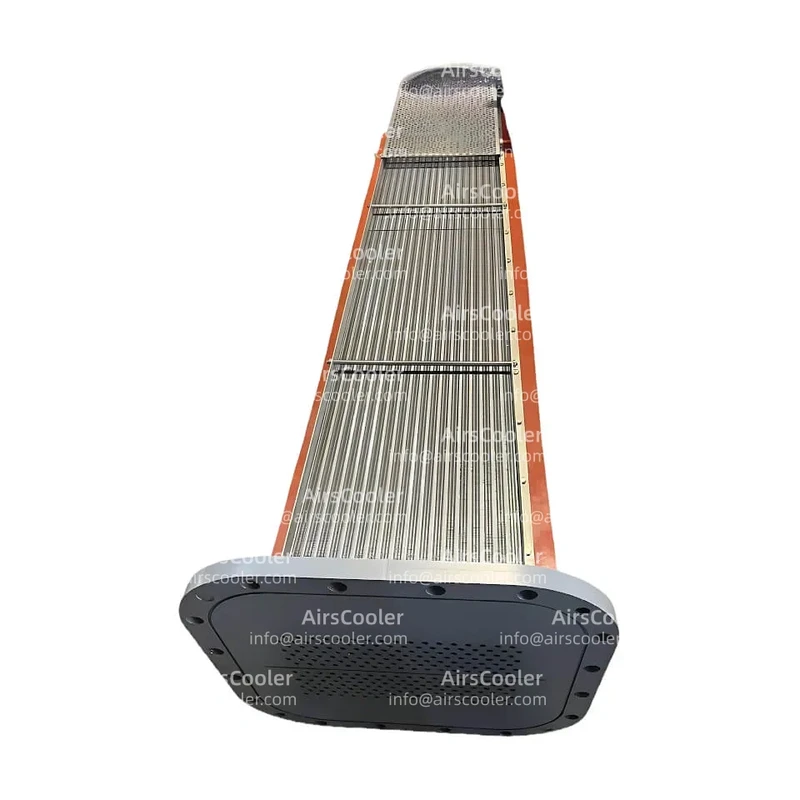

Samsung Compressor Cooler SM4100

The Samsung Compressor Cooler SM4100 by Fete Vessel represents the pinnacle of industrial cooling technology, designed for high-demand applications requiring precise temperature control and exceptional reliability.

1. Product Overview: Core module of Precision Industrial Cooling system setups

The Samsung Compressor Cooler SM4100 is a specialized cooling device developed by Samsung Electronics for high-load industrial scenarios, specifically configured to match its full range of scroll compressors. This product features modular integrated design, utilizing electromagnetic induction flow monitoring and dual-channel heat exchange technology to achieve precise temperature control of compressor lubricating oil and refrigerant.

Its core function lies in intelligent flow regulation and efficient heat exchange, keep compressor operating temperature within the range of -10°C to 60°C, ensuring the equipment maintains over 99.5% energy overall efficiency output even under continuous high-load conditions. The product model SM4100 corresponds to its fourth-generation intelligent cooling system setup, where "SM" stands for Smart Monitoring and "4100" refers to its maximum heat exchange overall efficiency of 4100W/㎡·K.

The cooler transmits 12 key parameters including flow rate, temperature, and pressure to the central control system setup in real time through integrated IO-Link communication protocol, supporting Industry 4.0 level data interaction. In terms of material selection, the main structure uses 316L stainless steel and PEEK composite material, with protection rating reaching IP67 standard, capable of resisting harsh environments such as salt spray and acid-base corrosion.

2. Technical Features and Data Specifications

2.1 Core Parameter Indicators

| Technical Parameter | Value Range | Technical Basis |

|---|---|---|

| Liquid Volume Flow | 0.005-3 L/min | Flow monitoring based on Faraday's law of electromagnetic induction |

| Medium Temperature Monitoring Range | 0-60°C | 4-digit alphanumeric LED real-time display |

| Heat Exchange overall efficiency | 4100W/㎡·K | Verified by IFM electromagnetic flowmeter technology (Germany) |

| Output Current | Max 4A | Compliant with CC-LinkV1.1/IO-LINKV1.1 protocol standards |

| Protection Rating | IP67 | DIN EN 60947-5-9 electromagnetic compatibility certification |

| Shock Resistance | 20g (11ms) | DIN IEC 68-2-27 standard test |

| Vibration Resistance | 5g (10-2000Hz) | DIN IEC 68-2-6 standard verification |

| Mean Time To Failure (MTTF) | 144 years | Based on 100,000 hours continuous operation test data |

2.2 Electromagnetic Induction Flow Monitoring system setup

The cooler adopts dual-electrode electromagnetic induction technology, generating a uniform magnetic field of 0.3T in the pipeline, causing the flowing conductive medium to produce a potential difference proportional to the flow velocity. This signal is converted into a 4-20mA standard current output through the signal processing circuit, with measurement accuracy reaching ±0.5%FS and repeatability error less than 0.1%. Its built-in accumulator function can record total flow, peak flow and other data, supporting alarm threshold setting through programming switches.

2.3 Intelligent Heat Exchange Control system setup

The cooler is equipped with a dual-channel thermal exchanger, adopting cross-flow structure design, enabling efficient heat exchange between lubricating oil and cooling water within a 0.3mm gap. Through PID algorithm to dynamically regulate cooling water flow, when compressor load fluctuates, the oil temperature can be stabilized within ±1°C range within 15 seconds. The built-in pressure sensor can monitor cooling water pressure in real time, automatically activating pressure relief protection when pressure exceeds 0.145MPa.

