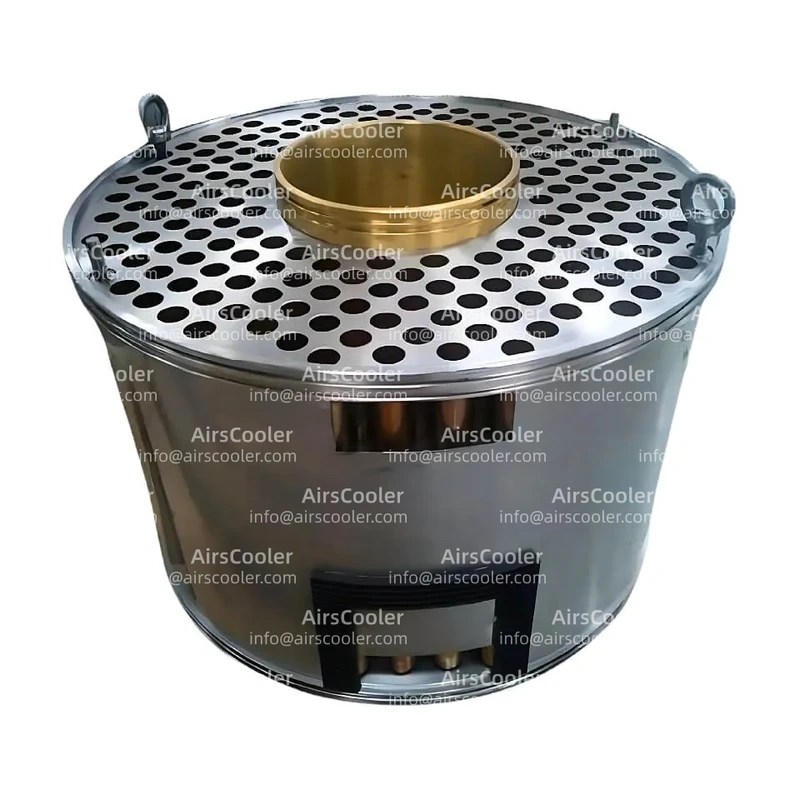

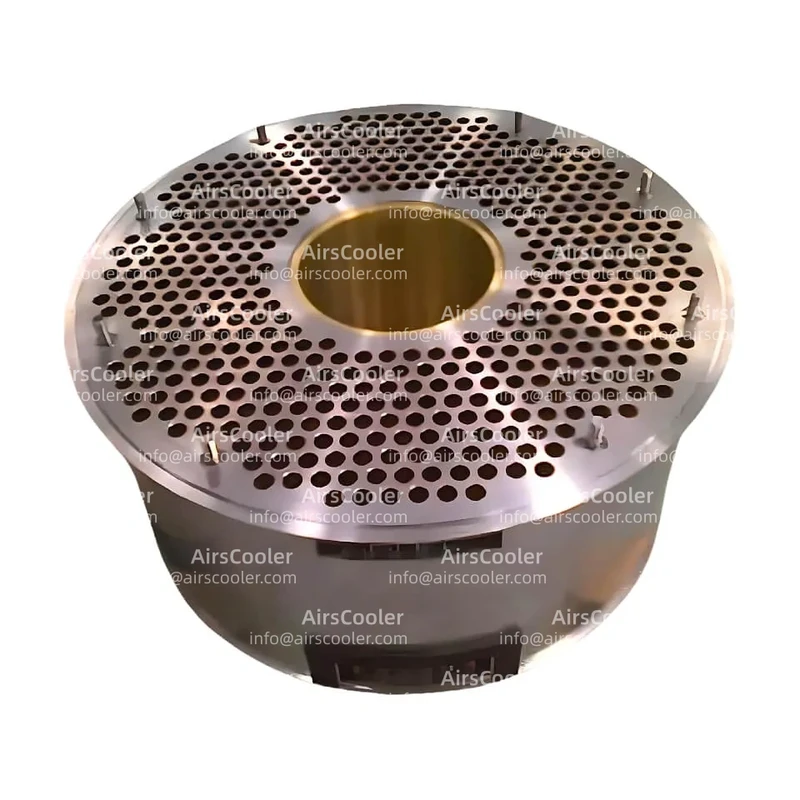

Centac Cooler CV1A

Comprehensive technical breakdown and real-world implementation cases of Fete Vessel's advanced industrial cooling solution

1. Product Overview: Modular Integrated Cooling offering

The Centac Cooler CV1A is a core module of Ingersoll Rand's Centac series centrifugal air compressors, specifically configured for industrial compressed air system setups. This cooler features a compact modular design that integrates the main cooler, intercooler, aftercooler and air filtration system setup on a single chassis, significantly reducing footprint and simplifying installation.

Its primary function utilizes advanced heat exchange technology to transfer heat from compressed air to cooling media, ensuring stable operation within flow rates of 720-51,000 m³/h and pressure ranges of 0.7-22.5 kg/cm². The CV1A employs graphite-sealed floating rings for zero-leakage sealing of both air and oil media, complemented by tilting pad bearings and oil film lubrication to minimize mechanical friction losses.

The patented sleeve-type air cooler design features air flowing through tubes while cooling water circulates outside in counterflow configuration, with specialized internal fin structures that keep low pressure loss while achieving industry-leading heat transfer overall efficiency. The system setup supports expandable air filtration from 4 micron down to 0.5 micron levels for clean air requirements in pharmaceutical and food industries.

