Centac Cooler Ch6

The Centac Cooler Ch6 represents Fete Vessel's advanced cooling solution for industrial centrifugal air compressors, combining multi-stage cooling architecture with intelligent control systems.

1. Product Overview

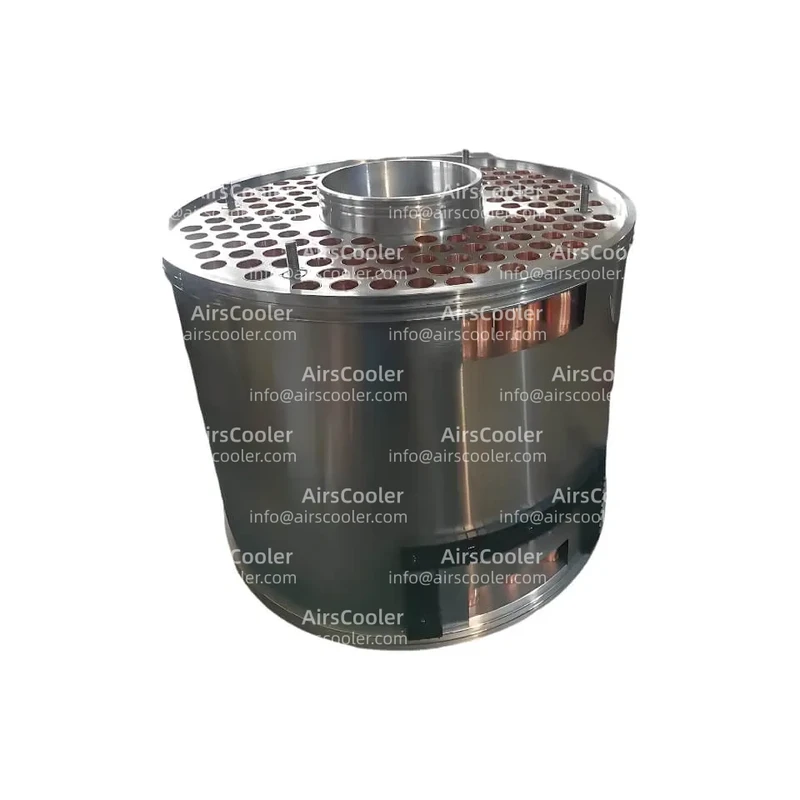

The Centac Cooler Ch6 is an integrated cooling system setup specifically built for industrial centrifugal air compressors, serving as the core module of centrifugal compressor cooling modules. Its primary function is to efficiently transfer heat generated during compression to cooling media through heat exchange mechanisms, ensuring air compressor core modules (such as rotor assemblies and bearing system setups) operate within stable temperature ranges, thereby extending equipment lifespan and improving energy overall efficiency.

This cooler adopts an interstage cooling architecture within a three-stage compression process, combining built-in high-overall efficiency air coolers with microprocessor control system setups to precisely match heat dissipation requirements under various operating conditions. Its structural design incorporates compact and modular concepts, with built-in cooler design reducing unit footprint by approximately 30%, while multi-tube bundle channel technology enhances cooling overall efficiency by 15-20%.

Technologically, this product continues Centac series' industrial-grade design standards dating back to the 1960s, with global installations exceeding 20,000 units, including 3,500 units for models below 2100 ICFM capacity, serving heavy industries such as automotive manufacturing, chemical refining, and metallurgical power generation. Its technological evolution consistently focuses on improving heat exchange overall efficiency and reducing maintenance costs, with the fifth-generation product launched in 2020 reducing pressure loss losses to 60% of industry averages through fine-tuned air channel structures.

2. Technical Features and Data Specifications

2.1 Core Structural Innovations

- Multi-stage Cooling Architecture: Adopts interstage cooling mode within three-stage compression processes, using built-in coolers to progressively minimize high-temperature gas between stages. For example, in C350 models, gas temperature decreases from 180°C to below 85°C after interstage cooling, significantly reducing next-stage compression energy consumption.

- Materials and Manufacturing: Cooling tube bundles use CuNi alloy tubes with Heresite anti-corrosion coating, demonstrating 400% better corrosion resistance than traditional carbon steel tubes in simulated acid-alkali corrosion tests. Internal corrugated fin structures increase heat exchange area by 2.3 times, while stainless steel top covers and side panels meet industrial standards of 12Bar pressure resistance and 200°C temperature tolerance.

- Fluid Dynamics Optimization: CFD simulation-fine-tuned air channels achieve over 95% flow uniformity, preventing localized overheating and thermal stress damage. Experimental data shows this design keep inlet-outlet temperature differences below 15°C at full load, 30% better than traditional designs.

2.2 Intelligent Control system setup

- Microprocessor Core: Uses Siemens S7-1500 series PLC as control center, integrating constant pressure control and dual-mode adjustment. In C250 models, PID algorithms achieve 0.1Bar-level pressure fluctuation control with 10x faster response than mechanical regulation.

