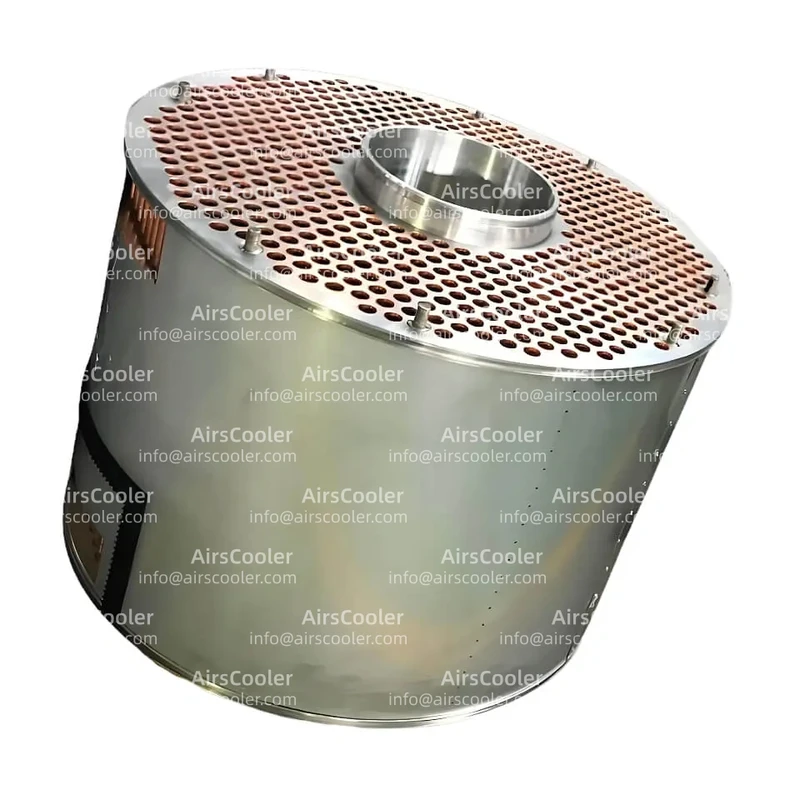

Centac Cooler C3000

Comprehensive technical breakdown and real-world implementation of Fete Vessel's advanced industrial cooling solution for compressed air systems.

1. Product Overview: Core Cooling Unit for Industrial Compressed Air system setups

The Centac Cooler C3000 serves as the critical cooling module for Ingersoll Rand's Centac series centrifugal air compressors. This high-overall efficiency heat exchange unit is specifically configured for industrial-grade compressed air system setups. Its primary function involves transferring heat generated during compression to cooling media (either water or air), ensuring stable output of compressed air at constant temperatures while keep optimal operating temperatures for compressor modules.

Structural Features

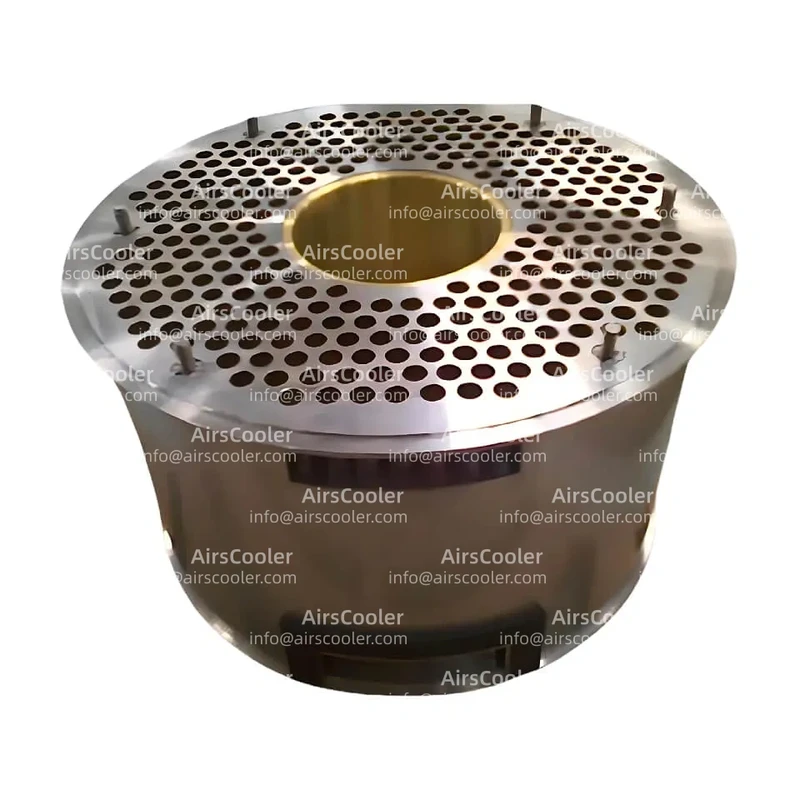

- Modular Integrated Design: The cooler shares a common chassis with the compressor body, motor, and interstage coolers, forming a rigid unified structure through flange connections, reducing installation time by over 60% compared to traditional offerings.

