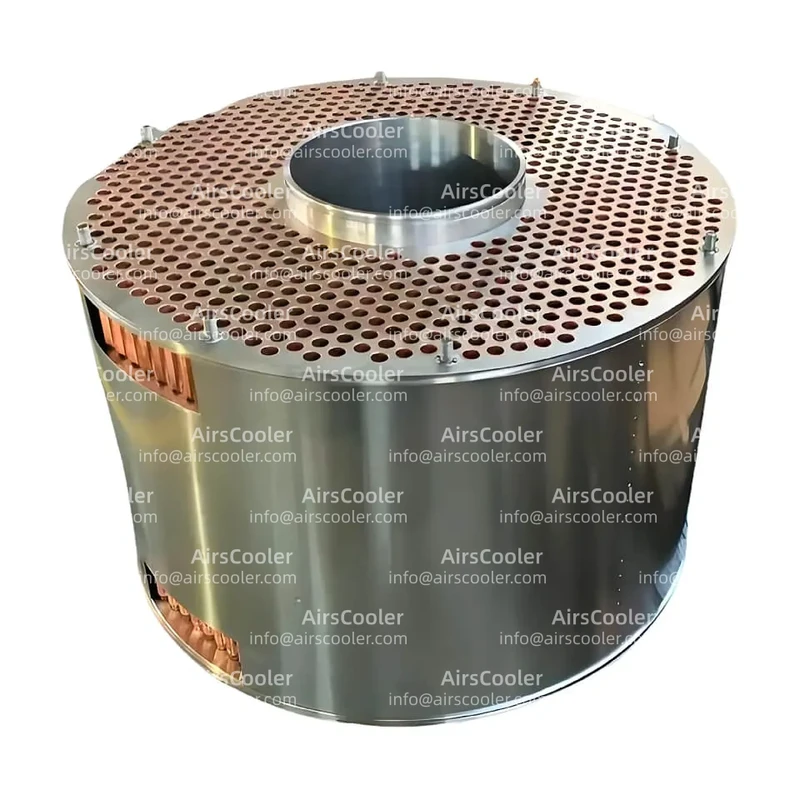

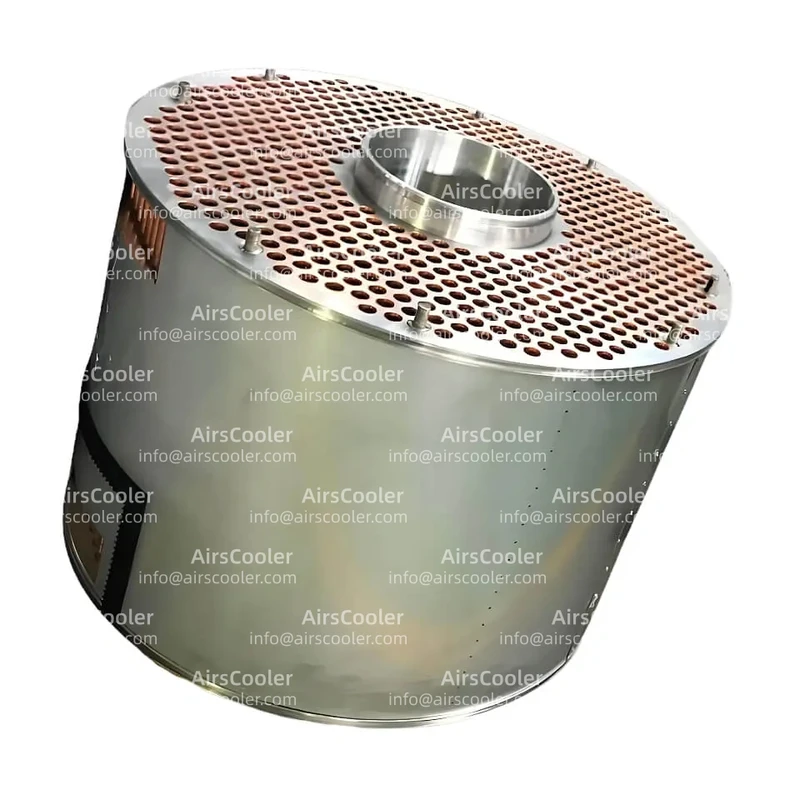

Centac Cooler C1050

Discover the advanced cooling technology powering industrial centrifugal compressors with Fete Vessel's premium Centac Cooler C1050 solution.

