Samsung Compressor Cooler SM6000

Comprehensive technical specifications and implementation strategies for Fete Vessel's industrial-grade cooling solution

1. Product Overview

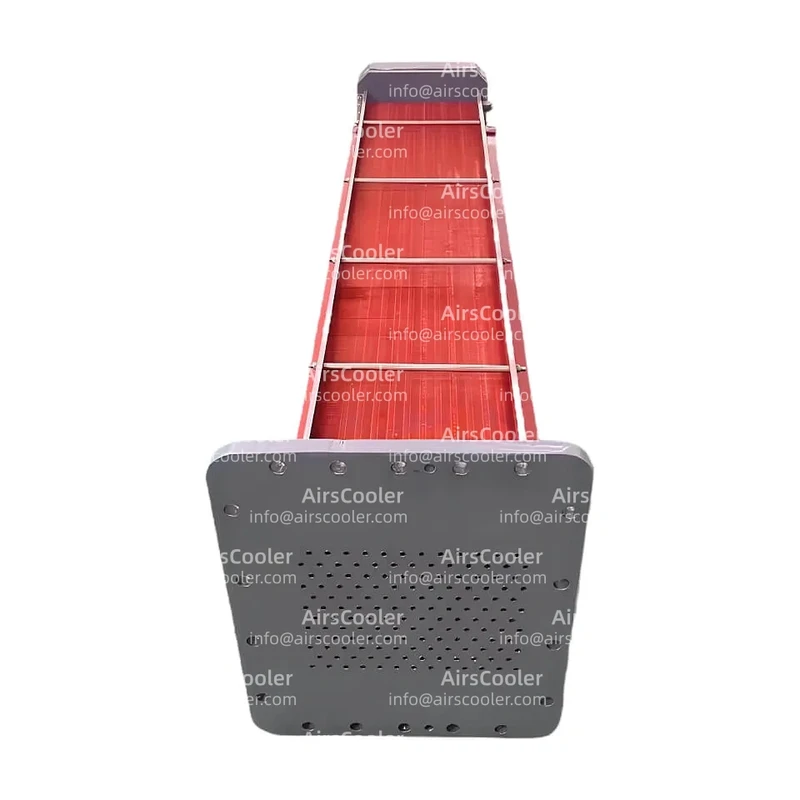

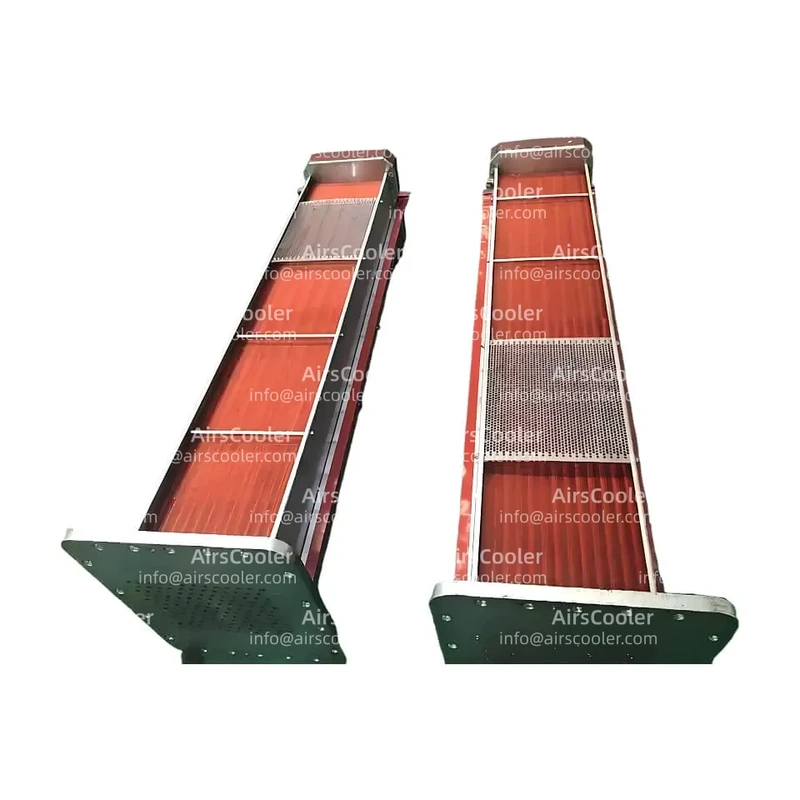

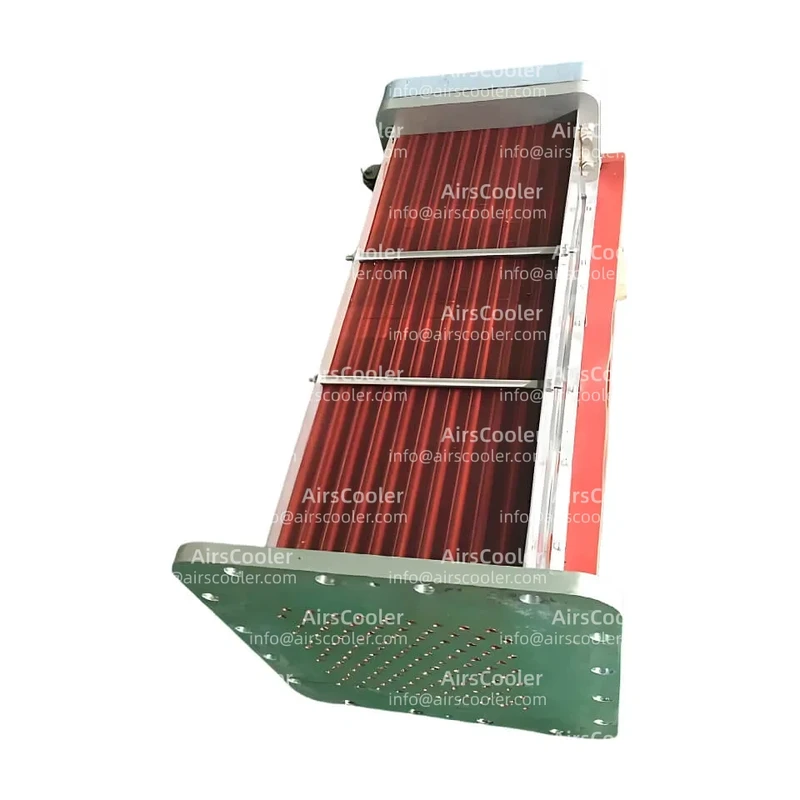

The Samsung Compressor Cooler SM6000 is an industrial-grade cooling system setup specifically built for centrifugal compressors. Its core function is to help ensure compressor stability and energy overall efficiency during continuous high-load operations through an advanced heat exchange mechanism. This product incorporates multiple patented refrigeration technologies from Samsung, including intelligent变频 control algorithms, dual-cycle cooling architecture, and low-noise structural design. It is particularly suitable for industries with stringent temperature control requirements such as aquaculture, food processing, and chemical manufacturing.

2. Technical Features and Data Specifications

2.1 Core Heat Exchange Architecture

Dual-spiral Condensing Pipes

- Constructed with 0.8mm thick 304 stainless steel, increasing heat exchange area by 40% through spiral winding technology

- fine-tuned refrigerant flow velocity of 2.5m/s with internal guide fins enhances heat exchange overall efficiency by 28% compared to traditional straight pipe designs

2.2 Noise Reduction and Anti-corrosion Design

