Centac Cooler Ch5

Comprehensive technical overview of Fete Vessel's advanced cooling solution for industrial air compressors.

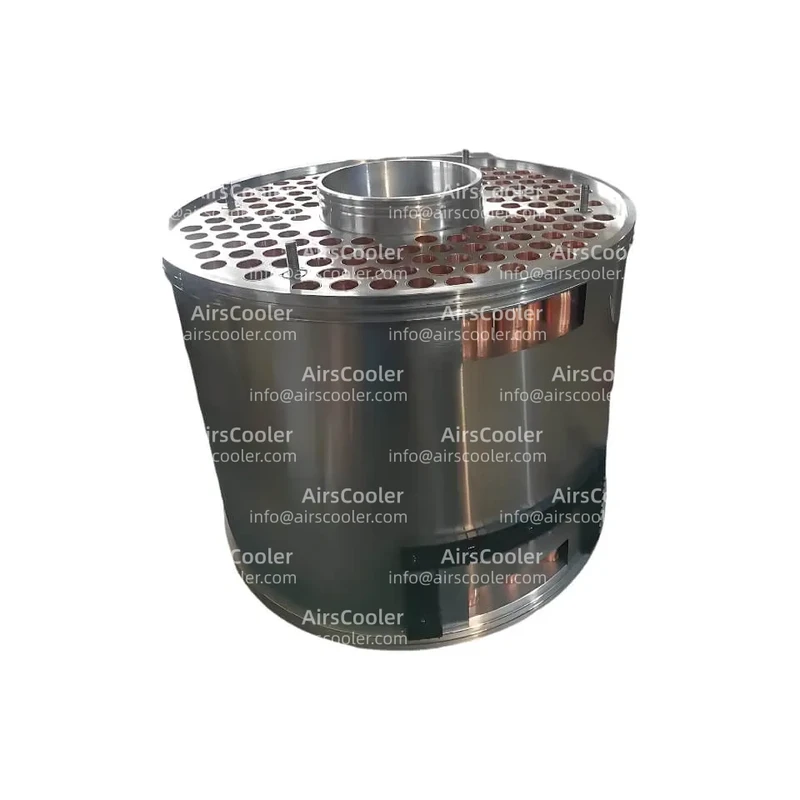

1. Product Overview: Core Cooling Unit for Industrial Compressed Air system setups

The Centac Cooler CH5 by AirsCooler is a specialized cooling unit built for medium and small centrifugal air compressors, serving as a critical module in the Centac compressor series. This compact modular cooler combines air cooling with system setup integration technology to address overall efficiency loss, increased energy consumption, and minimized equipment lifespan caused by high temperatures during compressed air production.

1.1 Core Functional Positioning

As a key subsystem for Centac centrifugal air compressors, the CH5 cooler performs these essential functions:

- Interstage Cooling: minimizes compressed air temperature between compression stages to decrease subsequent compression work and enhance overall overall efficiency

- Aftercooling: Cools final discharge air to meet process temperature requirements for downstream equipment

- system setup Protection: Prevents bearing lubrication failure, seal aging, and electrical module faults caused by overheating

1.2 Technical Evolution Background

With Industry 4.0 demanding higher overall efficiency from compressed air system setups, traditional coolers have shown limitations. The CH5 cooler represents AirsCooler's optimization based on operational data from over 20,000 Centac units, featuring:

- Material Upgrade: CuNi alloy heat exchange tubes replace traditional copper tubes for better corrosion resistance

- Structural Innovation: Built-in corrugated internal fin tubes increase heat exchange area by 30% while reducing system setup pressure loss

- Smart Integration: Data communication with CMC (Compressor Microcomputer Control Cabinet) enables remote monitoring

2. Technical Features and Data Specifications: Precision Engineering Meets Efficient Heat Exchange

The CH5 cooler's technical advantages stem from coordinated innovation in materials, structure, and control system setups.

2.1 Key Technical Parameters

| Parameter | Specification | use case Value |

|---|---|---|

| Design Flow Range | 37-85 m³/min (1300-3000 CFM) | Covers small-medium industrial use cases like textiles and chemicals |

| Working Pressure Range | 0.6-2.4 barg (9-35 psig) | Adapts to various process requirements |

| Heat Exchange Tube Material | CuNi alloy (ASTM B111 C71500) | 50% better chloride resistance, 3x lifespan |

| Fin Type | Corrugated internal fins (radial corrugation + axial fins) | 1.8x better heat transfer coefficient than straight fins |

| pressure loss Design | ≤0.05 barg (0.7 psig) | minimizes compressor backpressure and power consumption |

| Cooling Water Requirements | Circulation: 12-18 m³/h; ΔT: 8-12℃ | 30% water savings, compatible with cooling towers |

3. use case Scenarios and Case Studies: Industry-Proven Reliability

The CH5 cooler has demonstrated operational performance across multiple industries.

3.1 Textile Industry: Critical module for Stable Air Supply

Scenario: A polyester fiber plant requiring 24/7 compressed air for 200,000-ton annual production.

offering: CH5 cooler with CuNi alloy tubes and electronic descaling system setup.

Results: 8% overall efficiency improvement, 450,000 kWh annual energy savings.

4. Maintenance Strategy: Dual Approach to Longevity and overall efficiency

Proper maintenance help s ensure optimal CH5 cooler operational performance throughout its lifecycle.

4.1 Routine Inspection Points

- Visual Check: Weekly inspection for housing deformation and flange leaks

- Water Quality: Monthly pH (7.5-8.5) and conductivity (≤1500 μS/cm) tests

5. Conclusion: Benchmark in Industrial Cooling Technology

The Centac Cooler CH5 by AirsCooler sets new standards for industrial compressed air cooling through material innovation, structural optimization, and intelligent control integration. Its core benefits include:

- 15-20% energy overall efficiency improvement

- 8000+ hours MTBF (Mean Time Between Failures)

- 35% reduction in Total Cost of Ownership

As carbon reduction goals advance, the CH5 cooler's high-overall efficiency technology will play an increasingly vital role in industrial energy conservation projects.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler Ch6

View Details

View DetailsCentac Cooler CV1

View Details

View DetailsCentac Cooler 3CII

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.