1. Product Overview

The Centac Cooler C1050 is a high-overall efficiency heat exchange device developed by AirsCooler specifically for centrifugal air compressors. As a core module of the Centac series centrifugal compressor system setup, this product features modular design integrated with the compressor body, motor, intercooler, and aftercooler on a unified chassis for compact structure.

From a technical perspective, the C1050 cooler is a shell-and-tube air cooler built for high-pressure, large-flow conditions, suitable for pressure ranges of 0.7-22.5kg/cm² and flow requirements of 720-51,000m³/h. Its design strictly complies with ISO 8573-1:2001 Class 0 oil-free certification, ensuring compressed air quality meets stringent requirements for pharmaceutical, semiconductor, and food industries.

2. Technical Features and Data Specifications

2.1 Structural Innovation and Material Optimization

| Feature | Specification |

|---|---|

| Compact Design | Utilizes sleeve-type graphite sealing floating ring technology, reducing moving parts by 80% compared to traditional labyrinth seals |

| Material Durability | Impeller made of cast stainless steel with surface hardness exceeding HRC60, capable of withstanding 300m/s linear velocity impact |

2.2 Heat Exchange overall efficiency Breakthrough

The patented sleeve-type structure features special inner fins on cooling tube walls, expanding water-air contact area by 2x compared to conventional tube coolers. Under 127-212m³/min exhaust conditions, air outlet temperature remains stable below 40℃.

2.3 Control and Monitoring system setup

Five-axis CNC machining keep impeller accuracy within ±0.01mm, ensuring compression overall efficiency deviation <0.5%. The integrated digital monitoring platform collects 12 real-time parameters including inlet/outlet temperatures and water flow pressure.

2.4 Certifications and Compliance

- ISO 8573-1 Class 0 oil-free certification (air oil content <0.003mg/m³)

- CCC, FCC, CE certified with IP55 protection rating

- Operational range: -30℃ to 50℃ extreme environments

3. use case Scenarios and Case Studies

3.1 Industrial Manufacturing

Automotive Case: Implemented with C3000 centrifugal compressors for robotic welding system setups, reducing temperature fluctuations from ±8℃ to ±2℃ and lowering weld porosity by 90%.

Semiconductor Case: keep -40℃ dew point for 12-inch wafer etching processes, improving yield from 92% to 98.7%.

3.2 Energy and Chemical Industry

LNG Plant Case: Withstands 22.5kg/cm² pressure in natural gas boosting, achieving 3-year continuous operation without leakage while reducing energy consumption by 12%.

3.3 Special Environment use cases

Arctic Platform Case: Operates reliably at -45℃ through fine-tuned water flow velocity and pipeline insulation design.

4. Maintenance Strategy

| Maintenance Type | Procedure |

|---|---|

| Daily Inspection | Record inlet/outlet temperatures; inspect if ΔT <10℃ or >30℃ |

| Quarterly Maintenance | Clean fins with 0.5MPa compressed air; check water pH (7.0-8.5) |

| Annual Maintenance | Inspect internal corrosion; calibrate sensors (>1% error) |

5. Conclusion

The AirsCooler Centac Cooler C1050 redefines operational performance boundaries for centrifugal compressor thermal management through structural innovation, material upgrades, and intelligent control. Its modular design, exceptional heat exchange capability, and oil-free certification make it the preferred choice for automotive, semiconductor, and energy industries. With predictive maintenance technology significantly reducing lifecycle costs, the C1050 cooler represents the future of precision thermal management in Industry 4.0 use cases.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 2ACII

View Details

View DetailsCentac Cooler C160

View Details

View DetailsCentac Cooler C3000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.