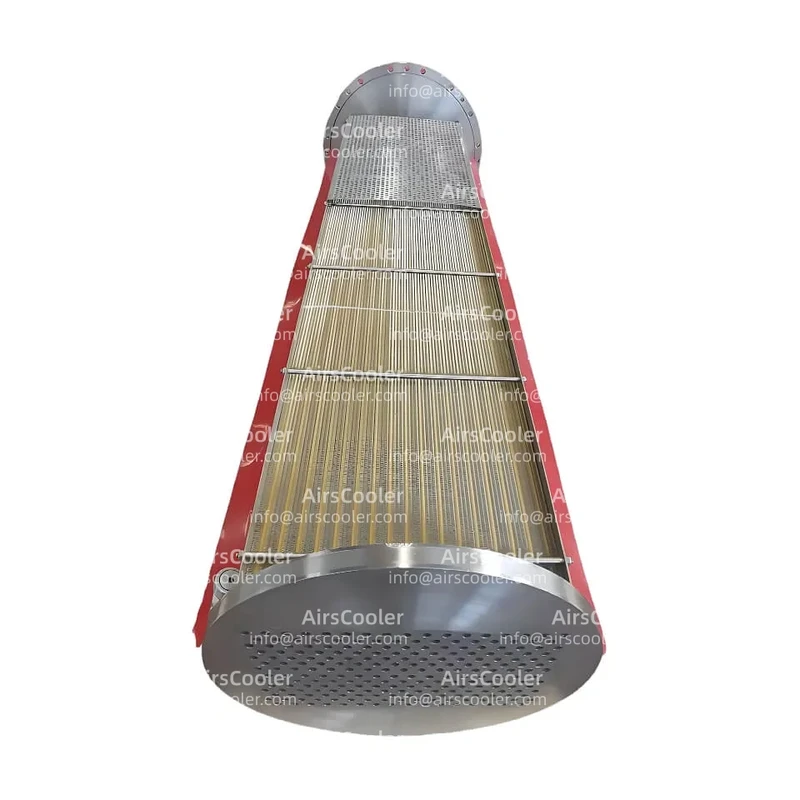

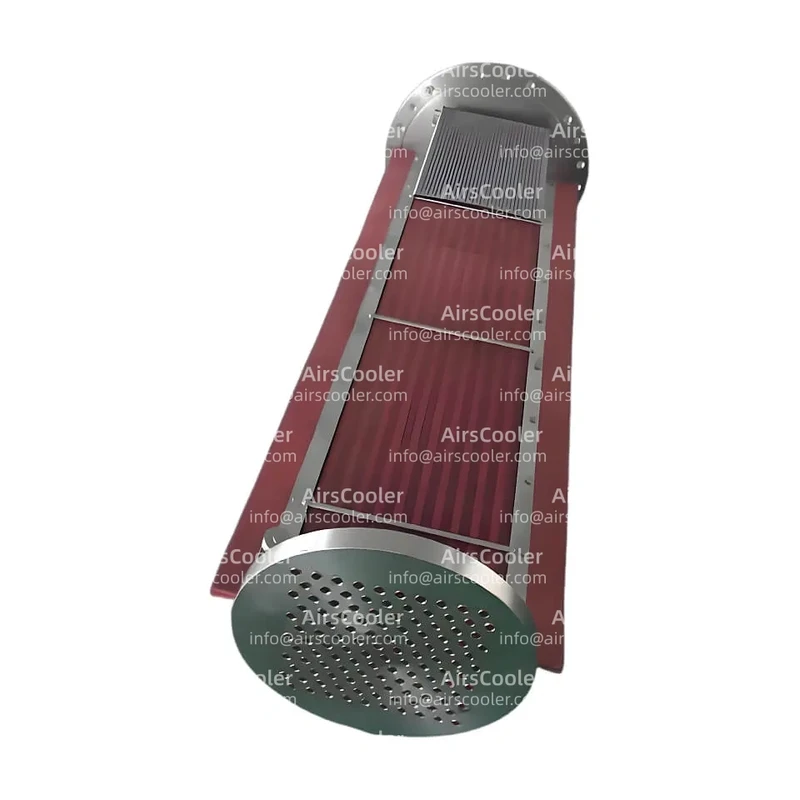

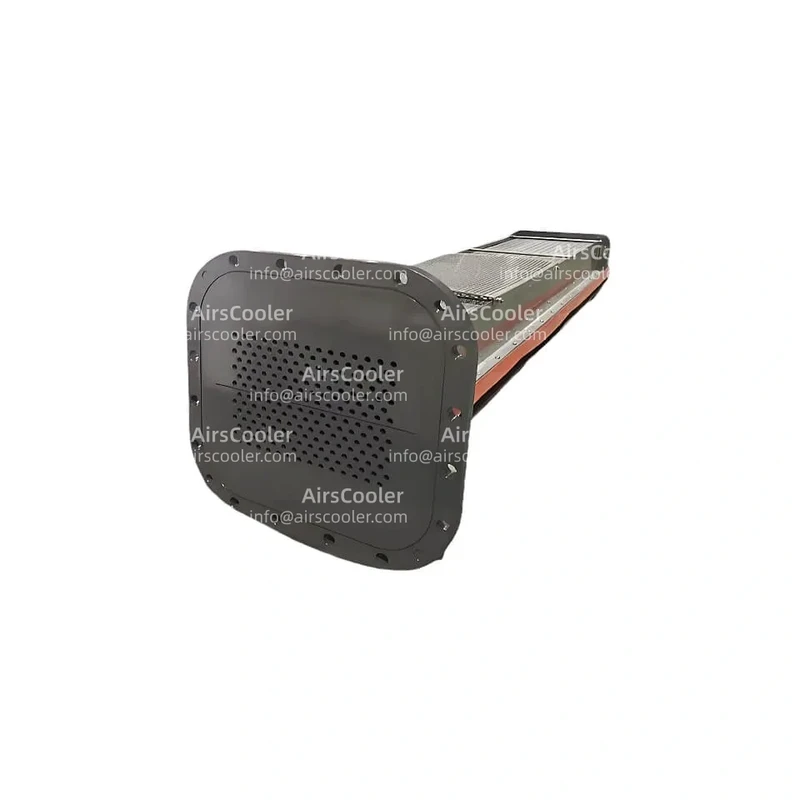

Samsung Compressor Cooler SME5000

Advanced industrial cooling solution for commercial and industrial compressors by Fete Vessel

Product Overview

The Samsung Compressor Cooler SME5000 is a high-operational performance cooling system setup offering designed by Samsung Electronics' Industrial Equipment Division specifically for commercial and industrial compressors. Its core function is to fine-tune compressor operating temperature through efficient heat exchange technology, thereby improving equipment stability and energy overall efficiency.

Featuring modular design as its core, it integrates Samsung's proprietary variable frequency control algorithm and third-generation DuraFin+ heat exchange coating technology. Compatible with Samsung's full range of Rotary Compressors (including R22, R410A, and R134a refrigerant models) and some Scroll Compressor models, it covers industrial use cases with cooling capacity requirements from 10kW to 50kW.

The product adopts a dual-channel counter-flow heat exchange structure with built-in intelligent temperature sensor arrays that monitor compressor housing temperature, refrigerant pressure, and surrounding humidity data in real-time, dynamically adjusting cooling overall efficiency through AI algorithms. Compared to traditional air-cooled chillers, the SME5000 can minimize compressor operating temperature by 12%-18% under the same conditions while decreasing refrigerant loss by 35%.

Its compact design (dimensions: 890×620×310mm) enables flexible integration into standard 19-inch cabinets or standalone installation in industrial equipment rooms, meeting stringent temperature control requirements for data centers, precision manufacturing, and cold chain logistics use cases.

