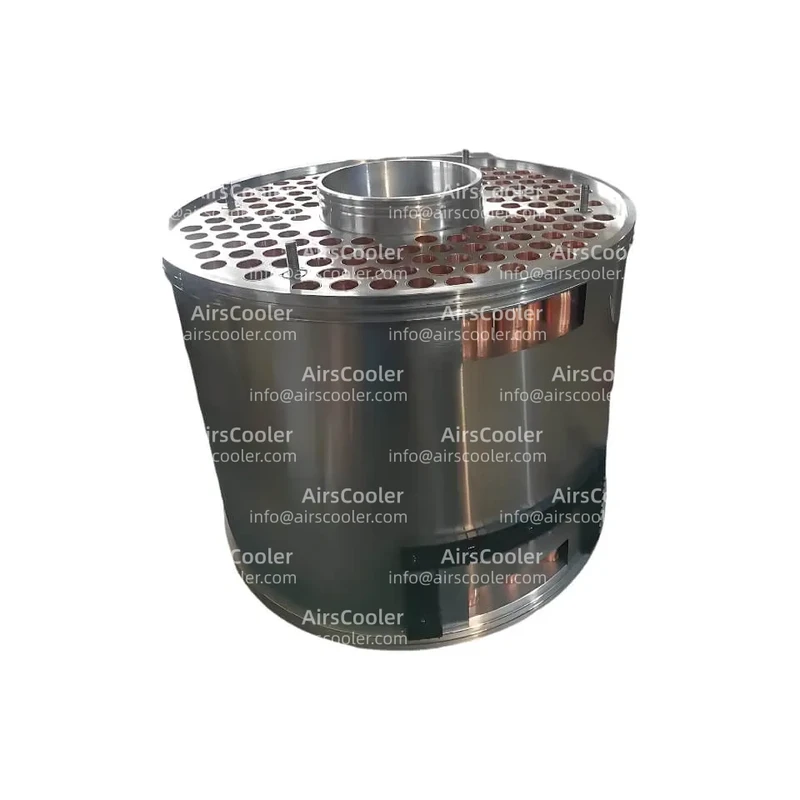

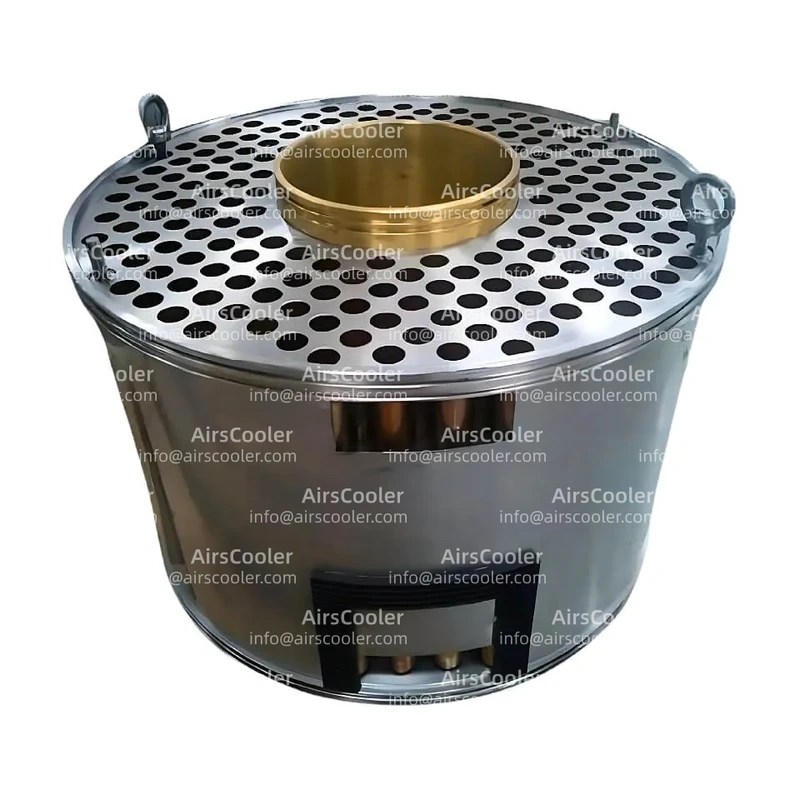

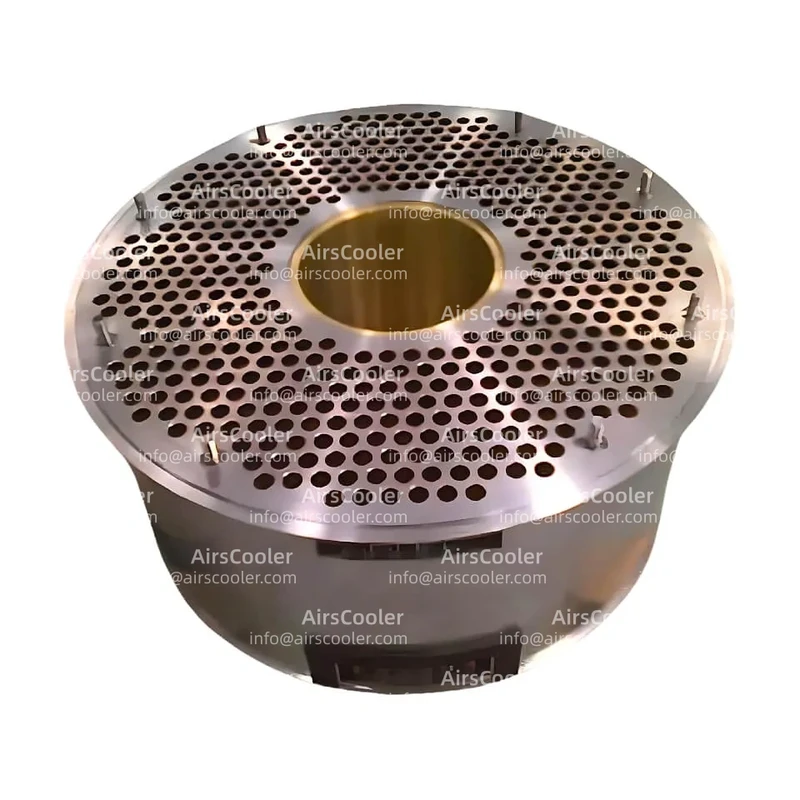

Centac Cooler 3CII

Comprehensive technical specifications and operational guidelines for the high-performance Centac Cooler 3CII from Ingersoll Rand, designed for CENTAC series centrifugal air compressors.

I. Product Overview

The Ingersoll Rand Centac Cooler 3CII is a core heat exchange module specifically built for CENTAC series centrifugal air compressors, primarily used in large-scale industrial use cases such as steel metallurgy, petrochemical, and power generation. Its primary function is to efficiently minimize compressed air temperature, ensuring stable compressor operation while improving system setup overall efficiency and extending equipment lifespan.

II. Technical Features and Data Analysis

1. Heat Dissipation operational performance

| Parameter | Specification |

|---|---|

| Heat transfer area | 50-70 m² per unit (30-40% improvement over traditional designs) |

| Temperature reduction | Stable outlet temperature within 10°C above surrounding (90%+ overall efficiency at 150°C inlet, 200m³/min flow) |

| Heat transfer coefficient | Aluminum alloy: 280-350W/(m²·°C); Copper alloy: 450-600W/(m²·°C) |

| Thermal load capacity | Maximum 1200kW for high-load conditions |

2. Materials and Construction

| module | Specification |

|---|---|

| Aluminum alloy | 5052-H32 aluminum plate (Tensile strength ≥210MPa, Density 2.68g/cm³, 30-35% lighter than copper) |

| Copper alloy | T2 copper tube + 0.2mm aluminum fin composite (Thermal conductivity 401W/(m·K), 4.5MPa pressure tested) |

| Flow channels | Gas side: 8-10mm equivalent diameter; Water side: 12-14mm equivalent diameter (3.0-5.0m/s flow velocity) |

