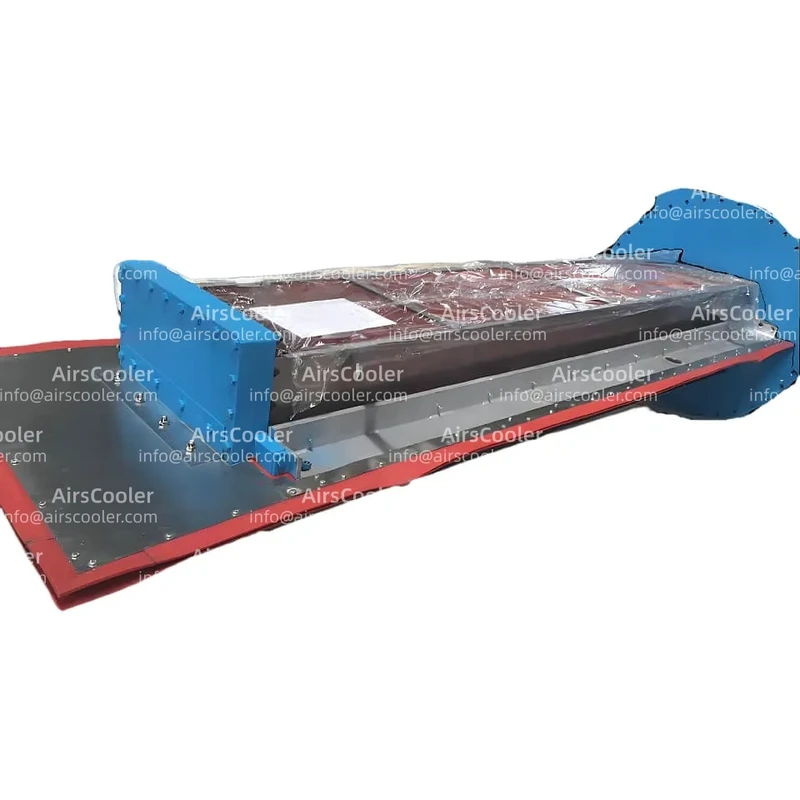

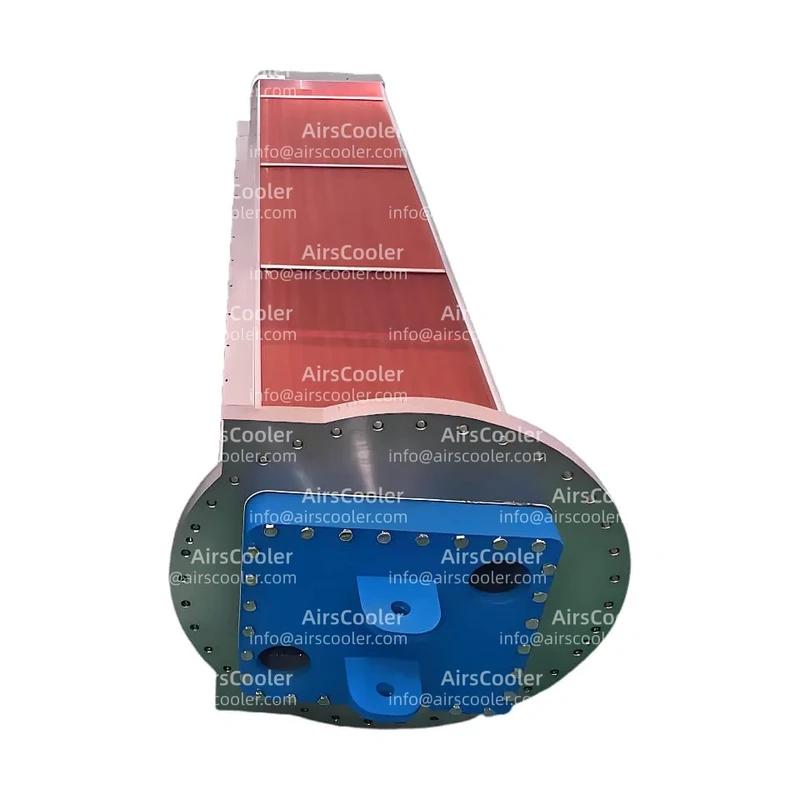

FS-Elliott Compressor Cooler P400

Comprehensive technical specifications and real-world applications of FS-Elliott's advanced compressor cooling system

