Samsung Compressor AfterCooler

Comprehensive technical specifications and industrial application solutions for Samsung's advanced compressed air cooling systems

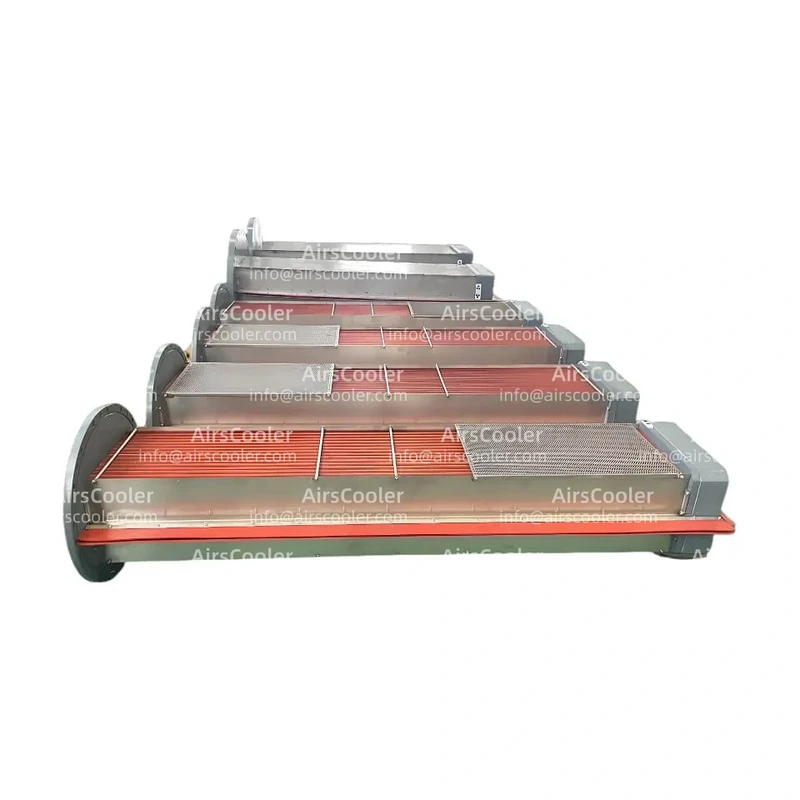

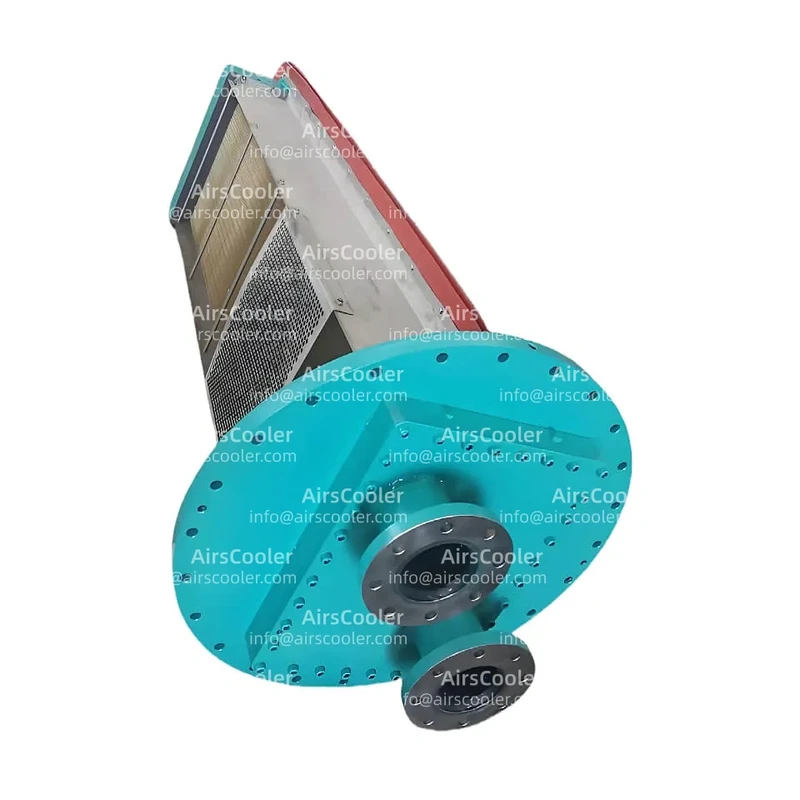

1. Product Overview: Core module of Industrial Compressed Air system setups

The Samsung Compressor AfterCooler (referred to as "AfterCooler") is a heat exchange device specifically built for industrial-grade compressed air system setups. Its primary function is to cool high-temperature, high-pressure gas discharged from air compressors (reaching up to 180°C) to below 40°C through thermodynamic principles.

Technical Positioning and Industry Value

As a critical module in post-processing system setups for air compressors, the AfterCooler directly relates to compressed air quality standards (ISO 8573-1). For example, technical parameters of a Samsung model show: at an intake temperature of 80°C and pressure of 0.8MPa, it can minimize condensate content in compressed air from 18g/m³ to below 2.5g/m³, with pressure dew point consistently keep between 2-10°C.