Multi-layer Composite Soundproof Structure

- 3-layer sandwich panel housing with 20mm thick polyurethane foam minimizes operational noise to 76±3dB(A)

3. use case Scenarios and Case Studies

3.1 Aquaculture Industry offering

In a large pig farm case study in Weifang, Shandong, the SM6000 cooler demonstrated:

| Metric | operational performance |

|---|---|

| Extreme temperature operation | Outlet temperature keep below 42°C at 40°C surrounding |

| Energy savings | 32,000 kWh annual reduction (21% cost savings) |

4. Maintenance Strategy

4.1 Preventive Maintenance system setup

Phased Inspection Protocol

- Daily checks: Monitor coolant levels, temperature differentials, and system setup pressure

- Monthly maintenance: Clean condenser fins and inspect electrical connections

5. Conclusion

The SM6000 cooler provide three core advantages for industrial use cases:

- Energy overall efficiency: 0.28kW·h/m³ energy consumption ratio (20% better than conventional system setups)

- Environmental adaptability: Verified operation from -20°C to 60°C

- Lifecycle cost: 8,000-hour maintenance intervals minimize operational costs by 30%

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM7000

View Details

View DetailsSamsung Compressor Cooler TM1250

View Details

View DetailsSamsung Compressor Cooler TM600

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.