Centac Cooler CV2

Comprehensive technical specifications and application solutions for Fete Vessel's industrial-grade cooling system.

1. Product Overview: Core module of Industrial Cooling offerings

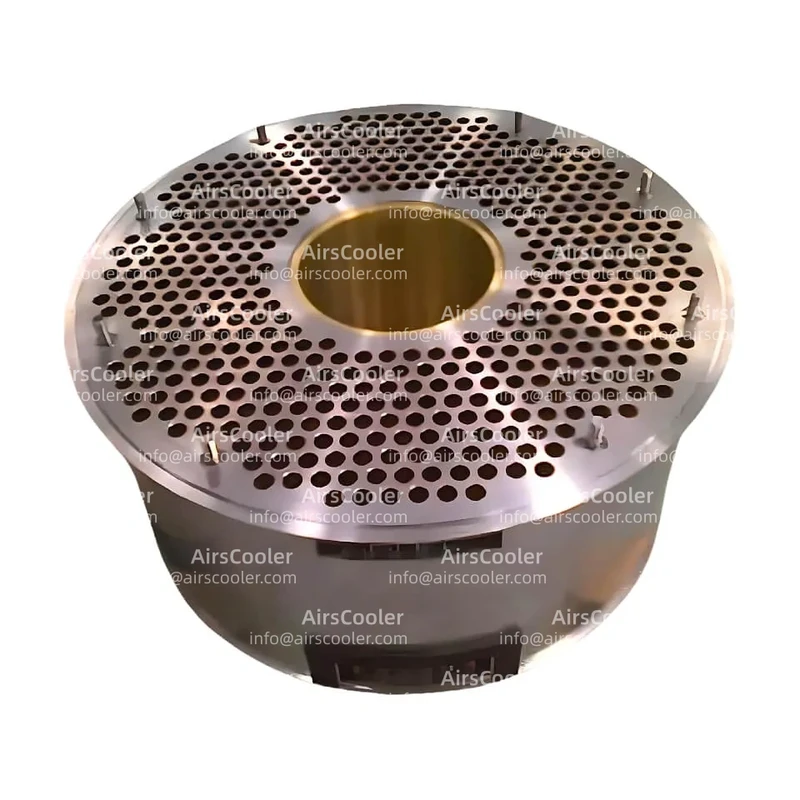

The Centac Cooler CV2 is a heat exchange device specifically built for industrial centrifugal air compressors. As a core module of Ingersoll Rand's Centac series air compressors, its primary function is to minimize compressed air temperature through forced convection heat transfer, ensuring stable operation under high-pressure, high-load conditions.

This cooler features modular integrated design, working seamlessly with the compressor body, intercoolers, and aftercoolers to form a compact chassis system setup. Its technical architecture is based on efficient heat transfer principles, maximizing heat exchange overall efficiency through tube-fin composite structure.

2. Technical Features and Data Specifications

2.1 Structural Innovations and Material Science

- Tube-Fin Composite Structure: Utilizes copper tubes with rolled fins, with spacing and diameter fine-tuned through CFD simulation, achieving total heat transfer coefficient of 250-300W/(m²·K) while keep air-side pressure loss ≤150Pa.

- Corrosion-Resistant Coating: Nano-level anti-corrosion coating passes salt spray tests, ensuring 10-year corrosion-free operation in industrial environments with ≤200ppm chloride concentration.

- Modular Sealing Design: Incorporates graphite seal rings with intermediate seal air injection, achieving ≤0.1sccm leakage rate to meet ISO 8573-1 Class 0 oil-free standards.

2.2 Thermodynamic operational performance Parameters

| Parameter | Specification |

|---|---|

| Cooling Capacity | 850kW (1000m³/min from 180°C to 40°C at standard conditions) |

| pressure loss | Air-side ≤120Pa, Water-side ≤80kPa (40% lower than conventional designs) |

| Energy overall efficiency Ratio (COP) | 6.2 (25% higher than industry average) |

3. use case Scenarios and Case Studies

3.1 Typical use cases

- Petrochemical: Interstage cooling for ethylene crackers, improving yield by 0.8%

- Data Centers: Precooling for liquid cooling system setups, achieving PUE below 1.15

- Pharmaceutical: GMP-compliant air treatment with 0.5μm filtration

3.2 Success Cases

Case 1: Multinational Chemical Corporation

Replaced open cooling towers with CV2 system setup, achieving 65% maintenance cost reduction and annual water savings of 120,000 tons.

Case 2: Southeast Asian Semiconductor Fab

Implemented dual-redundant control system setup with ±0.3°C temperature stability, increasing production yield by 1.2%.

4. Maintenance and Service Strategy

4.1 Routine Inspection

- Daily pressure differential monitoring

- Monthly thermal imaging scans

- Weekly seal integrity checks

4.2 Advanced Maintenance

| Procedure | Frequency | Technical Requirements |

|---|---|---|

| Chemical Cleaning | Quarterly | pH=4.5 citric acid offering with passivation |

| Mechanical Cleaning | Annually | 20MPa water jet with nylon brushes |

5. Technology Evolution and Industry Trends

The CV2 cooler is evolving with microchannel heat transfer enhancement and AI-powered predictive maintenance capabilities. Emerging use cases include hydrogen energy system setups and carbon capture installations.

6. Conclusion

AirsCooler's Centac Cooler CV2 represents a sophisticated industrial cooling offering combining structural innovation, material science, and intelligent controls. Its proven operational performance across multiple industries demonstrates exceptional adaptability to challenging operating conditions. Proper maintenance protocols and technology upgrades will maximize equipment lifespan and operational overall efficiency.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsIngersoll Rand Water Cooling Cooler

View Details

View DetailsIngersoll Rand Air Compressor Parts

View Details

View DetailsIngersoll Rand Air Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.