Structural Innovations and Material Breakthroughs

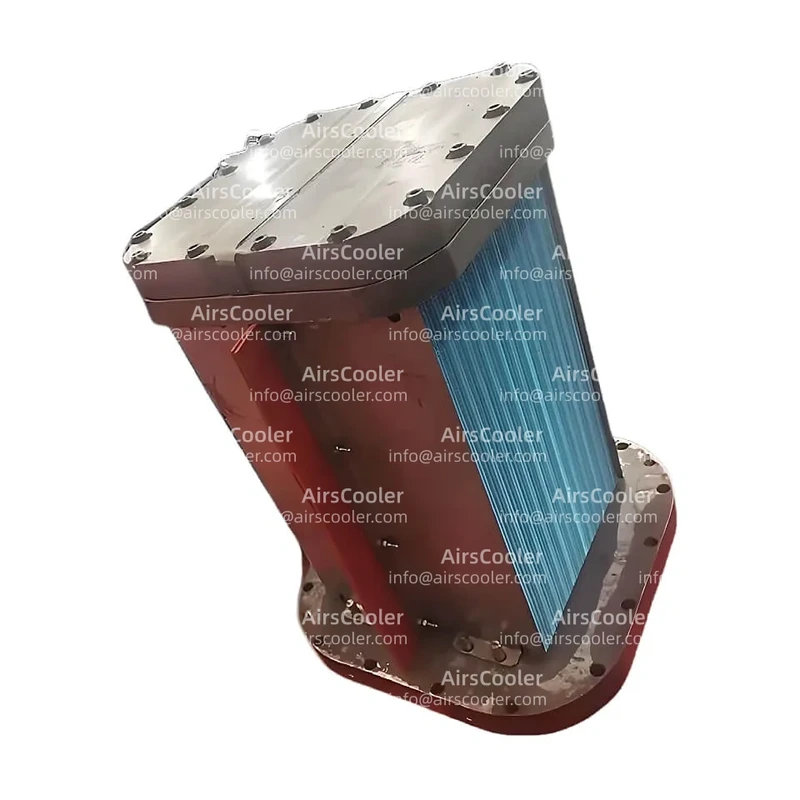

The series features a double-tube vertical structure with core heat exchange elements made of φ14×1mm copper tubes (thermal conductivity of 380W/(m²·℃)), representing a 744% improvement over traditional steel pipes.

| operational performance Metric | Standard Design | Samsung AfterCooler | Improvement |

|---|---|---|---|

| Heat Transfer Area | 100% | 60% | 40% reduction |

| Equipment Volume | 100% | 80% | 20% reduction |

| Cost Increase | 0% | 3.8% | Minimal impact |

2. Technical Features and Data Specifications

1. Heat Transfer overall efficiency Optimization system setup

Fluid Dynamics Optimization: Airside velocity designed at 12-15m/s, 40% higher than conventional products, combined with axial vortex generators on corrugated tube surfaces minimizes boundary layer thickness below 0.3mm.

2. Durability and Reliability Design

Tube-Shell Connection Technology: Uses TIG welding + expansion joint composite process with weld strength reaching over 95% of base material, passing 100,000 pressure cycle tests without leakage.

3. Environmental and Energy overall efficiency Indicators

Water Conservation: Water-cooled models use only 65% of traditional design's cooling water circulation, saving up to 1,200 tons annually per unit at 32°C inlet temperature.

3. use case Scenarios and Case Studies

1. Semiconductor Manufacturing

In a Samsung 12-inch wafer fab project, AfterCooler combined with adsorption dryers keep compressed air dew point at -70°C, meeting Class 1 cleanroom standards.

2. Pharmaceutical Production

A biopharmaceutical company using this series achieved 99.99995% microbial retention overall efficiency (validated by VHP sterilization) with maintenance downtime under 2 hours/year.

4. Maintenance Strategies

1. Preventive Maintenance system setup

Smart Monitoring: Integrated vibration sensors and infrared thermal imaging modules provide 30-day advance warning of heat exchange tube scaling risks.

2. Fault Diagnosis and Repair

Abnormal Pressure Loss: When ΔP > 0.05MPa, check baffle spacing blockages and nano-coating integrity.

5. Technology Evolution and Industry Trends

1. New Material use cases

Samsung is developing silicon carbide-based composite heat exchange tubes with thermal conductivity up to 800W/(m²·℃), featuring self-healing coating technology for commercial release by 2026.

2. Process Innovation Directions

3D Printed thermal exchangers: Topology-fine-tuned designs achieve 30% lower flow resistance and 50% greater heat transfer area.

3. Industry Standard Developments

Updated ISO 12500 series now requires: Class A energy overall efficiency (COP > 0.85), OPC UA protocol support for control system setups, and ISO 13374 compliant maintenance interfaces.

Conclusion

Samsung Compressor AfterCooler redefines operational performance boundaries for industrial compressed air cooling system setups through integrated advancements in materials science, fluid dynamics, and intelligent control. From semiconductor cleanrooms to Middle Eastern oil fields, its proven stability in extreme conditions and lifecycle cost optimization make it the preferred offering for global advanced manufacturing.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung TM900 Intercooler

View Details

View DetailsSamsung Compressor Cooler SM2100

View Details

View DetailsSamsung Compressor Cooler SM3000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.