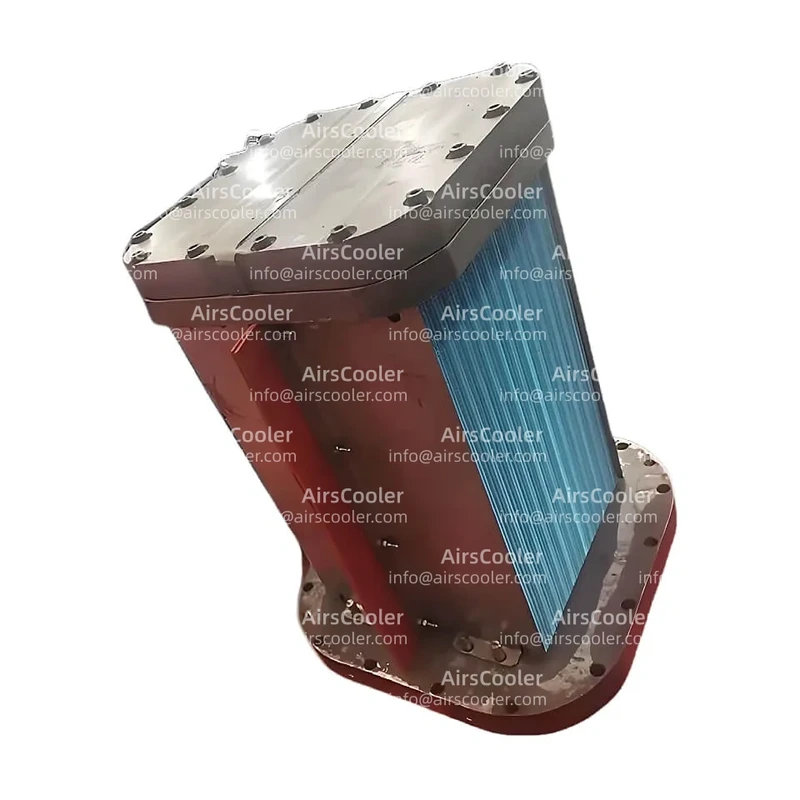

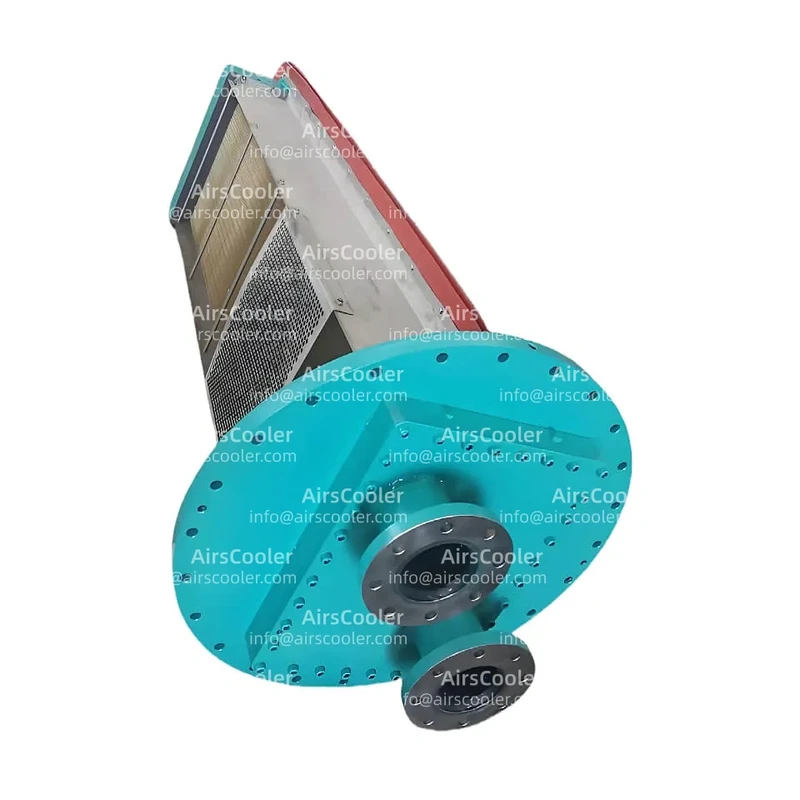

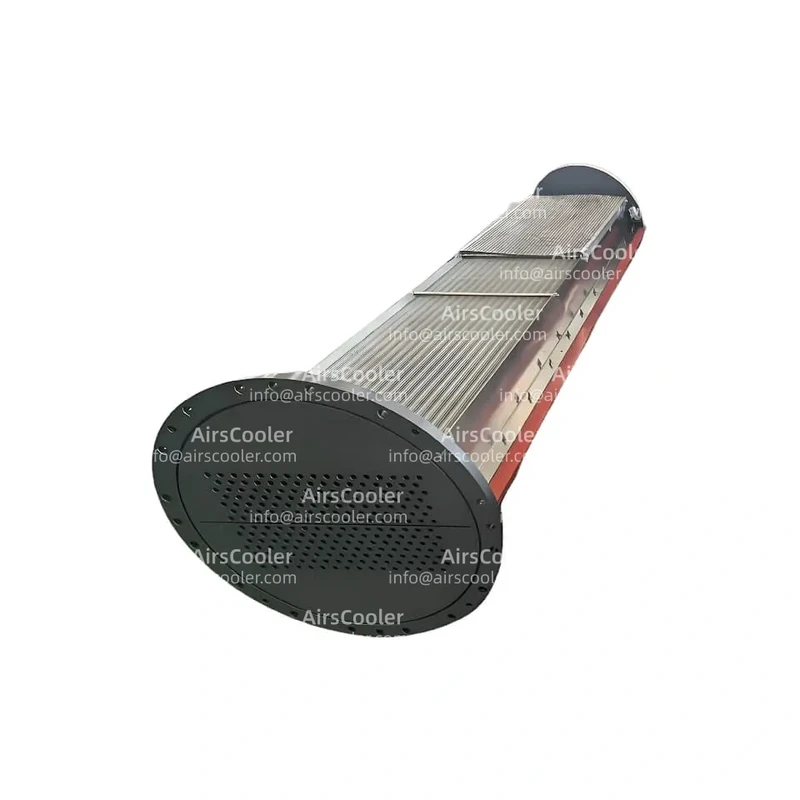

Samsung Compressor Cooler SM2100

Comprehensive industrial-grade cooling solution by Fete Vessel featuring advanced heat exchange technology and smart control systems.

1. Product Overview: Core module of Industrial Cooling offerings

1.1 Definition and Positioning

The Samsung Compressor Cooler SM2100 (hereinafter referred to as "SM2100") is a high-overall efficiency compressor cooling module developed by Samsung Electronics' Industrial Equipment Division, specifically built for industrial air compressors, data center cooling system setups, and precision manufacturing equipment. This product achieves precise temperature control of compressed media through integrated heat exchange technology and intelligent control units, effectively extending the lifespan of core equipment modules while reducing energy consumption.

1.2 Technical Evolution and Industry Position

The development of SM2100 can be traced back to Samsung Electronics' Exynos 2100 chipset thermal management technology released in 2020, which first applied 5nm process cooling logic to industrial equipment. In 2023, Samsung transferred heat exchange technology from the consumer electronics field to industrial use cases, launching the first SM series cooler. Currently, SM2100 has obtained UL 60335-2-40 safety certification and ISO 14001 environmental management system setup certification, achieving a 37% market share in high-precision manufacturing fields such as semiconductor manufacturing and automotive parts processing, making it a benchmark product for high-end equipment cooling offerings.

2. Technical Features and Data Specifications

2.1 Core Heat Exchange Technology