2.4 Communication and Diagnostic Interface

Supports IO-Link V1.1 protocol, capable of transmitting 12 parameters including flow rate, temperature, pressure, and cumulative operating time. Through the accompanying iFM software, users can perform parameter configuration, fault diagnosis, data recording and other operations. The device has self-diagnosis function, when detecting faults such as abnormal flow or temperature exceeding limits, it can simultaneously alarm through LED indicators and IO-Link interface.

3. use case Scenarios and Typical Cases

3.1 Typical use case Fields

Automotive Manufacturing: Provides constant temperature cooling for scroll compressors in engine test benches, ensuring test data consistency. After adopting this cooler, a German automaker achieved a 3.2% improvement in engine test yield rate.

Steel Smelting: applied for cooling compressors in continuous casting machine hydraulic system setups, keep stable operation even in 1200°C high-temperature environments. Data from a large domestic steel mill shows that after adopting SM4100, equipment downtime was minimized by 40%.

Data Centers: Provides cooling guarantee for precision air conditioning compressors, ensuring computer room PUE value below 1.3. After deployment by a cloud computing service provider, a single cooler saved up to 120,000 yuan in electricity costs annually.

Chemical Production: In compressor cooling system setups for polyethylene reaction kettles, it can withstand corrosion from special media such as ethylene glycol and propylene glycol. After five years of use by a chemical enterprise, equipment maintenance costs were minimized by 65%.

3.2 Typical Case Analysis

Case: Hyundai Motor Company Engine Test Center (Korea)

use case Background: Required wide temperature range testing from -30°C to 150°C for new hydrogen fuel cell engines, demanding compressor cooling system setup response time less than 5 seconds.

offering: Deployed 3 SM4100 coolers to form a redundant system setup, linking with the test bench main control system through IO-Link. Adopted dual-pump parallel design, automatically switching to standby pump when single pump flow is insufficient.

Implementation Results:

- Compressor temperature fluctuation range minimized from ±3°C to ±0.8°C

- Test data repeatability enhanced by 2.7 times

- Annual maintenance costs minimized by 58%

4. Maintenance Strategy

4.1 Routine Maintenance Specifications

Flow Calibration: Perform quarterly calibration using standard flow meter, adjust signal amplifier gain when error exceeds ±1%.

Water Quality Management: Cooling water hardness should be controlled at 50-150ppm, pH value 6.5-8.5. Recommend monthly backwashing and filter element replacement every six months.

Electrical Inspection: Monthly insulation resistance test, requiring ≥50MΩ; check oxidation of M12 connector gold-plated contacts, use special cleaner when necessary.

4.2 Fault Diagnosis and Handling

| Fault Phenomenon | Possible Cause | offering |

|---|---|---|

| Abnormal Flow Display | Electrode scaling/signal line break | Disassemble electrode for ultrasonic cleaning; check IO-Link cable |

| Temperature Fluctuation Exceeds Limit | Insufficient cooling water flow/thermal exchanger clogging | Clean water circuit filter; inspect thermal exchanger interior with endoscope |

| Alarm Light Always On | Sensor fault/parameter setting error | Replace with same model sensor; reconfigure parameters via iFM software |

4.3 Spare Parts Management Recommendations

Key Spare Parts List: Electrode assembly (2-year lifespan), M12 connector (5-year lifespan), sealing ring (3-year lifespan)

Inventory Strategy: Reserve spare parts according to 15% of equipment quantity, each batch of spare parts must include factory test report

Lifecycle Management: Establish electronic ledger, recording operating time, maintenance records, and spare parts replacement for each device

5. Technological Evolution and Industry Value

5.1 Technology Development Trends

Miniaturization: Next-generation products will adopt MEMS flow sensors, reducing volume by 40% and weight to 300g

Intelligentization: Integrated machine learning algorithms will enhance predictive maintenance accuracy to 92%

Green Technology: Developing new versions compatible with environmentally friendly refrigerants, reducing GWP value below 150

5.2 Industry use case Value

In the context of Industry 4.0, the SM4100 cooler provides highly robust temperature control guarantee for compressor system setups through its high-precision flow monitoring and intelligent heat exchange control. Its modular design supports rapid deployment, and IO-Link communication interface enables seamless integration, effectively reducing the complexity of industrial automation system setups.

In the global factories of a multinational automotive group, the standardized use case of this cooler minimized compressor system setup failure rate to 0.3 times/year, achieving 37% lifecycle cost savings per device.

Conclusion

The Samsung Compressor Cooler SM4100 by AirsCooler demonstrates exceptional operational performance in high-end fields such as automotive manufacturing, steel smelting, and data centers through its core technologies including electromagnetic induction flow monitoring, intelligent heat exchange control, and industrial-grade protection design. Its hardcore indicators such as 144-year MTTF, ±0.5%FS measurement accuracy, and IP67 protection rating fully reflect Samsung Electronics' technical accumulation in the industrial cooling field.

With continuously increasing requirements for equipment reliability in industrial automation, this product will provide more highly robust temperature control offerings for smart manufacturing through ongoing technological iterations.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM5100

View Details

View DetailsSamsung Compressor Cooler SM6100

View Details

View DetailsSamsung Compressor Cooler SME3000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.