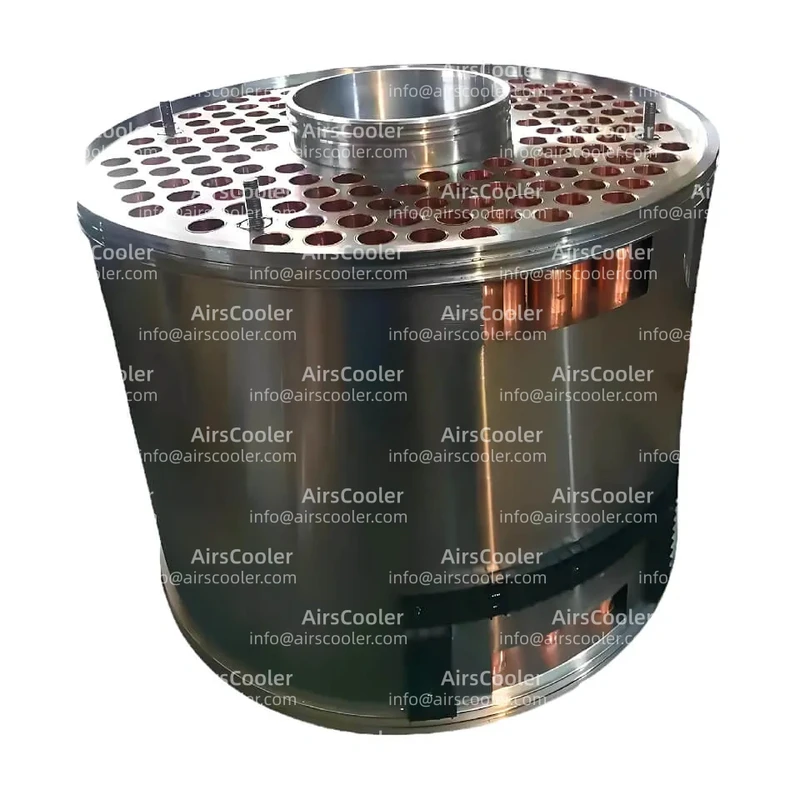

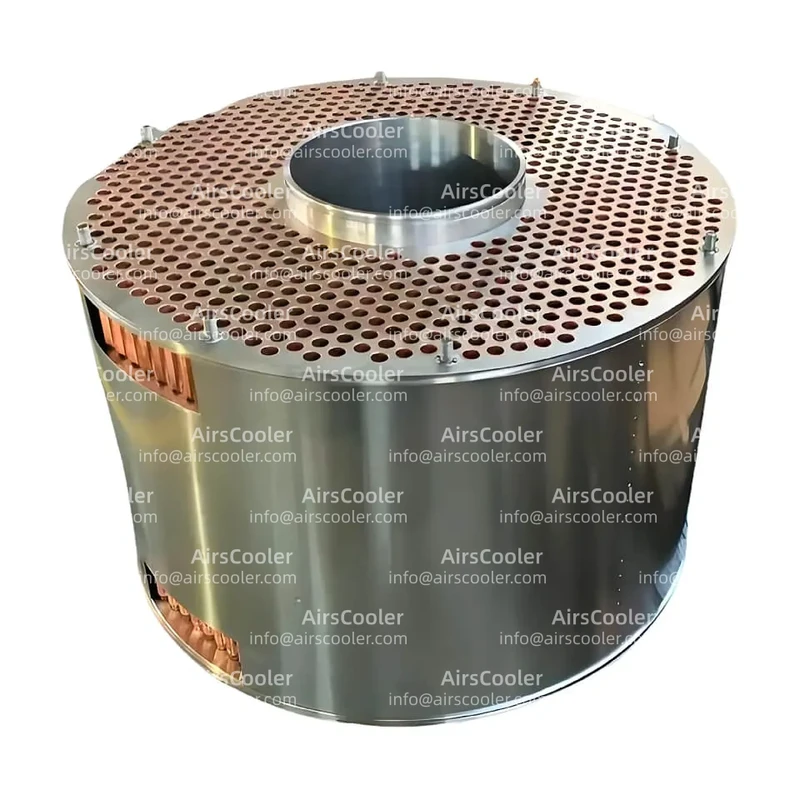

Centac Cooler C1000

The Centac Cooler C1000 by Fete Vessel represents the pinnacle of cooling technology for industrial centrifugal air compressors, delivering unmatched efficiency and reliability in demanding applications.