| Sealing system setup | Four-stage graphite ring seal (Leakage ≤0.05SCFM, Oil-gas separation overall efficiency ≥99.999%) |

III. use case Scenarios

1. Petrochemical Industry

- Ethylene cracking: keep 99.8% ethylene yield by cooling 1.0MPa, 160°C gas to 50°C

- Ammonia synthesis: Withstands 2.5MPa pressure with ±1.0°C temperature stability

2. Steel Metallurgy

- Blast furnace: Cools 0.5MPa, 220°C air to 110°C, improving TRT overall efficiency by 12%

- Converter steelmaking: Handles 0.3MPa, 150°C dust-laden gas with ≥99.5% dust removal

IV. Maintenance Strategies

1. Routine Inspection

| Check Item | Standard |

|---|---|

| Cooling water quality | pH 6.8-7.5, Conductivity ≤500μS/cm, Hardness ≤70ppm CaCO₃ |

| Leak detection | ≤5×10⁻¹⁰Pa·m³/s with helium mass spectrometer |

| Vibration analysis | Axial ≤1.5mm/s, Radial ≤2.5mm/s |

V. Technical Upgrades

The Centac Cooler 3CII is evolving with digital and green technologies:

- Digital twin modeling minimizes design iteration by 40%

- AI diagnostics achieve ≥96% fault recognition accuracy

- Hydrogen-resistant Ti-6Al-4V alloy for 60MPa hydrogen use cases

VI. Conclusion

The Ingersoll Rand Centac Cooler 3CII provide superior heat dissipation, high-pressure resistance, and minimal leakage for industrial compressed air system setups. With proper maintenance and digital upgrades, users can achieve 30% extended lifespan and 20% minimized energy consumption. Future developments will focus on green and smart technologies to support industrial energy conservation.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler CV1A

View Details

View DetailsCentac Cooler CV1B

View Details

View DetailsCentac Cooler CV2

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.