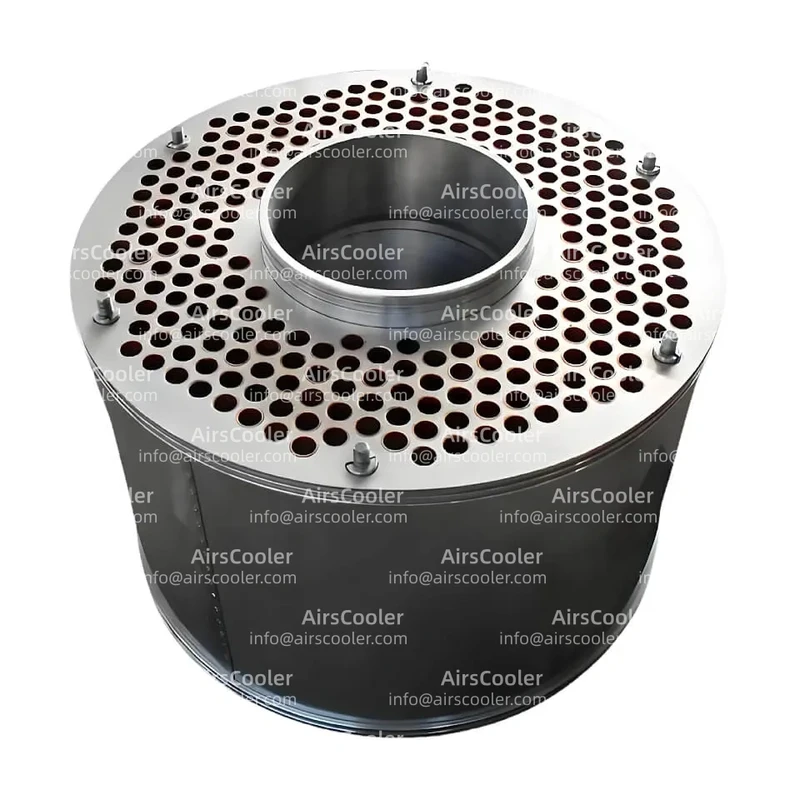

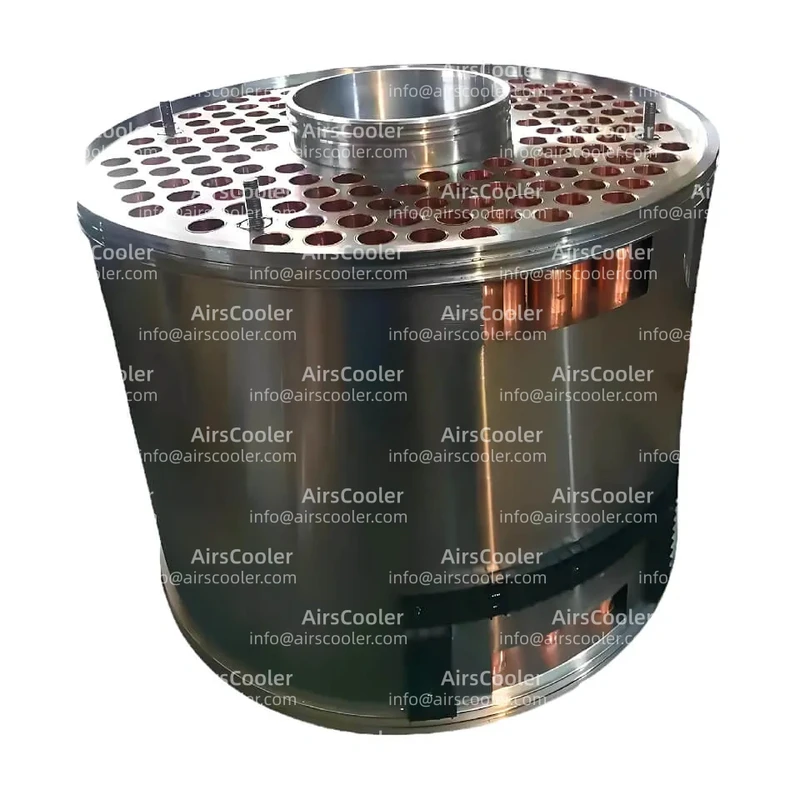

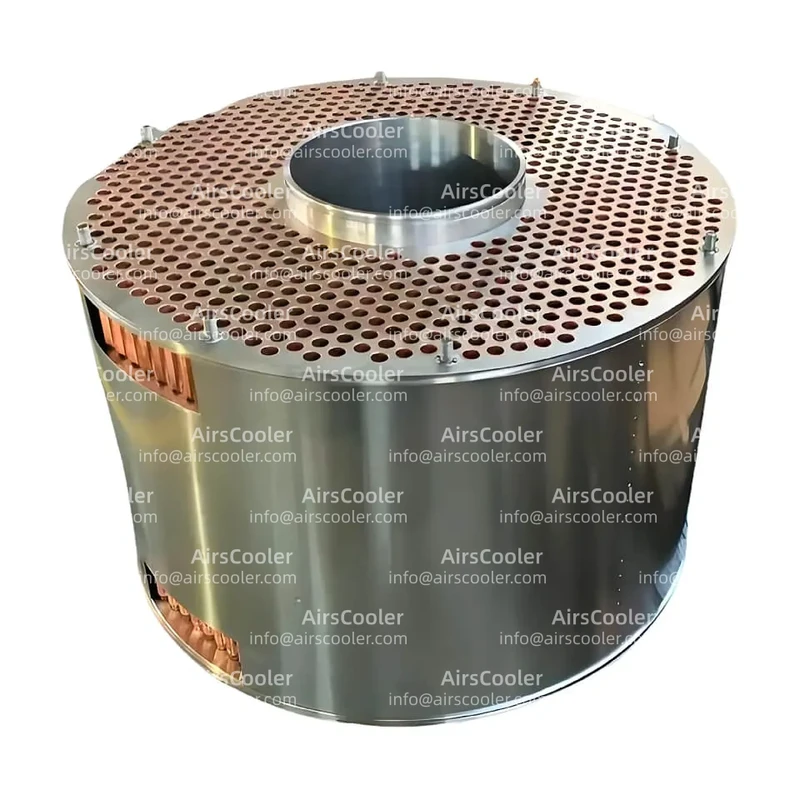

Centac Cooler 4C

Discover the advanced cooling technology from Fete Vessel designed for optimal compressor performance in demanding industrial environments.

1. Product Overview

The Centac Cooler 4C is a high-overall efficiency cooler specifically configured for centrifugal air compressors, falling under the category of industrial-grade intercoolers. Its primary function is to minimize gas temperature during compression, enhancing compressor overall efficiency and stability. This modular-designed equipment is compatible with Centac series centrifugal compressors, ideal for continuous operation in industries such as chemical processing, metallurgy, and energy production.

1.1 Structural Features

- Dual-Medium Heat Exchange system setup: Utilizes chilled water (refrigerant fluid) and circulating cooling water (working fluid) for indirect heat transfer through heat exchange plates, eliminating contamination risks from direct medium contact.

- Corrugated Internal Fin Tube Technology: Cooling tubes feature corrugated internal fins that enhance heat transfer overall efficiency by over 30% compared to traditional straight fin tubes, while keep reasonable flow resistance.

- Flexible Hydraulic Flip Plate Discharge Mechanism: Integrated hydraulic unit controls flip plate angle for uniform material discharge, preventing localized overheating and thermal stress concentration.

