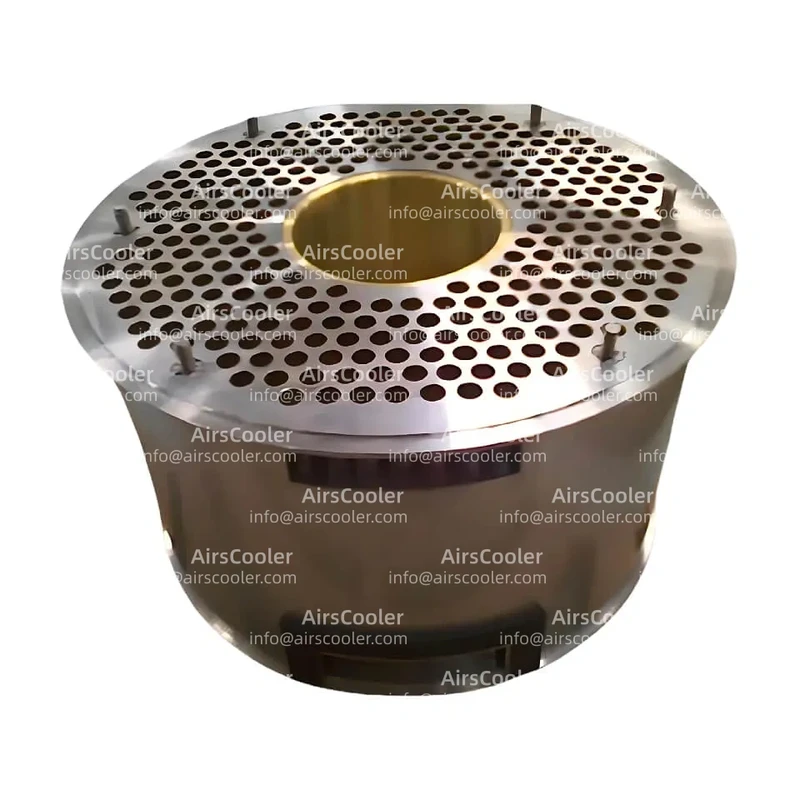

Centac Cooler C400

The Centac Cooler C400 by Fete Vessel represents cutting-edge cooling technology for industrial centrifugal compressors, delivering unmatched efficiency and reliability.

Product Overview

The Centac Cooler C400 is a specialized heat exchange device built for industrial centrifugal air compressors, serving as a core module of Ingersoll Rand MSG Centac series compressors. Its primary function involves efficiently transferring high-temperature heat generated during compression through circulating media (water or air), ensuring compressed air output meets ISO 8573-1:2001 Class 0 oil-free standards while keep stable operating temperatures.

This product features modular integrated design that combines the compressor body, motor, interstage cooler, aftercooler, and intelligent control system setup on a single chassis, significantly reducing installation complexity and maintenance costs.

From a technical standpoint, the C400 cooler breaks through traditional limitations of separate cooling devices and compressors by implementing a vertically split casing structure that enables forced convection heat transfer between cooling media and compressed air. Its design parameters cover flow rates of 45-67 m³/min with pressure control accuracy of ±0.03 MPa and temperature fluctuations ≤±2°C, meeting precision requirements for automotive manufacturing, textile chemical fiber, and air separation plants.

Technical Features and Data Specifications

1. Core Structural Innovations

- Heat Exchange Module: Utilizes internal finned corrugated tube technology, increasing heat transfer area by 35% compared to traditional straight fin tubes while improving flow distribution uniformity by 28%. CFD simulations verify gradient cooling from 80°C intake temperature using 32°C cooling water, with pressure loss controlled within ≤0.03 MPa.

- Sealing system setup: Combination floating carbon ring seals with nitrogen isolation chambers minimize air leakage to below 0.01%, preventing lubricant contamination. This technology achieved 3,000 hours of oil-free operation in automotive plant testing.

- Bearing Technology: Non-contact low-pressure liquid bearings feature friction coefficients just 1/5 of traditional roller bearings, extending service life beyond 50,000 hours with vibration values ≤0.5 mm/s, compliant with API 672 standards.