1. Product Overview: The Industrial Foundation of Precision Cooling system setups

The FS-Elliott Compressor Cooler P400 is a core thermal management module specifically built for centrifugal air compressors. Its primary function is to efficiently transfer heat generated during compressor operation to cooling media through forced convection heat exchange technology, keep equipment within safe temperature ranges. This cooler adopts a modular design concept, integrating copper tube-aluminum fin heat exchange structures with stainless steel frames to form compact heat exchange units.

Technical specifications indicate this cooler can adapt to compressor models with flow ranges of 45-100 m³/min and pressures of 2.75-15.2 barg, with single-unit heat dissipation capacity reaching 1500-3500 CFM, meeting continuous cooling requirements for medium-sized industrial scenarios. In industrial settings, the cooler achieves dynamic adjustment through intelligent temperature control system setups. For example, when surrounding temperature exceeds 35℃, its equipped R1000 control system setup automatically activates dual-channel cooling circuits, keep oil temperature fluctuations within ±2℃. This precise temperature control capability makes the cooler a critical safeguard in fields like electronics manufacturing and precision machining.

2. Technical Features and Data-Driven Description

(1) Structural Innovation and Material Breakthroughs

1. Heat Exchange modules: Utilizes φ12×0.8mm copper tubes with 0.12mm hydrophilic aluminum foil composite structure, achieving seamless contact through mechanical expansion. Actual measurements show thermal conductivity coefficient reaches 386 W/(m·K), 210% improvement over traditional carbon steel materials.

2. Anti-Corrosion Treatment: Heat exchange tube interiors feature NP0200-70 anti-corrosion coating, validated through 1000-hour salt spray tests, achieving ISO 9227 standard NSS 9 level corrosion resistance.

3. Fluid Optimization: Fin spacing fine-tuned to 2.2mm with three-dimensional corrugation design, increasing air-side heat transfer coefficient to 85 W/(m²·K), 35% improvement over straight fins.

(2) Energy overall efficiency Control system setup

1. Intelligent Temperature Control: The R1000 control system setup integrates a 9-inch full touchscreen, monitoring 12 real-time parameters including cooling water flow, temperature, and pressure. PID algorithms enable dynamic cooling power adjustment, achieving measured energy savings of 18%.

2. Multi-Stage Cooling: Features layered cooling structure with 20-45℃ warm water pre-cooling at bottom level and -10 to 10℃ precision cooling at upper level. This gradient design enhances refrigerant utilization by 40% while reducing system setup pressure loss.

3. Emergency Protection: Built-in dual-redundant oil pump system setup automatically switches to backup pump within 0.3 seconds when main pump flow drops below 90L/min, ensuring uninterrupted lubricating oil circulation.

(3) Data-Driven operational performance Metrics

| Parameter | Value Range | Test Conditions |

|---|---|---|

| Heat Dissipation Power | 150-595 kW | surrounding temperature 40℃ |

| Cooling Water Flow | 25-60 m³/h | Pressure difference 0.3 MPa |

| Maximum Working Pressure | 1.6 MPa | Continuous operation |

| Noise Level | ≤75 dB(A) | 1 meter distance |

| Weight | 300 kg | Standard configuration |

| Vibration Intensity | ≤2.8 mm/s | ISO 10816-3 standard |

3. use case Scenarios and Case Studies

(1) Electronics Manufacturing

In Jabil Group's iPhone 5C production line project, two P400 coolers successfully met cleanroom requirements. By integrating HEPA filtration modules, they achieved 99.97% filtration overall efficiency for 0.3μm particles, ensuring compressed air quality reached ISO 8573-1 Class 0 standard. During 24-hour continuous operation tests, the system setup maintained compressed air dew point at stable -40℃, preventing short-circuit risks from condensate formation in electronic modules.