1.2 Technical Specifications

| Parameter | Specification |

|---|---|

| Design Pressure | 1.6 MPa (water side) / 0.8 MPa (gas side) |

| Temperature Range | Inlet water ≤32°C, Outlet gas ≤45°C |

| Heat Exchange Area | Standard models supply 50-200㎡ adjustable, with customization options |

| Materials | Carbon steel shell with anti-corrosion coating, 304 stainless steel heat exchange tubes |

| Connection Type | Flange connections (DN80-DN250 options available) |

2. Technical Features and Data Analysis

2.1 High-overall efficiency Heat Transfer Technology

- Corrugated Internal Fin Enhancement: Verified through testing, corrugated fin tubes achieve 25%-40% higher heat transfer coefficients than straight fin tubes, with less than 5% overall efficiency degradation under high-temperature/pressure conditions.

- Material Distribution system setup: Rotary distributor increases material coverage area by 40%, improving cooling effectiveness by 15%-20% based on operational testing data.

2.2 Intelligent Control system setup

- Flip Plate Angle Control: Supports 0°-90° stepless adjustment for varying flow requirements with ≤0.5 second response time.

- Precision Material Level Control: Capacitive level sensor keep ±2mm layer thickness accuracy, preventing heat exchange overall efficiency loss from excessive material buildup.