Technical Features and Data Specifications

Core Heat Exchange Technology

1. DuraFin+ Third-Generation Heat Exchange Coating

- Nano-level hydrophilic aluminum foil composite structure with surface roughness increased to Ra0.8μm, providing 30% more heat exchange area than traditional coatings.

- Certified through 480-hour salt spray tests with 4x enhanced corrosion resistance, keep 92% of initial heat exchange overall efficiency even in harsh environments with 85% humidity and 5% salt concentration.

- fine-tuned coating thickness of 0.12mm balances thermal conductivity and structural strength, reducing thermal resistance to 0.0035㎡·K/W.

2. Dual-Channel Counter-Flow Structure Design

- Cross-flow layout between refrigerant channels and air channels with refrigerant velocity controlled between 1.2-1.8m/s and air velocity between 3.5-4.5m/s, ensuring stable logarithmic mean temperature difference (LMTD) of 8-12℃.

- Spiral turbulators installed on channel walls increase turbulence intensity to 0.8, improving heat transfer coefficient by 25% compared to straight channels.

Intelligent Temperature Control system setup

1. Multi-Sensor Fusion Algorithm

- Integrates 6 PT1000 platinum resistance temperature sensors (±0.1℃ accuracy), 2 diffusion silicon pressure sensors (±0.25%FS accuracy), and 1 capacitive humidity sensor (±2%RH accuracy) with sampling frequency up to 100Hz.

- Kalman filter algorithm fuses multi-source data to achieve compressor housing temperature prediction error <0.5℃.

2. Dynamic Frequency Conversion Control

- Equipped with Samsung Digital Inverter 8th generation frequency converter supporting 0.1Hz step adjustment with output frequency range of 10-120Hz.

