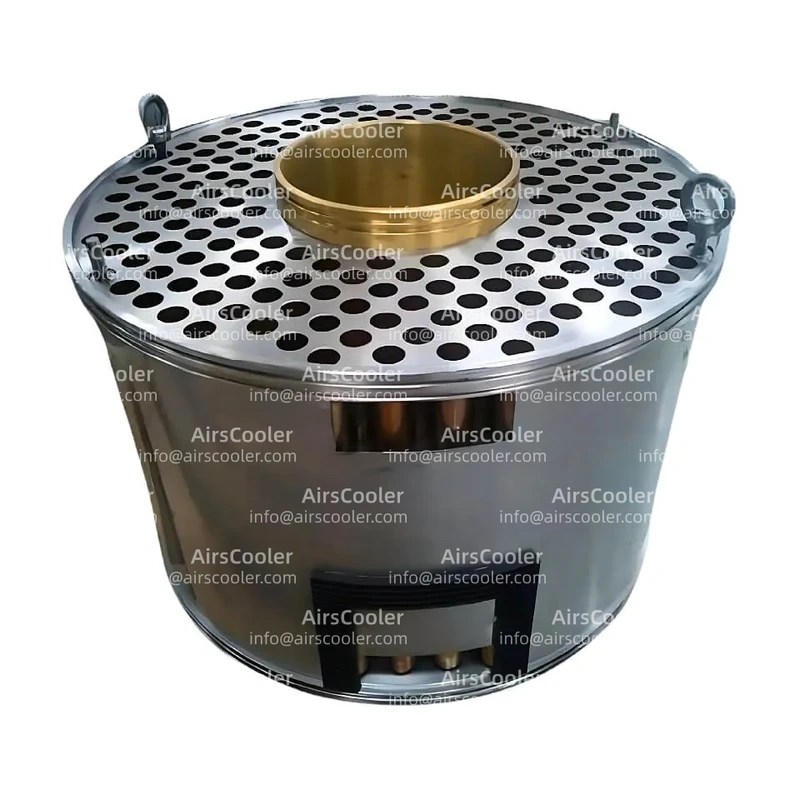

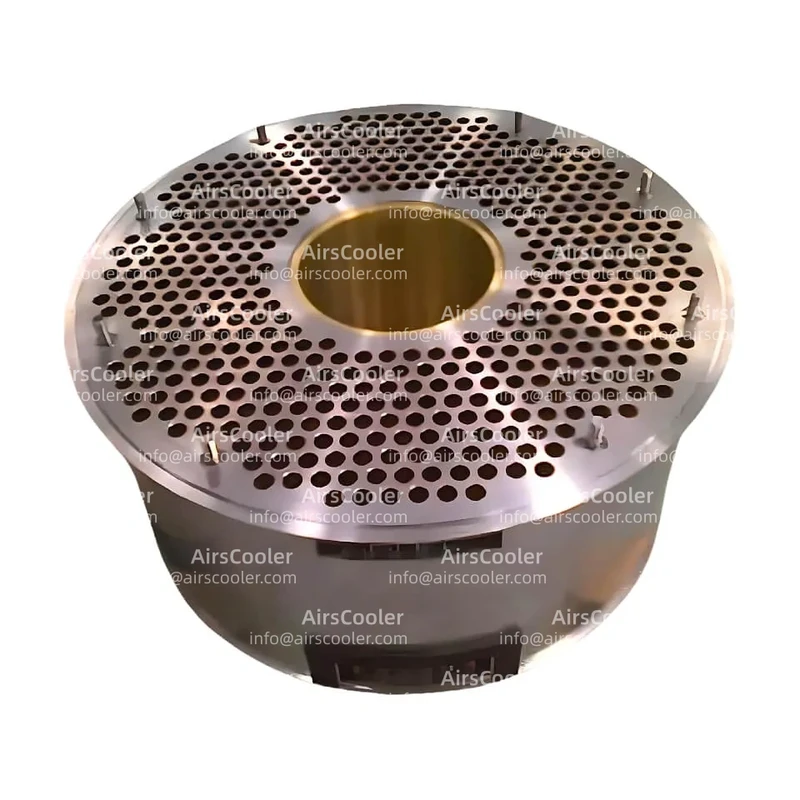

Centac Cooler CV1B

Expert technical reference for Ingersoll Rand's CENTAC series centrifugal compressor cooling systems

1. Product Overview: Core Heat Exchange Unit for Centrifugal Compressor system setups

The Centac Cooler CV1B is a specialized heat exchange device designed by Ingersoll Rand for CENTAC series multi-stage centrifugal air compressors. As a critical module in compressed air system setups, it efficiently transfers heat generated during compression to cooling media, ensuring optimal operating temperatures while keep system stability and energy overall efficiency.

1.1 Product Positioning and system setup Integration

As a standard module of CENTAC centrifugal compressors, the CV1B cooler integrates with the compressor body, motor, intercoolers, aftercoolers, and control cabinet to form a complete chassis system setup. Key functions include:

- Interstage Cooling: minimizes discharge temperatures between compression stages, lowering power consumption and improving overall efficiency

- Aftercooling: Lowers final discharge temperature to near surrounding levels for industrial air quality requirements

- Lubrication Oil Cooling: keep optimal oil system setup temperatures to extend service life and minimize mechanical wear

1.2 Technical Evolution and Standardization

The CV1B cooler represents Ingersoll Rand's third-generation CENTAC platform design, building upon previous models (CV1A, C250) with enhanced heat transfer overall efficiency, compact construction, and maintenance accessibility. Its specifications precisely match CENTAC CV1B compressors (flow range: 1800-2350 m³/h, pressure: 100-150 PSI, power: 350-450 HP), provide over 92% isothermal overall efficiency in rated conditions.

