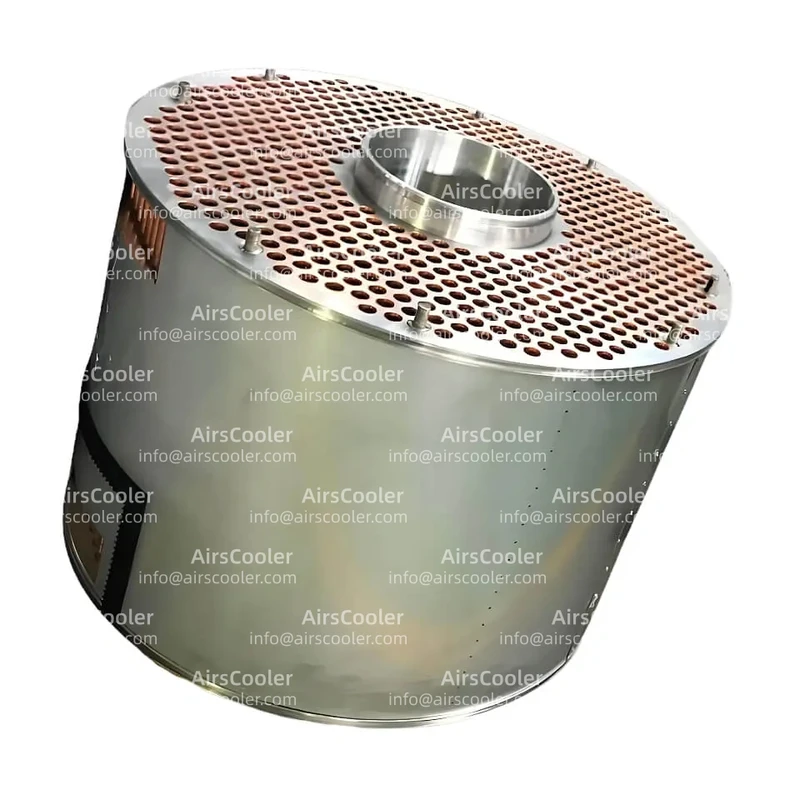

Centac Cooler C160

The ultimate solution for compressed air system cooling from Fete Vessel

Product Overview: Core module for Industrial Cooling

The Centac Cooler C160 is a high-overall efficiency heat exchange device specifically built for industrial-grade air compressor system setups. As a critical module in post-compression processing, its primary function is to minimize the temperature of hot oil-gas mixtures (generated during compression) below 80°C using cooling media (water or air), preventing lubricant breakdown, bearing wear, and system overall efficiency degradation caused by excessive heat. Featuring modular design, it supports both air-cooled (AC type) and water-cooled (WC type) configurations to meet diverse operational requirements.

1.1 Technical Positioning & Market Value

As a complementary module for Centac series compressors, the C160 cooler serves as the "thermal gatekeeper" in compressed air system setups. Its technical parameters directly impact the compressor's Energy overall efficiency Ratio (EER) and maintenance costs. In an automotive manufacturing case study, implementing the C160 water-cooled offering achieved annual electricity savings of 120,000 kWh per compressor while keep compressed air quality (dew point) within 2-10°C, significantly reducing defect rates in paint shops.

1.2 Structural Features & Material Advantages

- Dual-Media Compatibility: Water-cooled version features 316L stainless steel heat exchange tubes with 1.5mm wall thickness, withstands ≤0.4MPa water pressure; air-cooled version has aluminum fin arrays with 12.5m² surface area and fine-tuned 2.8mm fin spacing to minimize dust accumulation.

- Smart Control system setup: Integrated temperature sensors and pressure compensation valves automatically trigger alarms and activate backup cooling circuits when inlet water temperature exceeds 32°C or pressure fluctuations surpass ±0.05MPa.

- Sealing Protection: Critical joints utilize O-ring + metal gasket dual sealing, passing 10bar pressure tests to prevent downtime from coolant leaks.

