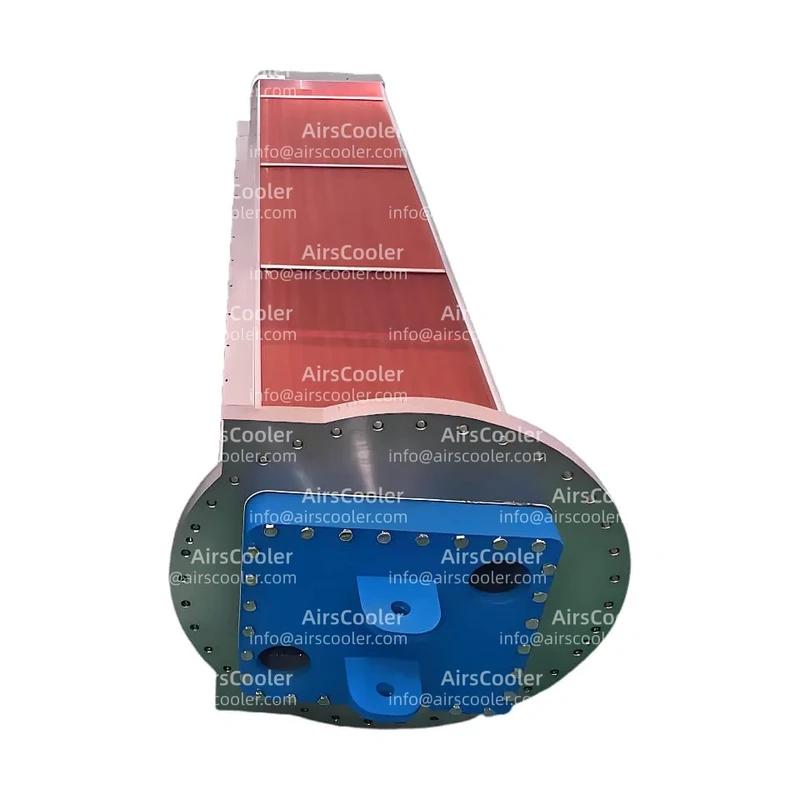

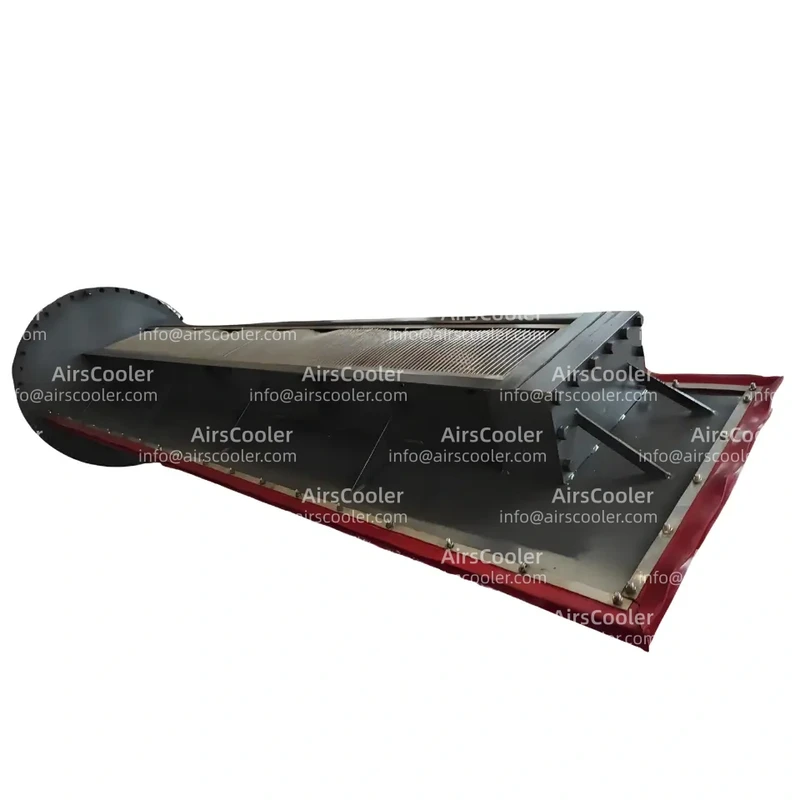

FS-Elliott Compressor Cooler P700

The FS-Elliott P700 is an industrial-grade cooling unit designed for large centrifugal air compressors, delivering exceptional heat exchange performance for continuous production environments.