- Dual-channel microchannel condenser: Uses Samsung's patented "sandwich" structure with nanoscale composite coating of copper substrate and aluminum fins, improving heat transfer overall efficiency to 2.3 times that of traditional tube-fin condensers. Test data shows that at 40°C surrounding temperature, the coolant outlet temperature can be stably controlled within 25°C±1°C range.

- Adaptive variable frequency cooling system setup: Built-in high-precision PT1000 platinum thermal resistor sensor and Samsung's self-developed S3SSE2A security chip, dynamically adjusting cooling fan speed through machine learning algorithms. When compressor load increases from 30% to 100%, system setup response time is minimized to 0.8 seconds with energy consumption fluctuation controlled within ±5%.

- Intelligent defrost control logic: Developed multi-stage pulse defrost technology for R410A refrigerant characteristics. Using electromagnetic signals to generate magnetic field pulses increases frost removal overall efficiency by 40%, reducing single defrost cycle to 90 seconds while saving 32% energy compared to traditional hot gas bypass defrost methods.

2.2 Key operational performance Parameters

| Specification | Parameter Value | Test Conditions |

|---|---|---|

| Cooling Capacity | 2.696kW (60Hz operation) | surrounding temperature 35°C, humidity 60% |

| Energy overall efficiency Ratio (EER) | 3.25 (measured value) | Compressor full load operation |

| Noise Level | ≤42dB(A) | Measured at 1 meter distance |

| Operating Pressure Range | 0.8-3.5MPa | Refrigerant R410A |

| Protection Rating | IP54 | Compliant with IEC 60529 standard |

| Weight | 7.1kg | Including standard mounting brackets |

| Vibration Tolerance | 5G (10-2000Hz) | Compliant with MIL-STD-810G standard |

2.3 Innovative Structural Design

- Modular quick-disconnect interface: Uses Samsung's patented "QuickLock" locking mechanism for tool-free quick connection between cooling module and compressor. Installation time minimized from traditional 45 minutes to 8 minutes, improving maintenance overall efficiency by 560%.