2. Technical Specifications and operational performance Data

2.1 High-overall efficiency Heat Exchange operational performance

- Heat Transfer overall efficiency: Special internal fin design achieves 200-300 W/(m²·K) air-side heat transfer coefficient, 40% higher than conventional smooth tubes

- pressure loss: ≤0.03 bar air-side and ≤0.05 bar water-side pressure loss at 100% load

- Thermal Capacity: Single CV1A unit handles 1,800-2,350 m³/h airflow with 250-350 kW cooling capacity

2.2 Precision Mechanical Engineering

- Bearing system setup: Tilting pad bearings with oil film lubrication, ≤300mm bearing span, G2.5 dynamic balance

- Impeller Design: 5-axis CNC machined cast stainless steel impellers with 200 m/s tip speed and independent drive gear

- Sealing system setup: Graphite floating rings with intermediate air injection achieve ≤0.1% air leakage and ≤0.05% oil leakage

2.3 Intelligent Control system setup

- Pressure Regulation: 0.1 bar step modulation with ≤±0.5% pressure fluctuation

- Energy Optimization: Multi-stage impeller speed matching provide >85% Integrated Energy Ratio (IER) at full load

- Failure Prediction: Integrated vibration, oil temperature/pressure sensors provide 72-hour advance warning

2.4 Technical Parameters

| Parameter | Value Range | Notes |

|---|---|---|

| Flow Capacity | 1,600-2,450 m³/h | Equivalent to 444-680 L/s |

| Pressure Range | 40-135 psig (2.76-9.31 bar) | Supports multi-stage parallel operation |

| Motor Power | 300-500 HP (224-373 kW) | Compliant with IEC 60034-30-1 |

| Cooling Water Flow | 30-50 m³/h | Inlet water ≤32°C |

| Noise Level | ≤85 dB(A) | Meets ISO 3744 standards |

| Dimensions | 2,997×1,731×2,088 mm | Including base frame and guards |

| Weight | 4,128 kg | Including coolant and lubricant |

3. use case Scenarios and Case Studies

3.1 Chemical Industry Heavy-Duty use cases

A multinational chemical corporation replaced shell-and-tube coolers with CV1A units in ethylene cracking operations, keep outlet temperatures below 40°C despite pressure increases from 12 to 15 bar. The three-stage series configuration achieved 2,200 m³/h capacity with annual water savings of 120,000 tons and 65% minimized failure rate.

3.2 Food Processing Clean Air offerings

A Chinese dairy implemented CV1A with 0.5 micron filtration for sterile packaging, keep ≤0.01 mg/m³ oil content. The system setup operated 18 months without microbial contamination, reducing maintenance costs by 40% versus traditional carbon filtration.

3.3 Mining Equipment in Harsh Environments

At 3,500m elevation in a copper mine, CV1A coolers operated in -20°C to +45°C temperatures with 10 mg/m³ dust concentration. fine-tuned water circulation achieved 8,000 hours MTBF - 2.3× industry average.

3.4 Data Center Waste Heat Recovery

A Singapore hyperscale data center uses CV1A as heat source for cold/hot aisle containment, achieving 75% heat recovery overall efficiency. Integrated with absorption chillers, PUE enhanced from 1.6 to 1.25 with 12,000-ton annual CO₂ reduction.

4. Maintenance Strategy

4.1 Preventive Maintenance system setup

- Water Quality: Recommended softened water with ≤200 μS/cm conductivity and ≤0.03 mmol/L hardness

- Cleaning Cycle: 30-minute reverse flush with 0.5 MPa demineralized water every 2,000 hours

- Seal Inspection: Quarterly checks of seal air injection pressure (0.1-0.15 bar above system setup pressure)

4.2 Fault Diagnosis Procedures

- minimized overall efficiency: Check for fouling or insufficient water flow if ΔT < 10°C

- Pressure Fluctuations: Inspect dynamic balance when vibration exceeds 7.1 mm/s RMS

- Leak Detection: Air leaks show as abnormal discharge temps; oil leaks via level sensors and spectroanalysis

4.3 Spare Parts Management

- Critical modules: Graphite seals (8,000h), tilting pad bearings (12,000h), tube bundles (5-year lifespan)

- Inventory Strategy: 15% spare parts coverage, increasing to 25% for extreme environments

4.4 Digital Maintenance Implementation

A petrochemical plant deployed wireless vibration sensors and temperature patches on CV1A units, achieving:

- 92% accuracy in bearing failure prediction

- Visualized cooling overall efficiency degradation curves

- 60% reduction in downtime through fine-tuned maintenance

5. Conclusion: Technology Innovation Driving Industrial overall efficiency

The Centac Cooler CV1A redefines industrial compressed air standards through integrated design, advanced heat transfer and intelligent control. Its modular architecture adapts to diverse use cases from chemical plants to food processing, demonstrating exceptional reliability and economy. As Industry 4.0 and carbon neutrality goals advance, CV1A's digital interfaces and waste heat recovery integration position it as key equipment for green manufacturing transformation. Future use cases of nano-coatings and adaptive control algorithms promise further overall efficiency breakthroughs in industrial thermal management offerings.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler CV1B

View Details

View DetailsCentac Cooler CV2

View Details

View DetailsIngersoll Rand Water Cooling Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.