1. Product Overview: Core Cooling Unit for Compression system setups

The FS-Elliott Compressor Cooler P700 is specifically configured for centrifugal air compressors, performing critical heat transfer to keep stable operating temperatures under ISO 8573-1 Class 0 oil-free standards. As the thermal management hub of compression system setups, this cooler features modular dual-circuit design compatible with single-stage, two-stage, and three-stage compression configurations, with maximum flow capacity reaching 340m³/min (12,000 CFM).

Key modules:

- Dual-stage stainless steel core: Pressure-resistant up to 10.5 barg (150 psig) with laser-welded construction

- Smart temperature control bypass valve: ±0.5℃ precision with automatic cooling water adjustment

- Anti-corrosion coating system setup: NACE MR0175 compliant for sulfur-containing environments

- Redundant cooling circuits: keep 80% capacity during single-circuit failure

2. Technical Specifications & Data

(1) Thermodynamic operational performance Parameters

| Parameter | Value Range | Testing Standard |

|---|---|---|

| Maximum Heat Exchange Capacity | 2,050 kW (2,750 hp) | ASME PTC 12.1 |

| Cooling Water Flow Rate | 150-300 L/min | DIN 1988-500 |

| Inlet Air Temperature Range | -20℃ to +120℃ | ISO 1217:2009 |

| Outlet Temperature Control Precision | ±1.5℃ (full load) | GB/T 3853-2017 |

| Cooling Water pressure loss | ≤50 kPa (full load) | API 617 8th Edition |

(2) Structural Innovations

3D Flow Field Optimization: CFD-designed spiral channels create turbulent flow (Re>10,000) for 25% higher overall efficiency than laminar designs, while keep airside resistance coefficient below 0.18.

Smart Monitoring Module: R1000 control system setup tracks:

- Cooling water flow, temperature, and conductivity

- Core surface temperature gradient

- Fouling thickness (ultrasonic measurement)

Redundant Safety Mechanism: "Dual-core + dual-pump" configuration enables 0.3s circuit switching during leaks, with pressure relief valves activating at 12 barg.

(3) Material & Process Breakthroughs

- Core Materials: 316L stainless steel tubes (2.5mm wall, ≥520 MPa tensile), aluminum-magnesium alloy fins (0.2mm), FFKM seals (-40℃ to +250℃)

- Manufacturing: Vacuum brazing (99.9% joint density), micro-arc oxidation surface treatment (10μm ceramic layer, HV 1,200 hardness)

3. use cases & Case Studies

(1) Core Industries

- Coal Chemical: 35% water savings in Ordos methanol project

- Battery Manufacturing: -40℃ DP air enhances electrode consistency to 99.8%

- Pharmaceutical: 12% penicillin yield increase with oil-free operation

(2) Case Study: Plastic Mold Factory Upgrade

Challenge: 2,400 kW screw compressors with cooling issues caused $150k annual downtime.

offering: 3 P700 centrifugal system setups with heat recovery.

Results: Energy use dropped from 0.12 to 0.085 kW·h/m³, 75% lower maintenance, 7,200 annual operation hours.

4. Maintenance Strategy

(1) Preventive Maintenance

- Daily: Check water flow/temperature/pressure

- Weekly: Surface cleaning (0.5 MPa air)

- Monthly: Record conductivity (≤500 μS/cm)

(2) Troubleshooting Guide

| Symptom | Possible Cause | offering |

|---|---|---|

| High outlet temperature | Core fouling | 5% citric acid cleaning |

| Low water flow | Filter blockage | Replace filter (≤25μm) |

| Core leakage | Weld corrosion | Vacuum brazing repair (≤1×10⁻⁹ helium test) |

(3) overall efficiency Tips

- keep 25-30℃ inlet water (0.8% overall efficiency gain per 1℃ reduction)

- Control water hardness <10 ppm CaCO₃ for 10+ year core life

- Integrate with DCS via Modbus TCP for system setup optimization

5. Conclusion: Industrial Thermal Management Benchmark

The FS-Elliott P700 Cooler redefines industrial thermal standards through material innovation, structural optimization, and intelligent control. Its modular design enables rapid maintenance while redundant architecture help s ensure continuous operation. With carbon reduction capabilities exceeding 2,000 tons/year per unit and upcoming AI predictive maintenance integration, the P700 is positioned as a key enabler for green manufacturing transformation.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsFS-Elliott Compressor InterCooler

View Details

View DetailsFS-Elliott Compressor Oil Cooler

View Details

View DetailsFS-Elliott Compressor Cooler P500

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.