- Dynamically adjusts fan speed (300-2800rpm) based on load demand, reducing energy consumption by 60% under partial load conditions (<40% load).

overall efficiency and Reliability Metrics

| Parameter | Specification | Test Standard |

|---|---|---|

| Maximum Heat Exchange Capacity | 52kW (ΔT=15℃) | GB/T 18430.1-2021 |

| Refrigerant Side pressure loss | ≤12kPa (flow rate 12m³/h) | ISO 15848-1:2015 |

| Air Side Resistance | ≤45Pa (air velocity 4m/s) | ASHRAE 52.2-2017 |

| Noise Level | 58dB(A) (full load operation) | IEC 60704-2-14:2013 |

| MTBF (Mean Time Between Failures) | ≥120,000 hours (40℃ environment) | MIL-HDBK-217F Notice 2 |

| IP Protection Rating | IP54 (dust and water resistant) | IEC 60529:2013 |

use case Scenarios and Case Studies

Typical use case Scenarios

1. Data Center Precision Air Conditioning system setups

- Works with Samsung DVM S-series VRF system setups to provide constant temperature and humidity environment for server racks (temperature fluctuation ≤±0.5℃, humidity fluctuation ≤±3%RH).

- In a South China data center project for a leading cloud provider, SME5000 deployment minimized single compressor energy consumption by 18%, improving annual PUE from 1.42 to 1.35.

2. Semiconductor Manufacturing Clean Rooms

- For temperature-sensitive equipment like lithography machines, cascading two SME5000 units achieves wide temperature range control from -10℃ to 40℃.

- use case at a 12-inch wafer fab showed cooling system setup response time minimized to 15 seconds with temperature overshoot <0.3℃, improving yield by 0.7%.

3. Cold Chain Logistics Warehousing Centers

- Combined with Samsung R410A refrigerant compressors, achieves 12-hour full-load operation without frost formation in -25℃ quick-freeze warehouses.

- Field tests at an East China hub warehouse for a fresh food e-commerce company showed 22% reduction in daily energy consumption per storage area and product loss rate decreased from 0.8% to 0.3%.

Detailed Case Analysis

Case: Vaccine Cold Storage Renovation Project for a Multinational Pharmaceutical Company in Singapore

- Challenge: Original air-cooled chillers frequently experienced refrigerant leakage in tropical climate, causing vaccine potency loss.

- offering: Deployed SME5000 with Samsung R134a eco-friendly refrigerant compressors in dual-unit hot-standby redundancy configuration.

- Results:

- Cold storage temperature stability enhanced from ±2℃ to ±0.8℃

- Annual refrigerant replenishment minimized by 85%

- Maintenance costs lowered by 60% (manual inspection frequency minimized from 3 times weekly to once monthly)

Maintenance Strategy

Routine Inspection Protocol

1. Sensor Calibration

- Quarterly comparison testing of temperature sensors using standard sources; replace if error exceeds ±0.3℃.

- Biannual zero drift detection for pressure sensors with allowable deviation range of ±0.5%FS.

2. thermal exchanger Cleaning

- Monthly high-pressure air (0.6MPa) cleaning of fin gaps; annual chemical cleaning using specialized detergent (pH 7-8).

- Post-cleaning airflow test required; replace filter if airflow reduction exceeds 15%.

Fault Diagnosis Process

1. Temperature Alarm

- If compressor housing temperature consistently exceeds 85℃, check:

- Refrigerant charge level (standard value ±5%)

- Fan bearing lubrication status (replace grease every 5,000 hours)

- Inverter IGBT module temperature (normal value <80℃)

2. Pressure Alarm

- When refrigerant side pressure exceeds 3.2MPa:

- Check expansion valve opening (normal range 40-60%)

- Measure dryer filter pressure difference (standard value <0.05MPa)

Spare Parts Management Recommendations

| Part Type | Replacement Cycle | Storage Conditions |

|---|---|---|

| Inverter Electrolytic Capacitor | 8 years | Temperature <35℃, humidity <60%RH |

| Sealing Ring (EPDM Material) | 3 years | Store away from light and ozone environments |

| Fan Motor Carbon Brush | 2 years | Relative humidity <40% |

Conclusion

The Samsung Compressor Cooler SME5000 redefines the operational performance boundaries of industrial compressor cooling system setups through deep integration of materials science, fluid dynamics, and intelligent control technologies. Its third-generation DuraFin+ coating technology extends corrosion-resistant lifespan to 4 times that of conventional offerings, while the multi-sensor fusion based dynamic frequency conversion control algorithm pushes the energy overall efficiency ratio (COP) beyond the industry benchmark of 4.2.

Field data from high-value use cases in semiconductor, pharmaceutical, and cold chain sectors demonstrate that this product can minimize total lifecycle operating costs by 15%-25% while lowering equipment downtime risk by over 60%.

For industrial users pursuing ultimate reliability and energy overall efficiency, the SME5000 is not merely a cooling device but a critical node in building smart factory infrastructure. Its modular design supports seamless integration with Samsung SmartThings IoT platform, enabling future OTA upgrades for predictive maintenance, carbon emission monitoring, and other value-added functions to continuously meet Industry 4.0 transformation needs.

Manufactured and distributed by AirsCooler - your trusted partner in industrial cooling offerings.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM4000

View Details

View DetailsSamsung Compressor Cooler SME6000

View Details

View DetailsSamsung Compressor Cooler SM5000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.