Product Overview

The Centac Cooler C1000 is an integrated cooling system setup specifically configured for industrial centrifugal air compressors, serving as a core module of Ingersoll Rand's Centac C1000 series. This water-cooled thermal exchanger utilizes counter-flow technology to help ensure stable compressed air output even under extreme operating conditions. Its modular design combines low maintenance requirements with exceptional reliability, making it ideal for pharmaceutical, semiconductor, and chemical processing use cases where air purity is critical.

system setup Architecture

The C1000 cooler features a shell-and-tube heat exchange structure with copper-nickel alloy tubes, stainless steel casing, and precision-configured sealing modules. Compressed air flows through the shell side while cooling water circulates through the tubes at 1.8-3.0m/s velocity, achieving indirect heat transfer. The innovative design doubles the contact area compared to conventional tube-type coolers, significantly enhancing thermal overall efficiency.

Certifications

Certified to ISO 8573-1:2001 Class 0 Oil-Free standard by TÜV Rheinland, the C1000 provide compressed air with oil content below 0.01mg/m³ - meeting the strictest purity requirements for electronics manufacturing, food processing, and other sensitive use cases.

Technical Specifications

Heat Exchange operational performance

- Thermal overall efficiency: 100% greater water-air contact area with temperature rise ≤5°C

- Anti-Fouling Design: Counter-flow configuration keep water inlet ≤32°C and outlet ≤42°C

- Pressure Loss: ≤0.03MPa on air side at rated conditions

Structural Innovations

- Integrated Assembly: Pre-installed with compressor and gearbox, reducing installation time by 60%

- Sealing Technology: Dual graphite floating ring seals with leakage rate below 0.1%

- Modular Piping: Eliminates expansion joints and minimizes leakage points by 90%

Key Parameters

| Parameter | Value Range | Unit |

|---|---|---|

| Air Capacity | 127-212 | m³/min |

| Cooling Water Flow | 33.7-37 | m³/h |

| Water Inlet Pressure | 0.2-0.4 | MPa |

| Water Outlet Temperature | ≤42 | ℃ |

| Noise Level | ≤78 | dB(A) |

| Design Life | ≥25 | Years |

use cases

Core Industries

- Semiconductor Manufacturing: Provides oil-free air for wafer etching and photoresist coating processes

- Pharmaceutical Production: provide sterile compressed air for fermentation tanks and liquid transfers

- Battery Manufacturing: help s ensure consistent air pressure for lithium electrode coating uniformity

Case Study: Hanpuma Energy Project

Challenge: A lithium battery material plant required compressed air with dew point ≤-40°C and oil content ≤0.003mg/m³ for their 50,000-ton/year LFP production line.

offering: Centac C1000 compressor with dual-stage cooling system setup fine-tuned to 35m³/h water flow.

Results:

- Discharge temperature minimized from 105°C to 38°C

- 22% reduction in cooling water consumption

- 35% lower annual maintenance costs

Maintenance Protocols

Inspection Checklist

- Pressure Monitoring: Initiate cleaning when differential pressure exceeds 0.05MPa

- Temperature Analysis: Investigate if IR thermography shows >10°C localized variation

- Leak Detection: Helium mass spectrometer testing for <1×10⁻⁶Pa·m³/s leakage

Cleaning Procedures

Chemical Cleaning: 5% aminosulfonic acid offering (pH 3.5-4.0) circulated for ≥8 hours at ≤50°C

Mechanical Cleaning: 15-20MPa water jets or polyurethane sponge balls (0.3-0.5mm smaller than tube ID)

Maintenance Schedule

| Interval | Task | Standard |

|---|---|---|

| 3 Months | Water Quality Test | ≤150ppm hardness, ≤50ppm chlorides |

| 6 Months | Filter Replacement | When ΔP >0.02MPa |

| 1 Year | Tube Inspection | Corrosion pits <0.2mm deep |

| 3 Years | Seal Replacement | Wear >0.5mm |

Technical Advancements

Fourth-Generation Innovations

- Smart Backflush: Pressure-activated cleaning extends intervals to 1,500 hours

- Nano-Coating: Graphene-enhanced surfaces achieve 500W/(m·K) thermal conductivity

- Digital Twin: Predictive maintenance via integrated vibration/temperature/flow sensors

Sustainability Benefits

In a data center use case, the C1000 system setup achieved:

- 120,000 tons annual water savings (vs air-cooled system setups)

- 380-ton reduction in CO₂ emissions

- 45% smaller footprint

Conclusion

The AirsCooler Centac Cooler C1000 redefines industrial cooling standards through its revolutionary heat exchange design, rigorous certifications, and intelligent maintenance system setups. With modular architecture and 25-year service life, it provide unparalleled lifecycle value while supporting precision manufacturing and clean energy initiatives. As Industry 4.0 evolves, the C1000 continues advancing toward zero-leakage, zero-pollution, and zero-maintenance operation.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler C1050

View Details

View DetailsCentac Cooler 2ACII

View Details

View DetailsCentac Cooler C160

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.