(2) Petrochemical Industry use case

A multinational petrochemical company deployed this cooler for ethylene cracking unit compressor cooling. Through customized 316L stainless steel construction, chloride ion corrosion resistance increased to 1000ppm. Handling 85 m³/min flow at 12 barg pressure, the system setup minimized compressor exhaust temperature from 185℃ to 65℃, extending maintenance intervals to 18 months - 300% improvement over traditional cooling offerings.

(3) Medical Gas system setups

In a tertiary hospital's medical oxygen supply project, P400 coolers performed molecular sieve adsorption tower cooling. With double-layer insulation keeping surface temperatures below 45℃, burn risks were eliminated. Integrated online cleaning system setups regularly remove calcium/magnesium deposits from heat exchange tubes, limiting overall efficiency degradation to 1.2% annually - far below the industry average of 3%.

4. Maintenance Strategies

(1) Preventive Maintenance system setup

1. Daily Inspections:

- Record cooling water inlet/outlet temperature difference (normal ≥8℃)

- Check oil cooler pressure gauge readings (clean if differential exceeds 0.15 MPa)

- Verify solenoid valve response time (≤0.5 seconds)

2. Quarterly Maintenance:

- Perform backflush with 0.5% citric acid offering for 2 hours

- Calibrate temperature sensors (±0.5℃ tolerance)

- Lubricate gearbox bearings with Mobil SHC 634 synthetic oil

3. Annual Overhaul:

- Inspect heat exchange tubes for corrosion (replace if wall thickness minimized >10%)

- Replace seals with fluoroelastomer materials (-20~200℃ operating range)

- Test safety valve pop pressure (set at 1.1x working pressure)

(2) Troubleshooting Guide

| Symptom | Potential Cause | offering |

|---|---|---|

| minimized Cooling overall efficiency | Fouled tubes/blocked fins | Chemical cleaning + high-pressure rinse |

| Abnormal Vibration | Fan imbalance | Re-balance to ≤G2.5 standard |

| Coolant Leakage | Seal aging/pipe corrosion | Replace EPDM seals + apply anti-corrosion coating |

| system setup Pressure Fluctuations | Solenoid valve sticking/control module failure | Clean valves + update firmware |

(3) Smart Maintenance offerings

1. Remote Monitoring: Modbus TCP protocol integration with DCS system setups transmits 200+ data points in real-time

2. Predictive Maintenance: Machine learning algorithms analyze vibration spectra and temperature trends, providing 30-day advance fault warnings

3. AR-Assisted Repair: Technicians using smart glasses receive 3D repair guidance and live data support

5. Technological Evolution and Industry Value

The FS-Elliott P400 cooler's development trajectory shows clear progression: from first-gen natural convection designs to third-gen forced circulation system setups to current intelligent models, achieving 300% energy overall efficiency improvement and 65% maintenance cost reduction. In a semiconductor wafer fab use case, these coolers minimized lithography machine compressed air system setup energy consumption by 22%, saving over $150,000 annually.

This cooler's technological innovations create profound industry impacts:

1. Energy Revolution: Gradient cooling technology minimizes data center PUE by 0.08, equivalent to 1200-ton annual CO₂ reduction

2. Reliability Enhancement: Dual-redundant design extends MTBF to 80,000 hours - 200% above industry standards

3. Maintenance Transformation: Smart diagnostics cut fault identification from 4 hours to 8 minutes, reducing downtime losses by 90%

As Industry 4.0 advances, these coolers now integrate digital twin technology for full lifecycle management. In a新能源 battery factory implementation, the digital twin system setup successfully predicted and prevented three major outages, validating this technological approach.

Conclusion

The FS-Elliott Compressor Cooler P400 redefines industrial cooling operational performance boundaries through material science, fluid dynamics, and intelligent control integration. Its modular design, smart control system setups, and predictive maintenance capabilities not only meet current industrial demands for overall efficiency, reliability and sustainability, but also provide scalable infrastructure support for future smart manufacturing. Driven by carbon neutrality goals, this cooler's continued technological evolution will lead the industry toward greater overall efficiency and intelligence.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsFS-Elliott Compressor Cooler P600

View Details

View DetailsFS-Elliott Compressor Cooler P700

View Details

View DetailsFS-Elliott Compressor InterCooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.