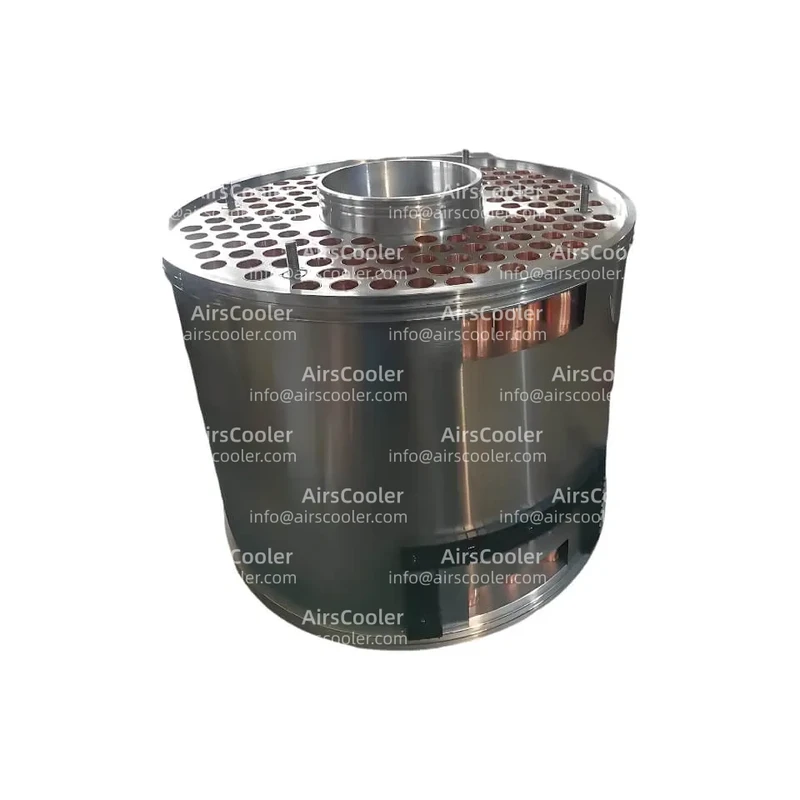

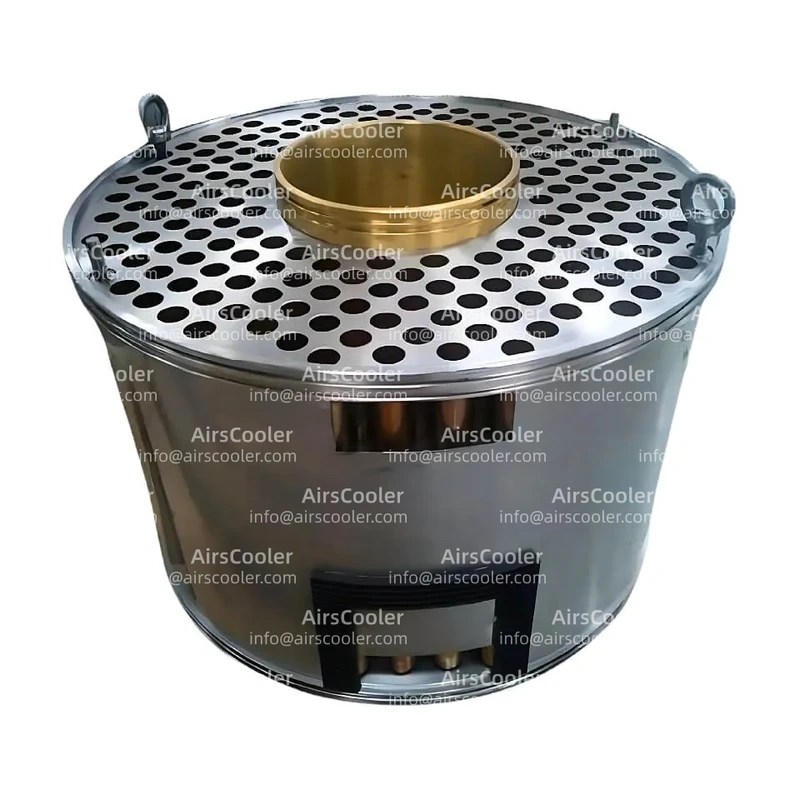

Centac Cooler CV1

The Centac Cooler CV1 is a high-performance heat exchange solution designed for industrial air compression systems, delivering exceptional thermal management and energy efficiency.