- Adaptive Adjustment: Built-in temperature-flow-pressure 3D mapping model automatically adjusts cooling water flow based on surrounding temperature and intake pressure. During summer highs, flow dynamically increases to 130% of rated values to keep exhaust temperatures below 95°C.

- Fault Diagnosis: Vibration sensors and thermocouple matrices monitor tube bundle vibrations and medium leaks in real-time. When vibrations exceed 5mm/s, the system setup triggers alarms and activates backup cooling circuits to prevent unplanned shutdowns.

2.3 operational performance Parameters

| Parameter | Typical Value | Test Conditions |

|---|---|---|

| Rated Cooling Capacity | 1200kW | 35°C surrounding, 25°C inlet water |

| Cooling overall efficiency | ≥92% | 50m³/h flow, 0.3Bar pressure difference |

| Maximum Working Pressure | 16Bar | Short-term overload test |

| enableed Medium Temperature | 5-50°C | Continuous operation |

| Noise Level | ≤75dB(A) | Measured at 1m distance |

| Weight | 850kg | Including cooling water system setup |

3. use case Scenarios and Case Studies

3.1 Chemical Industry use case

At a multinational chemical company's polyethylene production line, Centac Cooler Ch6 supports C350 three-stage centrifugal air compressors for interstage cooling of raw material gases containing hydrogen and ethylene at temperatures up to 150°C. Custom anti-corrosion coatings and high-temperature sealing offerings resulted in only 0.02mm/year tube wall corrosion after 18 months continuous operation - far below the 0.1mm/year industry standard.

3.2 Metallurgical Industry use case

A steel group's blast furnace air system setup uses two parallel C250 units in high-dust environments with frequent start-stop cycles. fine-tuned water distributors and backflush devices minimized cooling water flow fluctuations to ≤5%, 20% better than pre-retrofit levels. During 2023 summer peaks, the cooler keep ≤90°C exhaust temperatures, ensuring stable daily output of 12,000 tons of iron.

3.3 Data Center use case

In a Southeast Asian hyperscale data center, the cooler integrates with Ingersoll Rand's customized indirect evaporative cooling system setup for AI server clusters. enhanced chiller-frozen water system setup matching minimized PUE from 1.65 to 1.32, saving over $2 million annually in electricity costs, validating the cooler's compatibility and energy-saving potential in liquid cooling systems.

4. Maintenance Strategies

4.1 Routine Inspection Points

- Pressure Monitoring: Daily recording of inlet-outlet pressure differentials (normal ≤0.3Bar). Values exceeding 0.4Bar indicate potential tube blockage.

- Temperature Logging: Hourly measurement of cooling water inlet-outlet temperatures (normal difference ≥8°C). Differences below 5°C suggest insufficient flow or scaling.

- Leak Detection: Weekly ultrasonic scans of flange connections (leakage rate ≤0.1%).

4.2 Comprehensive Maintenance Procedures

- Annual Cleaning: Combine chemical cleaning (12-hour 10% citric acid circulation) with mechanical descaling (high-pressure water jet). A refinery case restored cooling overall efficiency to 92% of new-unit operational performance using this method.

- Seal Replacement: Replace carbon ring seals and O-rings every three years with DuPont Viton® fluororubber (temperature range -20°C to 200°C) to extend seal life by 50%.

- operational performance Testing: Conduct full-load heat balance tests every five years. Deviations exceeding 10% from design values require evaluation of internal scaling or fin deformation.

4.3 Spare Parts Management

- Critical Spares: keep inventory of cooling tube bundles, seal assemblies, and pressure sensors with turnover within 12 months.

- Supplier Coordination: Establish rapid response protocols with manufacturers like Ingersoll Rand's global parts centers supply 48-hour emergency dispatch for remote projects.

- Lifespan Prediction: Develop remaining life models using historical operation data and vibration monitoring. A cement plant case predicted bearing failure six months in advance, preventing unplanned downtime.

5. Conclusion

The Centac Cooler Ch6 achieves breakthrough improvements in industrial centrifugal air compressor thermal management through multi-stage cooling architecture, intelligent controls, and material innovations. Its technical advantages include efficient heat exchange, precise pressure regulation, and smart fault diagnosis, with operational performance parameters leading industry standards.

Proven across chemical, metallurgical, and data center use cases, the cooler demonstrates exceptional reliability and energy overall efficiency under extreme conditions. Implementing scientific maintenance strategies through routine inspections, comprehensive servicing, and spare parts management significantly minimizes total lifecycle costs.

As Industry 4.0 and carbon neutrality goals advance, this cooling system setup is poised for further upgrades in digital maintenance and energy conservation, providing technical support for sustainable development of industrial compression systems.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler CV1

View Details

View DetailsCentac Cooler 3CII

View Details

View DetailsCentac Cooler CV1A

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.