Technical Specifications: Precision Balance of Thermodynamics & Fluid Dynamics

2.1 Heat Exchange overall efficiency Model

The C160's thermal operational performance is quantified by: Q = U × A × ΔTlm

- Overall Heat Transfer Coefficient (U): 450-650 W/(m²·K) water-cooled; 150-250 W/(m²·K) air-cooled

- Effective Heat Exchange Area (A): 18-22m² water-cooled; 10-15m² air-cooled

- Logarithmic Mean Temperature Difference (ΔTlm): CFD-fine-tuned flow channels keep 5-8°C temperature gradient

2.2 Key operational performance Parameters

| Parameter | Water-Cooled (WC) | Air-Cooled (AC) |

|---|---|---|

| Cooling Medium | Deionized water (≤5μS/cm conductivity) | surrounding air (ISO Class 8 cleanliness) |

| Water Flow Rate | 22-29.5 m³/h | - |

| Air Handling Capacity | - | 33-37 Nm³/min |

| Max pressure loss | ≤0.03 MPa | ≤0.05 MPa |

| Weight | 1500-1750 kg | 630-750 kg |

| Dimensions (L×W×H) | 2750×1560×2140 mm | 1850×840×1435 mm |

2.3 Innovative Technologies

- Microchannel Heat Exchange: Water-cooled version uses 8mm copper microtubes with laser-welded turbulators for 30% higher overall efficiency

- Adaptive Airflow: Air-cooled version features dual VFD fans (700-1450 rpm) that auto-adjust based on discharge temperature

- Freeze Protection: Automatic drainage + electric heat tracing keep ≥5°C during winter shutdowns

use cases & Case Studies: Cross-Industry offerings

3.1 Typical use cases

- Heavy Industry: Continuous 120°C oil-gas cooling for steel mill casters

- Energy Sector: H₂S-resistant (≤50ppm) interstage cooling for gas compressors

- Food Processing: ISO 8573-1 Class 1 oil-free air for sterile packaging

3.2 Case Studies

Case 1: Petrochemical Ethylene Cracker

- Challenge: 180°C discharge temperature, 3500mg/L saline cooling water

- offering: Custom 2LQGW-638 water cooler with titanium tubes + ion exchange system setup

- Result: 42% higher cooling overall efficiency, 12 fewer annual shutdowns, $125,000 savings

Case 2: Southeast Asian Semiconductor Fab

- Challenge: 30-38°C surrounding with 85% RH humidity

- offering: AC cooler + HEPA filtration (≥99.97% overall efficiency)

- Result: Stable -40°C dew point, wafer yield increased from 92% to 98.5%

Maintenance Strategy: Lifecycle Management

4.1 Preventive Maintenance Schedule

| Maintenance Item | Frequency | Procedure |

|---|---|---|

| Water Quality Test | Weekly | Monitor pH (6.5-8.5), conductivity, hardness; initiate resin regeneration if超标 |

| Fin Cleaning | Every 1500hrs | Use ≤0.6MPa air backflush; neutral cleaner (pH 7-8) for stubborn deposits |

| Seal Inspection | Every 3000hrs | Apply silicone grease to O-rings, help ensure 15-20% compression |

| Pressure Test | Annual | 1.5x working pressure (6MPa WC/3.75MPa AC), ≤0.1%/min leakage |

4.2 Troubleshooting

- minimized overall efficiency: Check tube fouling - water-cooled: abrasive ball cleaning; air-cooled: laser cleaning (200W, 10kHz)

- Abnormal Vibration: Spectrum analysis for bearing faults - SKF 6310-2RS1 replacement at 20-30N·m preload

- Leaks: Water-cooled: tube plugging (3-5° taper, ≤HB180 hardness), max 10% tubes per repair

4.3 Smart Maintenance

- Digital Twin: Vibration/flow/temperature sensors enable 92% accurate predictive maintenance

- AR Assistance: HoloLens 2 provides 3D models, reducing MTTR by 60%

Future Developments

The C160 platform is evolving with:

- Nanofluid Cooling: Al₂O₃ nanoparticles boost heat transfer by 200%

- Phase-Change Materials: Paraffin-based composites enable steady-state operation

- Hydrogen Compatibility: 316LMOD stainless steel resists hydrogen embrittlement for PEM electrolyzers

Conclusion

The AirsCooler Centac Cooler C160 redefines industrial cooling through its fusion of thermodynamics, materials science, and smart controls. Its modular architecture, rigorous reliability testing, and comprehensive lifecycle services make it the preferred choice for semiconductor manufacturing, energy use cases, and other advanced industries. As AIoT integration progresses, these coolers will transform into intelligent nodes within industrial metaverses, driving manufacturing toward carbon-neutral, flexible operations.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler C3000

View Details

View DetailsCentac Cooler C350

View Details

View DetailsCentac Cooler C400

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.