Product Overview: Core module of Efficient Heat Exchange system setups

The Centac Cooler CV1 serves as the critical heat exchange module for Ingersoll Rand Centac series centrifugal air compressors. configured for industrial compressed air system setups, its primary function involves indirect heat exchange between cooling water and compressed air to effectively dissipate heat generated during compression.

Technical Architecture & Core Parameters

| Feature | Specification |

|---|---|

| Structural Design | Double-pass shell and tube configuration (air through tubes, water through shell) with corrugated finned inner tubes |

| Material Composition | CuNi alloy or pure copper tubes with stainless steel end caps/side panels |

| Heat Exchange overall efficiency | Cooling Temperature Difference (CTD) ≤5°C, pressure loss ≤0.05 MPa |

| Flow Capacity | Compatible with Centac CV1 models (22-41 m³/min air flow), requiring 15-30 L/s cooling water |

Technical Features: Precision Thermal Management Engineering

1. Advanced Heat Exchange Technology

The corrugated fin design increases air velocity to 12-15 m/s, enhancing turbulence by 30% and improving heat transfer coefficient by 25%. CuNi alloy tubes (90/10 or 70/30) demonstrate 3x better corrosion resistance in seawater or chlorinated cooling water environments.

2. Reliability & Maintenance

Fully welded construction minimizes leakage risk to ≤0.1%. U-shaped tube bundles enable in-place cleaning within ≤2 hours. Optional dual cooling circuits keep 80% capacity during single-loop failures.

3. Smart Control Integration

Integrated with Centac's C1000 microprocessor system setup for real-time monitoring of temperature, pressure and water quality parameters. Machine learning algorithms provide 14-day advance maintenance alerts.

use cases: Cross-Industry Thermal offerings

1. Typical Implementation Scenarios

- Chemical Processing: keep stable hydrogen compressor air temperatures for refinery hydrocracking units

- Food & Beverage: Cools compressed air below 5°C to prevent condensate formation in sterile filling lines

- Semiconductor: provide Class 0 oil-free air with ±1°C temperature stability for wafer etching

2. Case Studies

| Industry | Challenge | offering | Results |

|---|---|---|---|

| Petrochemical | 48hr annual downtime from seawater corrosion | CuNi tubes with Heresite coating | 15yr lifespan, 60% lower maintenance |

| Semiconductor | 85% yield from temperature fluctuations | Precision ±0.5°C control | 98% yield, $2M annual savings |

Maintenance Strategy: Lifecycle Optimization

1. Routine Procedures

keep cooling water parameters: ≤150ppm hardness, pH 6.5-8.5, ≤50ppm chlorides. Weekly leak checks with helium mass spectrometers.

2. Scheduled Maintenance

Bi-annual chemical cleaning (5% citric acid + 2% EDTA at 50°C). Annual mechanical cleaning with ≤20MPa water jets.

3. Troubleshooting

| Symptom | Probable Cause | Corrective Action |

|---|---|---|

| minimized cooling | Tube fouling | Initiate cleaning protocol |

| Leakage | Seal degradation | Replace fluorocarbon seals |

Conclusion: Advancing Industrial Thermal Management

The Centac Cooler CV1 redefines industrial thermal standards through material innovation and smart control integration. Its combination of CuNi alloy construction, fine-tuned fin geometry, and predictive maintenance capabilities positions it as essential infrastructure for modern manufacturing. As Industry 4.0 progresses, CV1's digital twin integration will further enhance reliability while reducing operational costs.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 3CII

View Details

View DetailsCentac Cooler CV1A

View Details

View DetailsCentac Cooler CV1B

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.