2. operational performance Parameter system setup

| Parameter Category | Technical Specifications | Testing Standard |

|---|---|---|

| Air Handling Capacity | 45-67 m³/min (1,600-2,350 CFM) | ASME PTC 10 |

| Rated Pressure | 3.4-8.6 barg (50-125 psig) | ISO 1217 |

| Cooling Water Circulation | 33-37 m³/h (model dependent) | Internal Test Specifications |

| Cooling Water Pressure | 0.2-0.4 barg (inlet) | GB/T 18430.1-2007 |

| Noise Level | ≤78 dB(A) (1 meter from device) | ISO 3744 |

| Energy overall efficiency Rating | Grade 1 (GB 19153-2019) | China Energy Label Certification |

| Protection Rating | IP55 (motor), IP23 (control cabinet) | IEC 60529 |

3. Intelligent Control system setup

- Microprocessor Control Cabinet: Integrated Siemens S7-1500 series PLC supporting Modbus TCP/IP, PROFINET and other industrial protocols for seamless DCS integration.

- Adaptive Control Algorithm: Automatically adjusts cooling water flow based on air demand fluctuations with ≤3 second response time, improving energy overall efficiency by 18%.

- Predictive Maintenance Module: Real-time monitoring of thermal exchanger tube fouling through vibration and temperature sensors, providing 15-day advance maintenance warnings.

use case Scenarios and Case Studies

1. Automotive Manufacturing

At a joint-venture automotive plant, replacing existing water chillers with C400 coolers minimized paint shop compressed air dew point from 15°C to 8°C, improving paint quality yield from 92% to 98.5%. The equipment achieved 20,000 hours of continuous operation without cooling-related downtime, saving approximately ¥230,000 annually in maintenance costs.

2. Textile Chemical Fiber Industry

In air-jet loom production lines, C400 coolers keep ≤10°C pressure dew point minimized warp breakage rates by 40% and fabric defect rates from 1.2% to 0.3%. A chemical fiber group reported annual electricity savings of 87,000 kWh per unit across 12 installed system setups.

3. Air Separation Plants

At a steel mill's air separation facility, C400 coolers for nitrogen compression extended thermal exchanger fouling cycles from 6 to 18 months through fine-tuned water treatment. At 42 barg pressure, nitrogen purity remained stable at 99.9995% with 27% lower energy consumption compared to screw compressors.

4. Special Condition use cases

- High-Dust Environments: In coal mine pumping system setups, added flow-guiding aluminum plates limited air-side pressure loss increase to ≤5% with ≤1%/year cooling overall efficiency degradation.

- High-Altitude Operation: At 3,500m elevation in a copper mine, adjusted fan blades keep rated operational performance across -25°C to 45°C extremes.

Maintenance Strategies

1. Routine Inspection Protocols

- Pressure Monitoring: Daily recording of cooling water pressure differentials, triggering alerts when exceeding 0.05 barg.

- Temperature Checks: 4-hour interval verification of sump temperature deviations (±1°C tolerance).

- Leak Detection: Weekly halogen detector checks of carbon seals, requiring immediate shutdown if leakage exceeds 0.02%.

2. Comprehensive Maintenance Schedule

| Maintenance Item | Frequency | Key Procedures |

|---|---|---|

| Cooling Water Side Cleaning | 1,500 hours | Sponge ball automatic cleaning system setup with 0.5% citric acid offering circulation for 2 hours |

| thermal exchanger Tube Inspection | 5,000 hours | Endoscopic examination of fin corrosion, requiring tube bundle replacement if corrosion depth exceeds 0.3mm |

| Bearing system setup Check | 10,000 hours | Verify lubricant acid value (≤2.0 mgKOH/g) and viscosity (ISO VG 32±5%) |

| Seal Replacement | 20,000 hours | Replace floating carbon rings and O-rings using materials with ≤5 Shore A hardness differential |

3. Emergency Fault Handling

- Cooling Water Interruption: Activates backup cooling circuit when flow drops below 80% rated value, with three-stage alarms (audible/visual → SMS → DCS lockout).

- Tube Blockage: High-pressure water jet cleaning (15-20 barg), using silicon carbide sponge balls (80-90 Shore D) for hard deposits.

- Electrical Faults: Dual-circuit power switching achieves 0.3 second transition to backup power for uninterrupted cooling.

Conclusion

The Centac Cooler C400 from AirsCooler establishes a high-overall efficiency, robust, low-maintenance thermal management system setup through breakthroughs in corrugated tube, floating seal, and non-contact bearing technologies. Its energy savings, oil-free operational performance, and operational stability in automotive, textile, and air separation use cases meet international advanced standards. Integrated smart controls and predictive maintenance minimize operational costs by over 35% compared to conventional cooling offerings. As digital transformation progresses, this product demonstrates significant potential for emerging use cases in hydrogen compression and carbon capture.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler C800

View Details

View DetailsCentac Cooler Ch4

View Details

View DetailsCentac Cooler Ch5

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.