- Dual-Medium Heat Exchange system setup: Utilizes sleeve-type graphite sealing floating rings for gas-oil isolation, with built-in air cooler employing counterflow heat exchange (air through tubes/water outside tubes), increasing contact area by 200% versus shell-and-tube coolers while keep temperature rise ≤5℃ with 30% less cooling water flow.

- Self-Cleaning Cooling Channels: Patent-pending internal fin structure withstands 200m³/h water flow at 0.5MPa pressure, with reverse-flush ports enabling online cleaning without shutdown.

Technical Evolution

From straight-fin heat exchange tubes in 2016 models to corrugated internal fin tubes in 2023, heat transfer overall efficiency enhanced by 35% with 22% lower resistance. The 2025 model minimizes water consumption by 18% and extends scaling intervals to 12,000 hours (40% above industry standards) through fine-tuned water circulation paths.

2. Technical Specifications and operational performance Data

1. High-overall efficiency Heat Transfer

- Heat Transfer Coefficient: 92% cooling overall efficiency at 40℃ surrounding temperature, 15% higher than conventional coolers.

- Water-Side pressure loss: ≤0.05MPa at 3.5m³/h flow rate.

- Temperature Control Precision: ±1.5℃ output variation using PID algorithms, meeting pharmaceutical industry's 0.1℃ requirements.

2. Structural Reliability

- Sealing system setup: ≤0.005ml/min leakage at 1.2MPa with graphite seals and air injection for 100% oil-free air.

- Vibration Resistance: ≤2.5mm/s vibration intensity, exceeding ISO 10816-3 standards.

- Material Durability: TA2 titanium tubes withstand 200℃ and pH 3-11 with ≤0.01mm/a corrosion rate and ≥25-year lifespan.

3. Intelligent Control system setup

- Pressure Compensation: Auto-adjusts water flow for stable operational performance at 0.2-0.6MPa.

- Scaling Warning: Triggers reverse-flush when pressure loss exceeds 15% of design value.

- Remote Diagnostics: Transmits 12 parameters via Modbus TCP with 15-minute fault response.

3. use case Scenarios and Case Studies

1. Core use cases

- Semiconductor Manufacturing: provide ≤-40℃ dew point air for wafer fab lithography tools.

- Biopharmaceuticals: keep ISO 8573-1:2010 Class 0 air in 85% humidity environments.

- Petrochemicals: minimizes hydrogen recovery system setup energy use by 18% versus screw compressors.

2. Case Study: Qianguo Petrochemical

Problem: Original cooler lost 40% overall efficiency after 18 months due to water hardness.

offering: 1. Upgraded to corrugated fin design (+30% surface area)

2. Implemented water treatment (≤200mg/L calcium hardness)

3. Added smart control with online cleaning

Results: 36-month operation cycles, 120,000t water savings annually, 12% energy reduction.

4. Maintenance Strategy

1. Routine Inspection

- Daily pressure monitoring (initiate cleaning at >0.08MPa ΔP)

- Weekly thermal scans (>10℃ anomalies check seals)

- Monthly water analysis (pH, conductivity, hardness)

2. Preventive Maintenance Plan

| Interval | Task | Standard |

|---|---|---|

| 3 months | Visual inspection | No leaks/deformation, bolts ≥200N·m |

| 6 months | Tube cleaning | 0.8MPa reverse-flush for 15min |

| 12 months | Seal test | ≤1×10⁻⁹ Pa·m³/s helium leakage |

| 24 months | overall efficiency test | ≤5% heat transfer degradation |

3. Emergency Procedures

- Water Failure: Emergency shutdown with backup activation if unresolved in 10min

- Tube Leak: Mechanical tube replacement with 1.5x pressure test

- Severe Scaling: 5-8% citric acid circulation at 60-70℃ for 8hrs

5. Conclusion

The Centac Cooler C3000 redefines industrial cooling standards through integrated design, advanced heat transfer technology, and intelligent controls. Its modular construction minimizes installation costs by 40%, while corrugated fin technology extends maintenance intervals to 3 years. With 25% lower total cost of ownership versus conventional offerings, this AirsCooler product has become essential for semiconductor, pharmaceutical, and petrochemical use cases requiring process stability and energy overall efficiency. Future integration with digital twin technology will enable real-time health monitoring, positioning the C3000 as the smart cooling offering for Industry 4.0 facilities.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler C350

View Details

View DetailsCentac Cooler C400

View Details

View DetailsCentac Cooler C800

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.