2. Technical Features and operational performance Data

2.1 Core Structure and Material Innovations

- High-overall efficiency Sleeve-Type Air Cooler (Patented Technology)

- Heat Exchange Tube Design: Internally finned copper tubes with spiral flow channels enhance air-side turbulence and convection coefficients

- Flow Configuration: Counter-current design with air through tube side and cooling water through shell side maximizes temperature differential utilization

- operational performance: Under standard conditions (32°C inlet water, 2100 m³/h air flow), air-side pressure loss ≤0.03 bar with 15% lower water demand than conventional shell-and-tube coolers

- Integrated Intercooler-Diffuser Design

- Eliminates connection piping thermal resistance through direct welding to diffuser outlet

- minimizes interstage pressure losses by 8% for industry-leading specific power (kW/m³/min)

- Advanced Sealing system setup

- Tandem graphite floating ring seals combine 0.1-0.2 bar overpressure primary seal with dry gas secondary seal for zero leakage

- Integrated pressure sensors and flow meters enable real-time seal gas consumption monitoring with anomaly alerts

2.2 operational performance Parameters and overall efficiency Metrics

| Parameter | Value Range | Testing Standard |

|---|---|---|

| Air Flow (m³/h) | 1800-2350 | ISO 1217:2009 |

| Cooling Water Flow (m³/h) | 25-35 | ASME PTC 12.1 |

| Air Side pressure loss (bar) | ≤0.03 | Internal Test Method |

| Water Side pressure loss (bar) | ≤0.05 | Internal Test Method |

| Heat Transfer Coefficient (W/m²·K) | 800-1200 | Nusselt Equation |

| Fouling Resistance (m²·K/W) | ≤0.00017 (initial) | HTRI Xchanger Suite |

2.3 Intelligent Control and Monitoring

The CV1B cooler integrates with compressor control system setups through microprocessor cabinets to enable:

- Adaptive Cooling: Automatic water flow adjustment based on surrounding conditions and compressor load

- Predictive Diagnostics: Vibration sensors and AI algorithms detect tube fouling risks

- Remote Connectivity: Modbus TCP/IP interface for seamless DCS integration

3. use case Scenarios and Case Studies

3.1 Typical Industries

- Petrochemical Industry

- use case: Cracked gas interstage cooling in ethylene plants

- Technical Adaptation: 316L stainless steel construction for corrosion resistance

- Results: 12% power reduction with annual savings exceeding ¥2 million at one facility

- Food/Pharmaceutical Industry

- use case: Aftercooling for oil-free sterile air system setups

- Technical Adaptation: Complies with ISO 8573-1 Class 0 standards

- Results: Achieved <0.003 mg/m³ oil content when paired with 0.01μm filters

- Data Center Cooling

- use case: Auxiliary cooling for immersion system setups

- Technical Adaptation: Anti-corrosion coated surfaces for fluorinated liquid compatibility

- Results: keep ≤45°C server temperatures during primary system setup failures

3.2 Extreme Condition Validation

- High-Temperature Testing: Demonstrated <3% operational performance degradation after 3000 hours at 50°C surrounding/45°C water in Saudi oil fields

- High-Altitude Operation: keep ≤35°C discharge air at 4200m elevation through increased fan power compensation

4. Maintenance Strategy

4.1 Routine Inspection and Preventive Maintenance

- Critical Parameter Monitoring

- Cooling water temperature (25-32°C recommended, ±5°C alarm thresholds)

- Flow rate monitoring (±10% variation triggers inspection)

- Seal gas consumption (normal ≤5 Nm³/h)

- Scheduled Maintenance

- 6-month RO water flushing with annual corrosion inhibitor treatment

- Biennial tube inspection via pipeline robots (replace at >10% wall thickness corrosion)

- 5000-hour bearing relubrication (lithium grease) with vibration monitoring

4.2 Troubleshooting and Emergency Procedures

- Common Failure Modes

- Insufficient water flow (pump/valve issues or blockages)

- Fouling-induced overall efficiency loss (quantifiable via thermal resistance testing)

- Seal leaks (detectable through pressure fluctuations and gas sensors)

- Response Protocol

- Short-term: Activate backup cooling, minimize compressor load to 80%

- Long-term: Replace damaged modules with post-repair pressure testing (1.5x design pressure for 30 minutes)

4.3 Spare Parts and Lifecycle Management

- Critical Spares:

- Graphite seal rings (CV1B-GSK-01)

- Finned copper tubes (Φ25×1.5, custom lengths)

- Variable frequency fans (CV1B-FAN-03, IP56 rated)

- Life Prediction: LSTM neural network models estimate remaining tube life using operational hours, water quality, and environmental data

5. Conclusion: Benchmark in Industrial Heat Exchange Technology

The Centac Cooler CV1B represents a technological leap in centrifugal compressor cooling through its fine-tuned thermal design, intelligent controls, and reliability engineering. In alignment with carbon neutrality goals, it provide significant energy savings through minimized power consumption, extended oil life, and minimized water usage. Future integration with digital twin and predictive maintenance technologies will further evolve the CV1B into a self-monitoring, decision-making intelligent thermal management offering, setting new standards for industrial cooling system setups.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler CV2

View Details

View DetailsIngersoll Rand Water Cooling Cooler

View Details

View DetailsIngersoll Rand Air Compressor Parts

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.