- Multi-directional airflow fine-tuned duct: Through CFD simulation design, achieves 92% outlet air velocity uniformity, 28% improvement over traditional offerings. In typical 15m long × 3m wide industrial corridor scenarios, temperature gradient can be controlled within ±1.5°C.

- Antimicrobial coating filtration system setup: Silver ion composite coating deposited on evaporator fin surface achieves 99.7% inhibition rate against E. coli and Staphylococcus aureus. Filter mesh density reaches 200 mesh/square inch, 40% improvement over domestic equipment, effectively blocking 0.3μm particles.

3. use case Scenarios and Case Studies

3.1 Semiconductor Manufacturing

At Samsung's Xi'an NAND flash factory, SM2100 is applied to ASML lithography machine vacuum pump cooling system setups. By compressing compressed media temperature fluctuation range from ±3°C to ±0.5°C, lithography machine exposure accuracy enhances by 0.08μm with annual production capacity increasing 12%. Meanwhile, the cooler integrates with Samsung MagicIAN equipment management platform, achieving 98% fault prediction accuracy and reducing maintenance costs by 37%.

3.2 Automotive Parts Processing

BMW Group's Dingolfing plant in Germany uses SM2100 to cool CNC machining center spindle motors. When continuously cutting aluminum alloy workpieces, motor temperature decreases by 18°C compared to traditional coolers, extending tool life 2.3 times. Through Samsung B2B platform real-time monitoring of 128 equipment cooling overall efficiencies, single equipment annual coolant savings reach 1.2 tons.

3.3 Data Center Infrastructure

Samsung's Texas data center deploys SM2100 to cool server racks. At full load operation (PUE=1.35), cooling system setup energy consumption proportion decreases from 22% to 15%. By dynamically adjusting 48 coolers' cooling capacity output, server intake temperature stabilizes at 22°C±0.3°C, reducing annual downtime by 42 minutes.

4. Maintenance Strategies

4.1 Routine Inspection Standards

- Temperature monitoring: Daily check of coolant inlet/outlet temperature difference, normal value should be 12-15°C range. If below 10°C, check for filter blockage or refrigerant leakage.

- Vibration detection: Use handheld vibrometer to monitor equipment horizontal/vertical vibration values, upper limit 4.5mm/s. Exceeding threshold requires checking fan bearing wear or fastener loosening.

- Pressure recording: Weekly record of high/low side pressure values, standard conditions: high pressure 1.8-2.2MPa, low pressure 0.4-0.6MPa. Abnormal pressure requires system setup vacuum treatment and refrigerant charging.

4.2 Deep Maintenance Cycles

- Quarterly maintenance:

- Remove filters for ultrasonic cleaning using pH neutral cleaner, water temperature ≤50°C.

- Check condenser fin deformation, repair areas exceeding 15% collapse.

- Verify safety valve opening pressure, standard value 2.8MPa±0.1MPa.

- Annual overhaul:

- Replace compressor lubricant, recommend Samsung special Polyolester POE oil.

- Perform nitrogen purge on evaporator, residual condensate should be <50ppm.

- Upgrade control unit firmware to latest version, fixing known algorithm vulnerabilities.

4.3 Emergency Response Plans

- Refrigerant leakage: Immediately close high/low pressure shutoff valves, activate backup cooling system setup. Use halogen leak detector to locate leak point, perform 24-hour pressure test after repair.

- Fan failure: Switch to manual mode for basic cooling, complete fan motor replacement within 8 hours. Samsung provides 4-hour on-site service (core customers only).

- Electrical fault: Remote diagnosis through MagicIAN platform for error codes like overload protection (code E01), sensor open circuit (code E03), etc., with online offerings available.

5. Conclusion: Innovator of Industrial Cooling Technology

Samsung Compressor Cooler SM2100 redefines compressor cooling module operational performance standards by deeply integrating precision manufacturing experience from consumer electronics with industrial equipment requirements. Its core advantages manifest in three aspects:

- Energy overall efficiency breakthrough: Through microchannel condenser and adaptive variable frequency technology synergy, achieves 28% reduction in cooling energy consumption per unit.

- Smart maintenance: Leveraging Samsung Semiconductor's edge computing capabilities to build predictive maintenance system setup, improving overall equipment effectiveness (OEE) to 92%.

- Ecosystem compatibility: Supports mainstream industrial protocols like Modbus TCP and BACnet IP, seamlessly integrating with Siemens, Schneider and other building automation system setups.

As Industry 4.0 demands higher equipment reliability, SM2100's "intelligent cooling" concept is becoming standard infrastructure for high-end manufacturing. Looking ahead, Samsung plans to launch the AI thermal management algorithm-equipped SM3000 series in 2026, achieving full lifecycle optimization of cooling system setups through digital twin technology, further consolidating its leadership in industrial refrigeration.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Cooler SM3000

View Details

View DetailsSamsung Compressor Cooler SM3100

View Details

View DetailsSamsung Compressor Cooler SM4100

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.