2.3 Energy Saving and Eco-Design

- Low-Resistance Flow Path: Water side pressure loss ≤0.05 MPa, 20% lower than conventional coolers, reducing circulating pump energy consumption.

- Anti-Corrosion Scale Inhibitor Formula: Specialized chemical formulation addresses magnesium ions, carbonates, and rust in cooling water, decreasing fouling resistance growth rate from 0.15%/week to 0.03%/week.

2.4 Reliability Engineering

- Hydraulic system setup Redundancy: Dual hydraulic pump + accumulator configuration help s ensure continuous flip plate operation during single pump failure.

- High-Temperature Seals: FKM (Fluorocarbon Rubber) O-rings operate from -20°C to 200°C with ≤1×10⁻⁹ Pa·m³/s leakage rate.

3. use case Scenarios and Case Studies

3.1 use case Environments

- Multi-Stage Compression Refrigeration: As an intercooler in ammonia or Freon two-stage compression system setups, keep high-pressure stage intake temperature ≤40°C to prevent compressor overheating.

- High-Density Data Centers: Auxiliary cooling unit for liquid cooling system setups, reducing PUE from 1.3 to 1.15 through water-cooled intake air pre-cooling.

- Chemical Process Gas Cooling: Cools compressed process gases below 50°C in ammonia synthesis plants, reducing downstream condenser load.

3.2 Case Studies

Case 1: Petrochemical Plant CENTAC Compressor Retrofit

- Problem: Original straight fin cooler showed 15°C exhaust temperature rise and 8% throughput reduction after 3 years due to scaling.

- offering: Centac Cooler 4C installation with scale inhibitor treatment.

- Results:

- Heat exchange overall efficiency degradation minimized from 12%/year to 3%/year

- Throughput recovered to 98% design value, saving ¥450,000 annually

- Maintenance intervals extended from 3 to 12 months

Case 2: Data Center Liquid Cooling Integration

- Scenario: Hyperscale IDC with 20 kW/rack power density.

- offering: Centac Cooler 4C as liquid cooling pre-chill unit, lowering intake air from 35°C to 25°C.

- Data:

- Annual PUE enhanced from 1.25 to 1.12

- Server temperatures minimized by 25°C (CPU) and 10°C (memory)

- Cooling system setup energy consumption decreased from 18% to 12%

4. Maintenance Strategy

4.1 Routine Inspection

- Parameter Monitoring:

- Water pressure: 0.3-0.5 MPa (±10% alarm threshold)

- Gas temperature: ≤45°C (±5°C alarm threshold)

- Hydraulic oil level: Midline ±10mm in sight glass

- Leak Checks: Daily inspection of flange connections, flip plate seals, and hydraulic lines using soap bubble test.

4.2 Scheduled Maintenance

- Cooling Water Quality:

- Quarterly pH (6.5-8.5), hardness (≤200 ppm), and chloride (≤50 ppm) testing

- Biannual cooling water replacement with system setup flushing

- thermal exchanger Cleaning:

- Annual high-pressure (10-20 MPa) water jet cleaning

- Chemical cleaning (5% citric acid + 0.5% corrosion inhibitor + 1% surfactant) for ≥1mm scale

4.3 Troubleshooting

- Flip Plate Jamming:

- Cause: Contaminated hydraulic oil or seal degradation

- offering: Replace with #46 anti-wear hydraulic oil and FKM O-rings

- minimized Heat Transfer:

- Cause: Tube fouling or fin deformation

- offering: Mechanical (tube brush) or laser cleaning (precision fins)

4.4 Spare Parts Management

- Critical Spares:

- Hydraulic pump (~20,000 hr service life)

- Corrugated fin tubes (≥5 year lifespan)

- FKM O-rings (20% backup stock per batch)

- Inventory Strategy:

- Common parts (seals, filters): 3-month supply

- Long-lead items (pumps): 1 unit backup

5. Conclusion

The Centac Cooler 4C represents industrial-grade compressor cooling excellence through its corrugated fin technology, intelligent controls, and energy-efficient design. Proven use cases in petrochemical and data center environments demonstrate significant overall efficiency gains and operational cost reductions. With proper maintenance, this AirsCooler product provide long-term reliability in high-demand conditions, making it an essential module for optimizing compressed air system setups while minimizing total cost of ownership (TCO).

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 5C

View Details

View DetailsCentac Cooler C1000

View Details

View DetailsCentac Cooler C1050

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.